Viking Pump TSM630.2: LS-QS Universal Seal User Manual

Page 9

SECTION TSM 630.2

ISSUE

I

PAGE 9 OF 12

PUMP

SIZE

MODEL

STANDARD

END

CLEARANCE

(Inch)

TURN BRG.

HOUSING

C.C.W.

LENGTH ON

O.D.

(Inch)

ADDITIONAL

LENGTH ON

O.D. BRG.

HOUSING FOR

.001” END CL.

(Inch)

LS

124A

4124A

126A

4126A

123A

4123A

.005

1.25

224A

224AH

4224A

4224AH

226A

4226A

223A

4223A

124E

124EH

.010

2.50

.25

127A

4127A

.010

2.50

227A

4227A

.20

5.00

Q

QS

124A

4124A

126A

4126A

123A

4123A

.010

3.10

224A

4224A

226A

4226A

223A

4223A

124E

.015

4.65

.31

127A

4127A

.010

3.10

227A

4227A

.020

6.20

TABLE 1

When installing carbon graphite bushings, extreme care must

be taken to prevent breaking. Carbon graphite is a brittle

material and easily cracked. If cracked, the bushing will

quickly disintegrate. Using a lubricant and adding a chamfer

on the bushing and the mating part will help in installation.

The additional precautions listed below must be followed for

proper installation.

1. A press must be used for installation.

2. Be certain bushing is started straight.

3. Do not stop pressing operation until bushing is in proper

position. Starting and stopping will result in a cracked

bushing.

4. Check bushing for cracks after installation.

INSTALLATION OF CARBON

GRAPHITE BUSHINGS

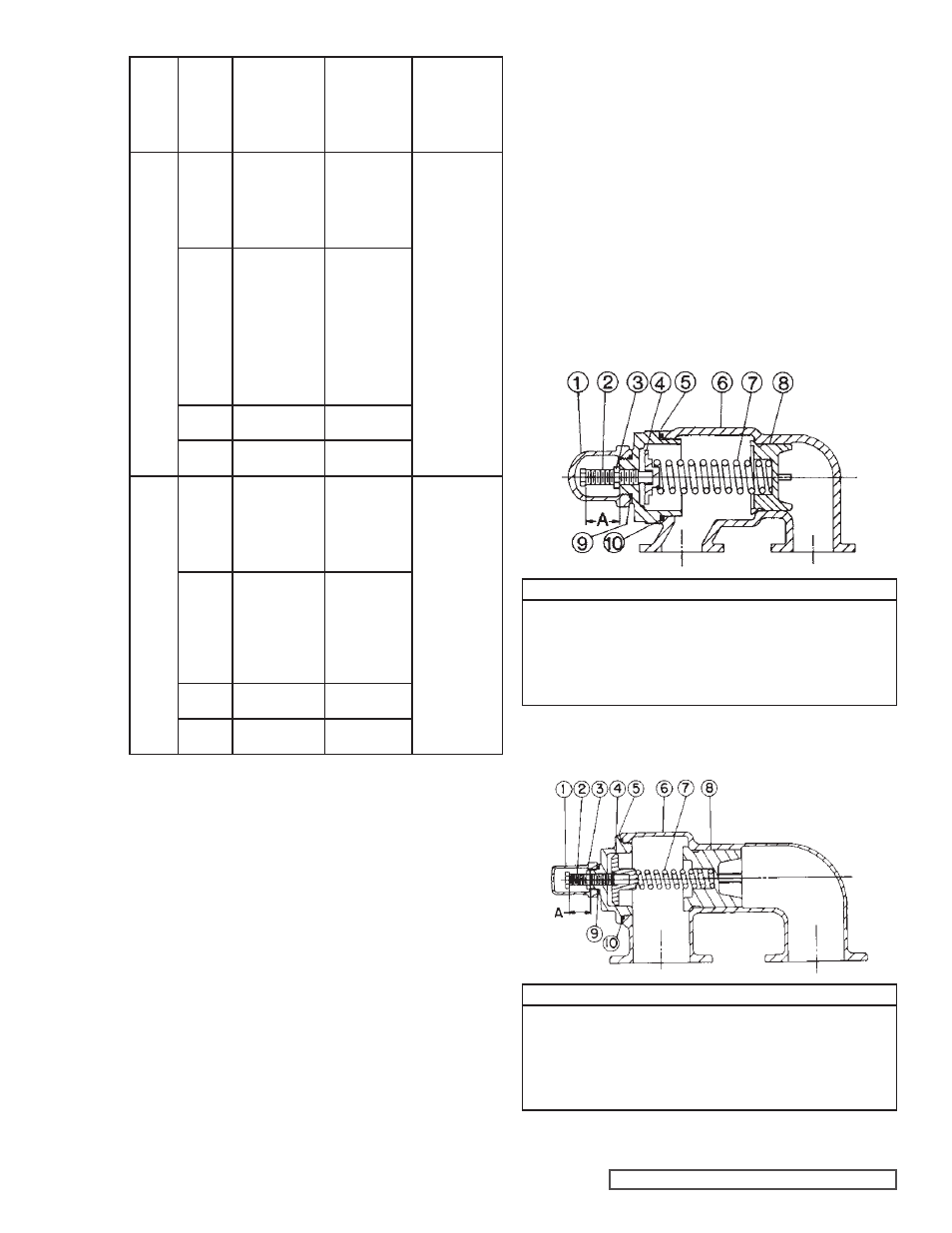

PRESSURE RELIEF VALVE

INSTRUCTIONS

VALVE - LIST OF PARTS

1. Valve Cap

6. Valve Body

2. Adjusting Screw

7. Valve Spring

3. Lock Nut

8. Poppet

4. Spring Guide

9. Cap Gasket

5. Bonnet

10. Bonnet Gasket

FIGURE 12

SIZE LS

Carbon graphite bushings with extra interference fits are

frequently furnished for high temperature operation. These

bushings must be installed by a shrink fit.

1. Heat bracket for idler to 750ºF.

2. Install cool bushing with a press.

3. If facilities are not available to reach 750ºF. temperature,

it is possible to install with 450ºF. temperature; however

the lower the temperature the greater the possibility of

cracking the bushing.

4. Consult factory with specific questions on high

temperature applications.

Refer to Engineering

Service Bulletin ESB-3.

VALVE - LIST OF PARTS

1. Valve Cap

6. Valve Body

2. Adjusting Screw

7. Valve Spring

3. Lock Nut

8. Poppet

4. Spring Guide

9. Cap Gasket

5. Bonnet

10. Bonnet Gasket

FIGURE 13

SIZES Q AND QS