Assembly, C” reducer assembly - see fig. 9 – Viking Pump TSM610: Offset Gear Reducers User Manual

Page 6

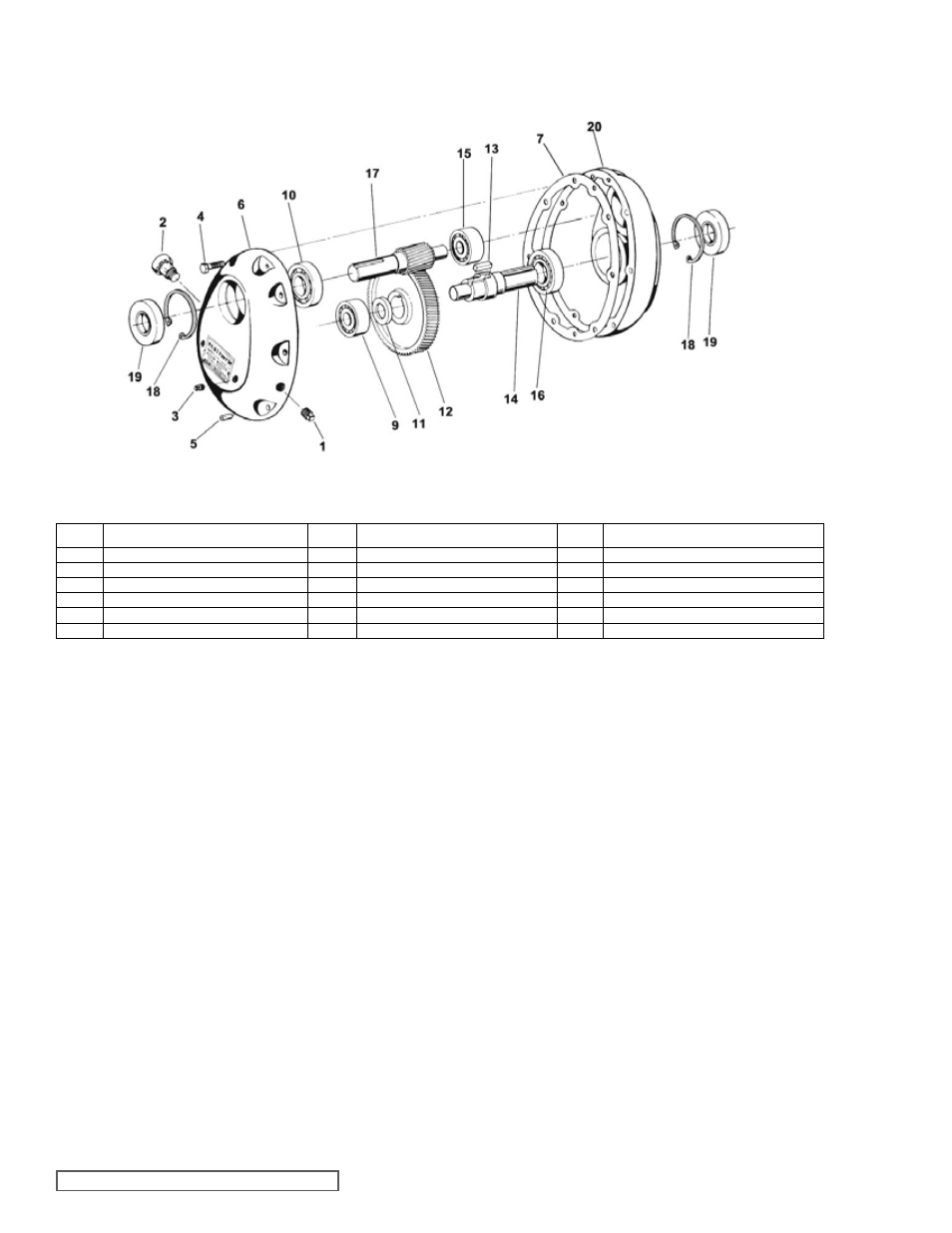

ITEM

NAME OF PART

ITEM

NAME OF PART

ITEM

NAME OF PART

1

Drain Plug

7

Gasket

14

Gear Shaft

2

Breather

9

Ball Bearing (Double Row)

15

Ball Bearing (Double Row)

3

Pipe Plug (Set-2)

10

Ball Bearing (Single Row)

16

Ball Bearing (Single Row)

4

Capscrew (Set-2)

11

Spacer

17

Pinion and Shaft

5

Dowel Pin Locating (Set-2)

12

Gear

18

Snap Ring (Set-2)

6

Gear Case Cover

13

Key

19

Lip Seal (Set-2)

SECTION TSM

610

ISSUE

G

PAGE 6 OF 8

1. Install the ball bearing on the pinion shaft; the double row

bearing on the small diameter end, and the single row

bearing on the large diameter end. Be sure the bearings

are seated firmly against the shoulders on the shaft.

NOTE: The pinion and shaft for “C” reducer (7.95 to 1

ratio) is furnished with a snap ring. This snap ring must

be installed in the groove on the shaft prior to bearing

assembly. The bearing should be seated against the snap

ring.

2. Install the square key in the gear shaft and press the gear

into place. Be sure the gear seats against the shoulder on

the shaft.

3. Place the spacer on the gear shaft with bevelled edge

toward the gear. Install the bearing over gear shaft and

seat firmly against the spacer. Install a second bearing

on large end of the gear shaft and seat the bearing firmly

against the shaft shoulder.

4. If the lip seals have been removed during disassembly

place gear case and cover, gaskets face down, on surface

which will not mar the face. Be sure the snap rings are in

the face and cover. Put gasket sealer on the O.D. of lip

seals. Drive new lip seals with lip toward the inside of the

reducer, in place against the snap rings. Use a wood block

covering entire lip seal and drive evenly. Apply lubricant to

lip seal surfaces.

5. Block the gear case, open side up, to provide at least

3¾” clearance between case and assembly bench.

6. Make certain the pinion and gear shaft keyways are free

of burrs and sharp edges to prevent damaging the lip seal

sealing surfaces. Take the pinion and gear assemblies,

mesh the gear teeth, and insert simultaneously into the

gear case half. Rotate the gear shaft slightly as it is

pushed through the lip seal. Tap the end of the pinion

shaft and gear shaft with hardwood block to seat the

bearings in the counter bores.

7. Place the gasket on gear case. If the gasket is damaged,

discard it and use a new gasket.

8. Align the gear case cover with the ends of the pinion

and gear shafts, and carefully push the cover into place.

Rotate the pinion shaft during assembly. Tap the cover

with a hardwood block to seat the bearings in cover.

9. Install the seven capscrews and nuts and tighten

securely, alternating around the gear case to prevent

distortion.

10. Install the drain plug. Be sure the reducer is filled with

proper lubricant. See “Lubrication” instructions, page 2.

ASSEMBLY

“C” Reducer Assembly - See Fig. 9

FIGURE 9

“C” SIzE hELICAL GEAR REDUCER - ExPLODED VIEW