Viking Pump TSM344: CMD Mag Drive User Manual

Page 14

SECTION TSM 344

ISSUE

F

PAGE 14 OF 24

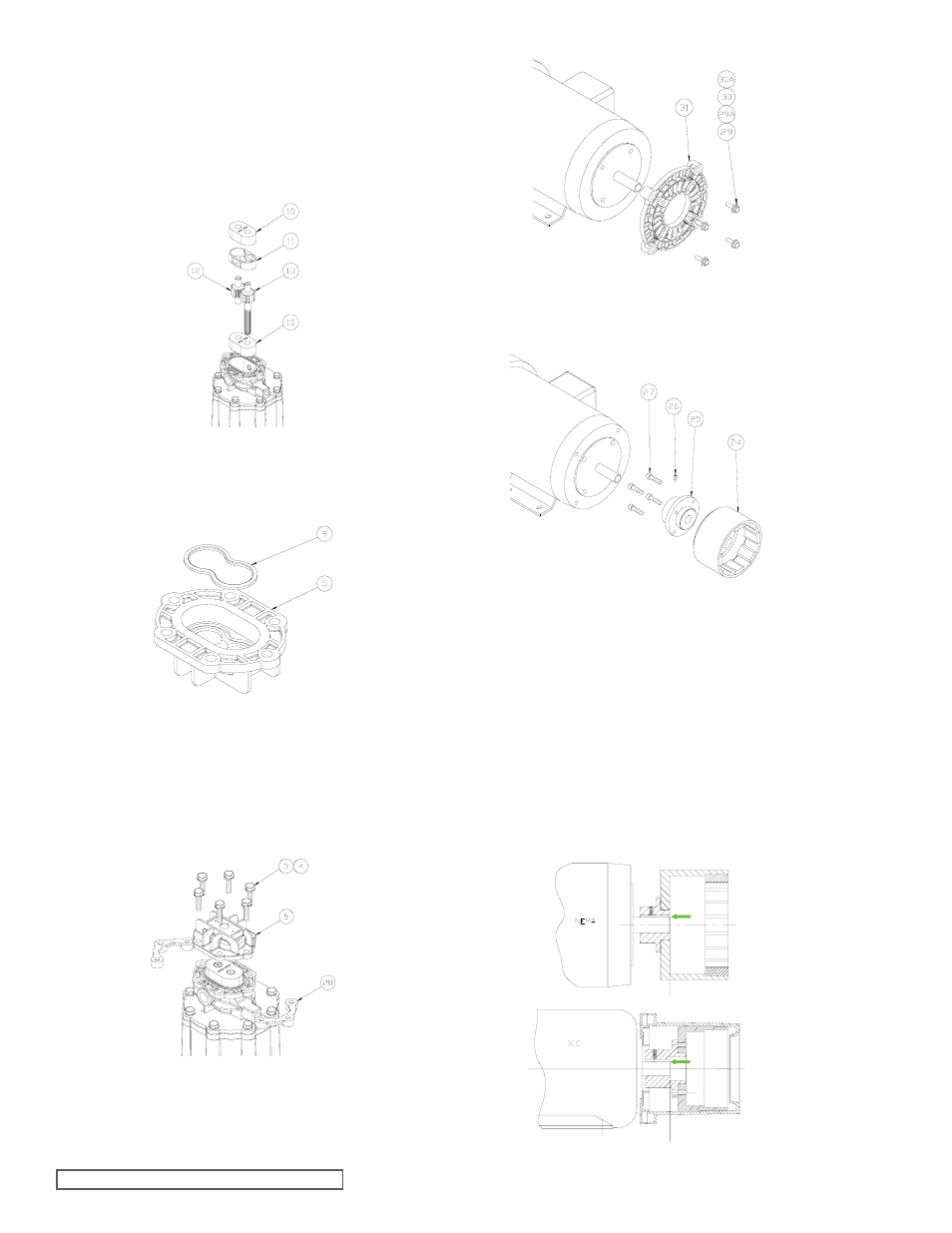

9. Install the spacer O-Ring (item 9) into the front cover

(item 5) as shown. Some O-Ring lubricant may help

keep the O-Rings in place during assembly.

10. Place the front cover (item 5) with O-Ring onto the

assembled pump. Secure the front cover using the

six bolts and washers (items 3, 4) and two nut plates

(item 28) as shown. The flat side of the nut plates mate

against the back of the center housing flange. Tighten

these bolts to the torque specified on

page 20. Always

tighten fasteners in a progressive “crisscross” pattern.

11. For IEC frame motors only, if it was removed, install the

motor adaptor plate (item 31) onto the motor face using

the four bolts and washers (items 29 and 30). Always

tighten fasteners in a progressive “crisscross” pattern.

12. Secure the magnet hub (item 25) to the drive magnet

(item 24) using the four screws (item 27). Always tighten

fasteners in a progressive “crisscross” pattern.

13. Inspect and remove any debris or foreign materials that

may have attached to the magnet.

Align the keyway, and slide the drive magnet onto the

motor shaft until the end of the motor shaft aligns with

faces of the drive magnet motor hub as shown below.

Secure with the setscrew (item 26). Application of a no-

seize compound on the shaft and key will make future

maintenance easier.

14. Complete the assembly by replacing the assembled

pump onto the motor, using care not to allow fingers

to get pinched when the magnets attract. Secure the

pump to the motor with the four bolts and washers

(items 22, 23). Always tighten fasteners in a progressive

“crisscross” pattern.

FIGURE 29

FIGURE 30

FIGURE 31

FIGURE 32

FIGURE 33

7. Install the drive gear (item 13), splined-end first, into the

assembly until it bottoms out against the bearing. The

shaft may have to be rotated slightly to properly fit the

splined-end into the drive magnet and mesh gear teeth

with the idler gear.

8. Insert the second bearing (item 10) into the housing

bore until it rests against the housing liner. Bearings are

symmetrical and orientation does not matter.

FIGURE 28