Caution – Viking Pump TSM320.2: GG-HL 75/475 User Manual

Page 5

SECTION TSM 320.2

ISSUE

F

PAGE 5 OF 9

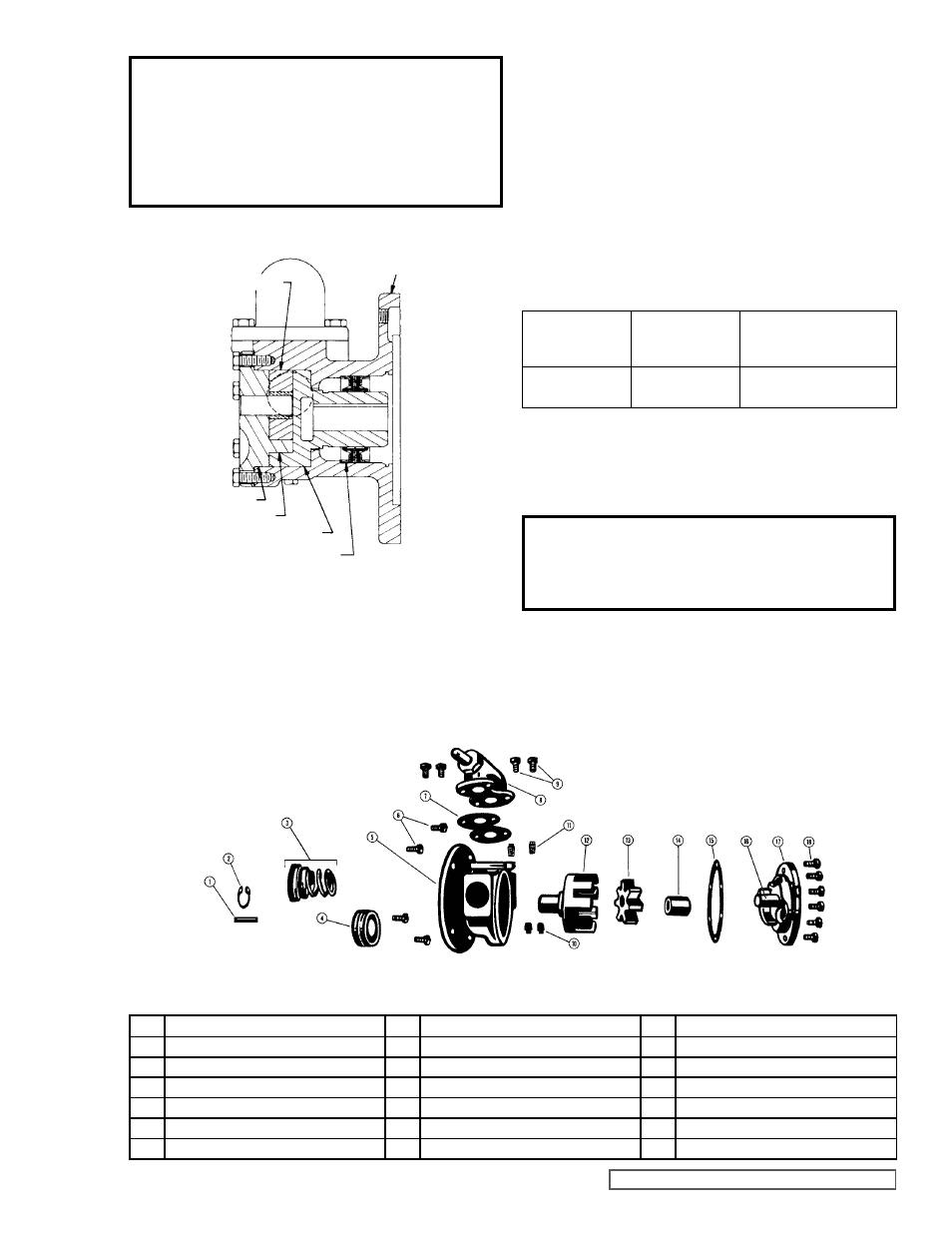

FIGURE 6

EXPLODED VIEW SERIES 75 & 475 PUMPS (G AND GG SIZE)

ITEM

NAME OF PART

ITEM

NAME OF PART

ITEM

NAME OF PART

1

Key for Motor Shaft (Full Length)

7

Gasket for Relief Valve or Cover Plate

13

Idler

2

Snap Ring (Mech. Seal Pumps Only)

8

Relief Valve

14

Idler Bushings

3

Mechanical Seal (Complete)

9

Capscrews for Relief Valve or Cover Plate

15

Gasket for Head

4

Lip Seal (2)

10

Pipe Plugs - 1/8”

16

Idler Pin

5

Casing

11

Machine Screw (2-Mech. Seal, 1-Lip Seal)

17

Head

6

Capscrews (Pump on Motor)

12

Rotor

18

Capscrews for Head

CAUTION !

Turn the rotor back and fourth as you

exert enough force to push it through the

lip seal and to the bottom of the casing.

Be careful not to fold under the lip of the

inner seal.

FIGURE 5

SECTIONAL DRAWING OF MODELS G75 & GG75

LIP SEAL PUMPS

MOUNTING FLANGE

IDLER

HEAD

CRESCENT

ROTOR

LIP SEALS (2)

4. INSTALL THE IDLER. Put the idler with the bushings on

the idler pin.

CAUTION !

Be sure the adjusting screw of the relief

valve points toward the suction port.

PUMP

MODELS

NORMAL

AMOUNT USED

(INCH)

ONE SET OF GASKETS

CONSISTS OF THE

FOLLOWING

G75 and GG75

Lip Seal Pumps

.010” - .015”

2 - .005” Plastic

3 - .002” Plastic

GASKET TABLE 1

6. THE HEAD CAN NOW BE ASSEMBLED ON THE

PUMP. Tilt the top of the head away from the pump

slightly until the crescent enters the inside diameter of

the rotor and rotate the idler until its teeth mesh with

the rotor teeth. Do not damage the head gaskets. Note

correct position of the idler and crescent

(See Figure 5

and

Disassembly step 2). Tighten the head capscrews

and then check the end clearance.

7. CHECK PUMP END CLEARANCE. Measure the

clearance between the back of the rotor and the

mechanical surface in the bottom of the casing by

inserting a feeler gauge through the port opening. This is

the end clearance; the normal amount is 0.003” to 0.005”.

Add or remove gaskets until the figure is reached.

8. BOLT THE VALVE INTO THE CASING. Place the valve

gasket and valve or cover-plate on the pump and fasten

securely with the four capscrews.

5. PLACE HEAD GASKETS ON THE PUMP HEAD. The

proper amount of gaskets should be used to provide

necessary end clearance within the pump so it turns

freely with no appreciable end play.

Gasket Table 1

gives the normal amount of gaskets used.

9. ASSEMBLE THE PUMP ON THE MOTOR. Install the

full length key in the keyway of the motor shaft.

NOTE: Key must be full length to avoid misalignment of

the pump rotor, which could cause serious damage to

the pump. Slide the pump on the motor shaft and fasten

securely with the four capscrews.