Cartridge type, Danger – Viking Pump TSM630.2: LS-QS Universal Seal User Manual

Page 7

SECTION TSM 630.2

ISSUE

I

PAGE 7 OF 12

Elastomeric bellows and PTFE wedge seals generally require

pump disassembly to be replaced

(See Disassembly, steps

1-5, page 4).

1. Loosen nuts and remove seal plate, seal plate holder,

seal seat and seal gasket(s).

2. Loosen setscrew in set collar (bellows) or mechanical

seal rotary member (wedge).

NOTE: Piping and/or

plugs will need to be removed to access setscrews.

3. The remainder of the mechanical seal may be removed

in conjunction with Step 7 of

Disassembly, page 4.

ELASTOMERIC BELLOWS

AND PTFE WEDGE TYPE

SEAL INSTALLATION

COAT ROTOR SHAFT, TAPERED INSTALLATION

SLEEVE AND INNER DIAMETER OF MECHANICAL

SEAL WITH LIGHT OIL BEFORE ASSEMBLY.

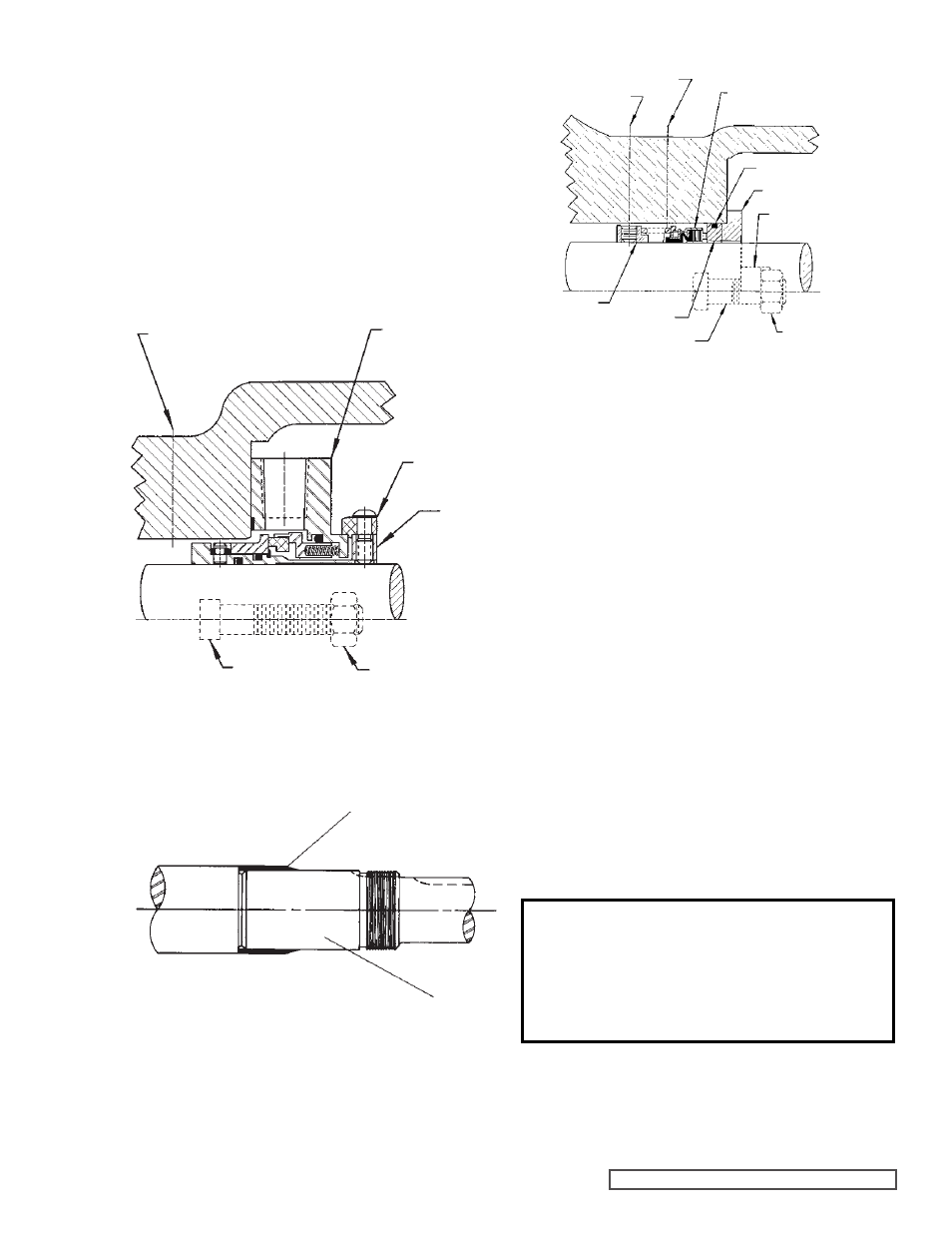

FIGURE 7

CARTRIDGE MECHANICAL SEAL

FIGURE 8

1. NOTE: Burrs left on shaft can damage O-ring on seal

sleeve during installation. Inspect shaft for burrs and

remove any found with a fine grade of emery cloth.

2. Clean rotor shaft and face of seal chamber.

3. Slide cartridge seal on shaft until it contacts the seal

chamber face.

4. Follow steps 9-12 on page 6 under Assembly.

5. Insert gland capscrews and secure gland to bracket face.

NOTE: Turn shaft several turns while gland is loose to

center seal; then tighten gland tight enough to compress

gasket. Tighten only enough to contain leakage and not

to distort gland.

6. Lock cartridge seal drive collar to shaft and remove or

turn centering clips out of the way so as to clear the drive

collar.

7. Turn shaft by hand or jog motor to check drive collar for

runout.

8. Connect circulation line or vent stuffing box seals without

line until liquid is present on start up.

NOTE: For maximum seal life, circulation line should be used.

CARTRIDGE TYPE

FIGURE 9

ELASTOMERIC BELLOWS SEAL

CIRCULATION LINE

CONNECTION

SEAL ACCESS

HOLE

MECHANICAL SEAL

(ROTARY MEMBER)

SEAT GASKET

SEAL HOLDER

(NOT USED ON LS)

SEAL PLATE

(PACKING GLAND

ON LS)

NUT

CAPSCREW

SEAL SEAT

SET COLLAR

ASSEMBLY

DANGER !

Before starting pump, be sure all drive

equipment guards are in place.

Failure to properly mount guards may

result in serious injury or death.

VENT CONNECTION

CARTRIDGE

MECHANICAL

SEAL

CENTER

CLIPS

SEAL

COLLAR

NUT

CAPSCREW

TAPERED INSTALLATION SLEEVE

Q, QS SIZES

SHAFT