Normal operation expected malfunction – Viking Pump TSM344: CMD Mag Drive User Manual

Page 23

SECTION TSM 344

ISSUE

F

PAGE 23 OF 24

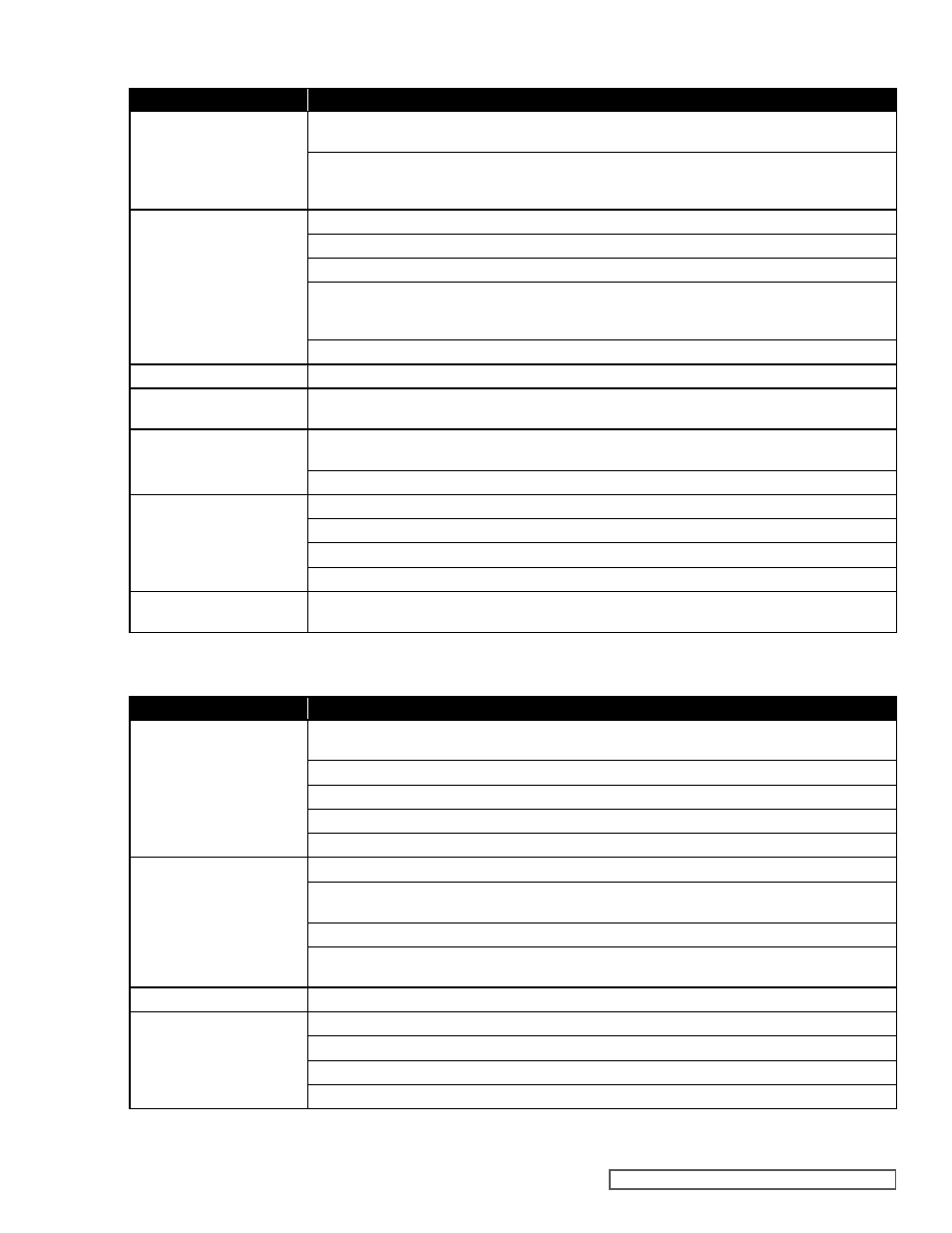

Potential Ignition Source Measures to take to prevent the source from becoming effective

Frictional ignition

All moving parts in the pumps are submersed in the pumped fluid, which acts as a lubricant

and coolant. Do not run the pump dry.

Packing is not recommended for Explosive environments due to the possibility of high

temperature in the area of the stuffing box due to mis-adjustment. If packing is used, thermal

monitoring is required to meet ATEX requirements.

Pump bearings

Verify pump turns freely.

The use of a strainer is recommended.

The use of bearing flushing is recommended.

The bearing housings need to be examined for signs of overheating, abnormal noise, or

discoloration on a daily basis. Alternatively continuous temperature monitoring can be fitted

and set to trip the drive power at 10 C above normal baseline temperature.

Monitor pump frequently when pumping non-lubricating fluids.

Power frame bearings

Check lubricant level weekly and monitor for leaks daily.

Dust deposits on pump

Regular cleaning is needed to prevent deposits from accumulating in a thickness great

enough to become an ignition hazard.

Static electricity

discharge

The pump must be grounded (bonded) at the “Protective Earth Ground” location marked on

the pump.

Vent cavities to prevent Oxygen / Air build up.

high temperatures

Recommend Temperature monitors.

Recommend Flow indicator.

Recommend Power monitor.

Recommend Pressure switch.

Use of electric motor

If an electric motor is used as a driver for the pump, it must be ATEX approved for the

environment.

Potential Ignition Source Measures to take to prevent the source from becoming effective

Dry run

All moving parts in the pumps are submersed in the pumped fluid, which acts as a lubricant

and coolant. Do not run the pump dry.

Recommend Power monitor.

Recommend Flow indicator.

Recommend Pressure switch.

Recommend Temperature monitors.

Pump bearings

Max. radial wear on bearings is .13 mm (.005 in).

Monitor pump daily when pumping non-lubricating fluids for high temperatures at bearing

bosses.

Every 1000 hours inspect the pump for wear and rebuild with a repair kit if necessary.

Typical life of the pump bearings is 2000 hours. Regular maintenance and good record

keeping will provide a more accurate service interval.

Power frame bearings

Check condition of lip seals for the power frame every month to insure lubricant containment.

high temperature

Recommend Temperature monitors.

Recommend Flow indicator.

Recommend Pressure switch.

Recommend Power monitor.

NORMAL OPERATION

EXPECTED MALFUNCTION