Installation, Disassembly, Operation – Viking Pump TSM610: Offset Gear Reducers User Manual

Page 3: Gear ratios

SECTION TSM

610

ISSUE

G

PAGE 3 OF 8

INSTALLATION

Viking helical gear reducers are shipped completely

assembled and ready for installation except for the addition

of lubricant.

1. Fasten the pump securely to the baseplate.

2. Mount the reducer on the reducer bracket finger tight.

The breather cap should be located on the upper side of

the reducer and drain plug on the bottom.

3. Place the coupling halves on the high and low speed

reducer shafts.

4. Align the low speed shaft coupling half with the coupling

half on the pump or driver shaft. Use a straight edge to

align the coupling as in figure 6. A C-clamp, clamped over

pieces of keystock, may be used to hold this alignment

until the mounting bracket is securely bolted to the base

plate. It may be necessary to shim the bracket to the

extact center height of the pump or driven shaft. For

additional information on coupling alignment, refer to

Engineering Service Bulletin #ESB 61.

SIzE

RATIO

ChANGES REQUIRED

B

6.27 to 1

Snap ring for pinion and shaft

7.65 to 1

Two spacers ( A larger O.D. than is used

on other ratios) and gear shaft

C

7.95 to 1

Gear shaft and a longer key, also a snap

ring.

NOTE: SNAP RING IS FURNISHED WITH “C” 7.95 TO 1 PINION AND

SHAFT

When changing the reducer ratio, the nameplate should

also be changed to new ratio reducer part number. After

making any output or input speed change (complete reducer

or gear ratio changes), a check should be made to ensure

the couplings are of sufficient size for the conditions which

reducer will be operating. For ratios available see page 1 of

this manual, catalog specification sheet or consult factory or

Viking representative.

DISASSEMBLY

Before starting disassembly, study the exploded view (see

Fig. 7, 8 or 9) for the particular size reducer that is being

disassembled to help determine parts relationship. The parts

are indexed in a logical sequence of disassembly and will

prove to be a valuable aid in dismantling the reducer.

1. Disconnect the couplings and remove the capscrews

holding the mounting bracket to the base. Remove the

coupling halves and bracket from the reducer.

2. Remove the breather and drain plugs. Drain all lubricant

from the reducer.

3. Remove the capscrews from the gear case halves.

4. Tap firmly and alternately on the gear shaft and pinion

shaft. This will separate the reducer halves.

5. With two screwdrivers at opposite sides, carefully pry

the reducer cover loose from internal ball bearings. DO

NOT FORCE. Be careful not to damage the gasket or

gasket surface.

6. Grasp the pinion and gear shafts and pull both

assemblies simultaneously from the case or cover.

7. Use a conventional gear or bearing puller to remover the

bearing from gear shaft. Remove the bevelled spacer on

“B” and “C” size reducers. Press the shaft from the gear.

8. Use a puller and remove bearings from the pinion shaft.

Remove the spacer from “B” size 7.65 to 1 ratio from the

pinion shaft.

9. Remove the lip seals from the gear case halves (cover

and case) only if they show signs of deterioration or

damage. Lip seals must be pressed or driven out

from the inside of gear case and cover on “B” and “C”

reducers. “A” size reducer may have lip seals pressed in

or out from either side of gear case half.

