Maintenance, Special information (cont’d) – Viking Pump TSM344: CMD Mag Drive User Manual

Page 3

SECTION TSM 344

ISSUE

F

PAGE 3 OF 24

MAINTENANCE

DANGER !

Before opening any viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been

“locked out” or made non-operational

so that it cannot be started while

work is being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

Failure to follow above listed

precautionary measures may result in

serious injury or death.

Series CMD pumps are designed for long, trouble-free

service life under a wide variety of application conditions with

a minimum of maintenance. The following points will help

provide long service life.

Pumps that are mounted directly to the motor will need to be

removed from the mounting bracket to perform mechanical

seal maintenance or replacement.

CLEANING PUMP: Keep the pump as clean as possible.

This will facilitate inspection, adjustment, and repair work.

STORAGE: If pump is to be stored, or not used for six

months or more, the pump must be drained and a light coat

of light oil must be applied to all internal pump parts.

Apply grease to the pump shaft extension. Viking suggests

rotating pump shaft by hand one complete revolution every

30 days to circulate the oil. Tighten all pump assembly bolts

before putting the pump in service after being stored.

PRESSURE RELIEF VALVES:

1. Viking pumps are positive displacement pumps and

must be provided with some sort of pressure protection.

This may be an inline pressure relief valve, a torque-

limiting device, or a rupture disk, or other method.

NOTE: Pump can be operated in reverse direction for

short duration at low differential pressure to clean/flush

out lines.

2. If pump rotation is to be reversed during operation,

pressure protection must be provided on both sides

of the pump.

3. Pressure relief valves cannot be used to control pump

flow or regulate discharge pressure.

For additional information on pressure relief valves,

refer

to Technical Service Manual TSM000 and Engineering

Service Bulletin ESB-31.

SPECIAL INFORMATION (CONT’D)

Viton

®

is a registered trademark of DuPont Performance Elastomers.

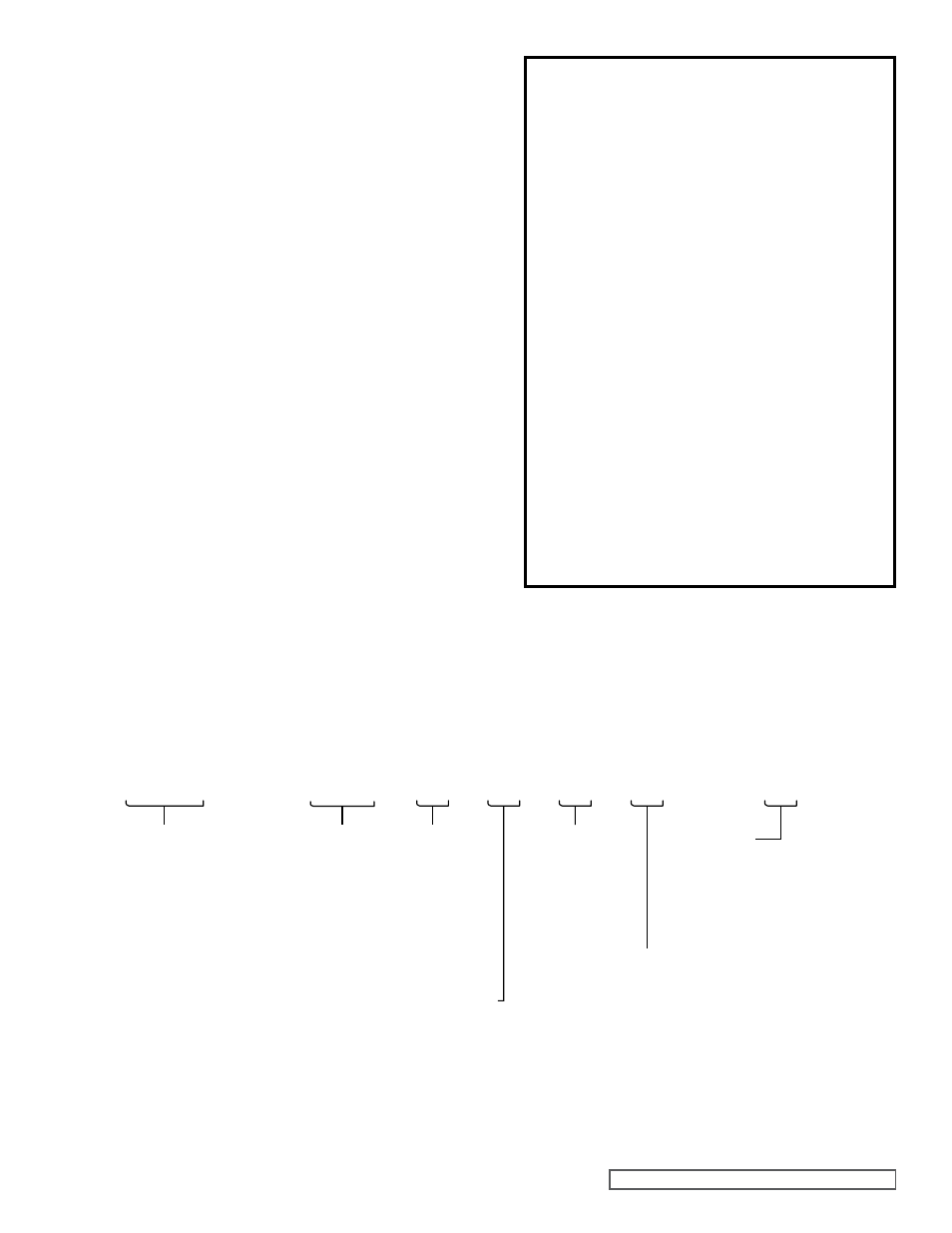

CMD - E02 E L v F - X

Mounting Arrangement:

F = NEMA 56C (E02, E05, E12, E25)

O = NEMA 143TC-182C (E05, E12, E25, E75, E125)

R = NEMA 182TC-184TC (E75, E125)

H = IEC B34 63 (E02, E05, E12)

K = IEC B34 80 (E02, E05, E12)

P = IEC B14 100/112 (E25, E75, E125)

Y = No Motor Mount Kit (E02, E05, E12, E25, E75, E125)

Model:

E02

E05

E12 *

E25 *

E75 *

E125 *

Series:

Composite Mag Drive

Materials/Ports:

E = ETFE, FNPT

(E02, E05, E12)

B = ETFE, ISO 7-1

(E02, E05, E12)

F = ETFE, Flange

(E25, E75, E125)

Bearings:

L = Carbon Graphite

B = Graphite-Impregnated

Silicon-Carbide

O-Rings:

V = Viton

®

E = EPDM

Options:

A = Bearing Flush Ports

B = Combination of Options A and N

N = Without Drive Magnet

X = Complete Pump (No Options)

* Export license required under U.S. Export

Administration ECCN 28350 and 28999.