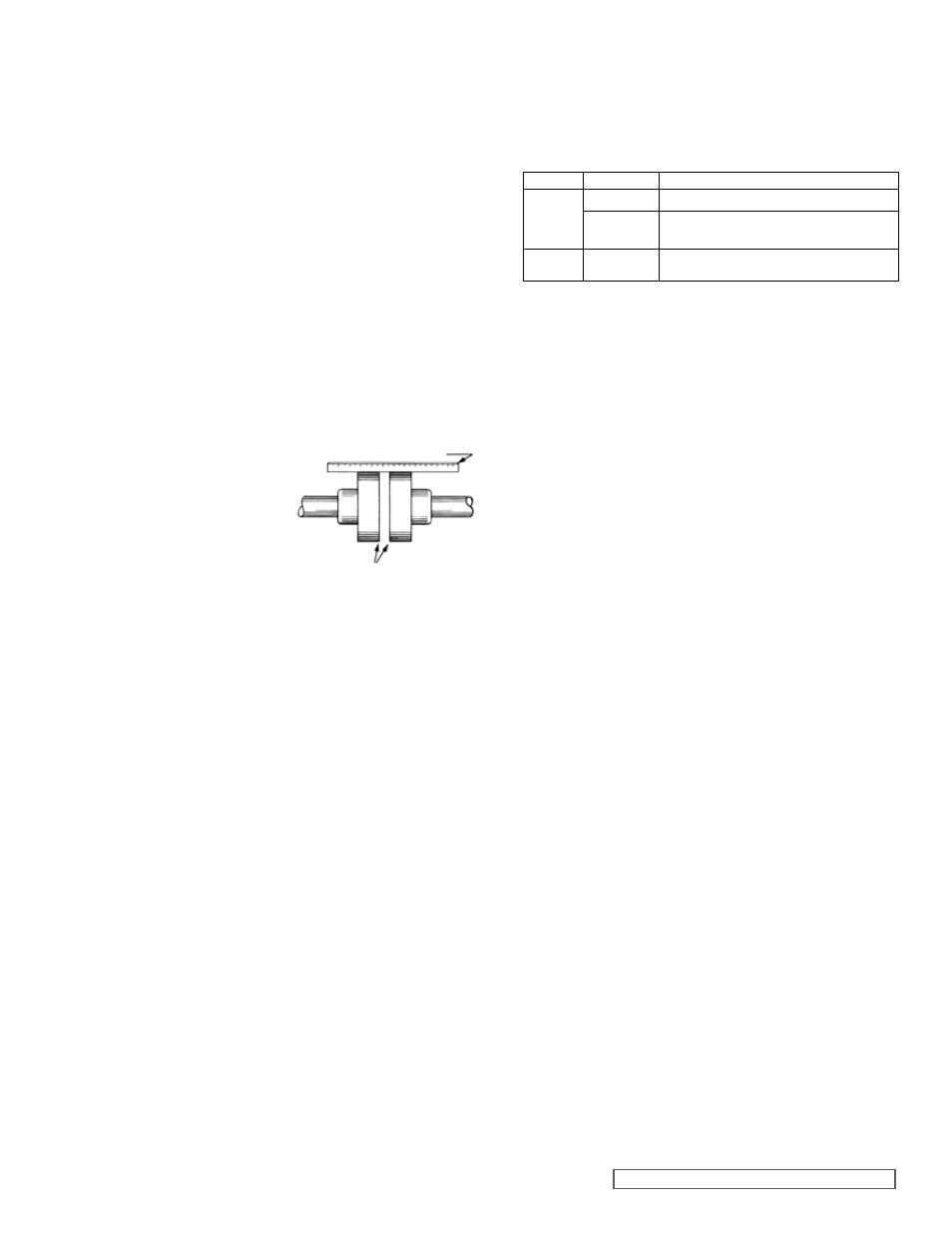

FIGURE 6

COUPLING ALIGNMENT

USE STRAIGHT EDGE. THESE SURFACES MUST BE PARALLEL

CHECK WIDTH BETWEEN THESE SURFACES WITH INSIDE CALIPERS TO BE

CERTAIN THE FACES ARE EQUAL DISTANCE APART AND PARALLEL

5. Rotate the reducer in the “banana” slots of the bracket

until the high speed coupling half is at the exact center

height of the motor coupling half.

6. Securely tighten the reducer to the bracket .

7. Align the high speed shaft coupling and fasten the motor

securely to base plate.

CAUTION ! : DO NOT EXCEED RECOMMENDED MAXIMUM

HORSEPOWER, SEE CATALOG SPECIFICATION SHEET.

DO NOT OPERATE BEFORE ADDING LUBRICANT.

OPERATION

After the first few hours of operation, inspect reducer for

leaks. If leakage between gear case and cover cannot be

stopped by tightening of nuts or capscrews, the gasket

should be replaced. Leakage around either shaft indicates a

damaged lip seal which should be replaced.

The operating temperature on the outside of the reducer

case, after a few hours operation, should not be more than

approximately 75º F higher than surrounding air temperature.

The oil within the Reducer should never exceed 200º F.

Gear Ratios

Four different gear ratios are available for the “A” size

Reducers. Eight ratios are available for “B” size reducers and

seven ratios for “C” size reducers. Complete reducers within

a size may be interchanged on a Viking pump unit to obtain

desired pump speeds and capacities.

Gear ratios may be changed in all reducers within each size

by selecting the proper pinion and gear of a common ratio.

A pinion from one ratio cannot be used with a gear from a

different ratio. Certain “B” and “C” reducers require additional

or different parts besides the pinion and gear to make the

ratio change. See the chart below for changes required.