Maintenance – Viking Pump TSM320.2: GG-HL 75/475 User Manual

Page 3

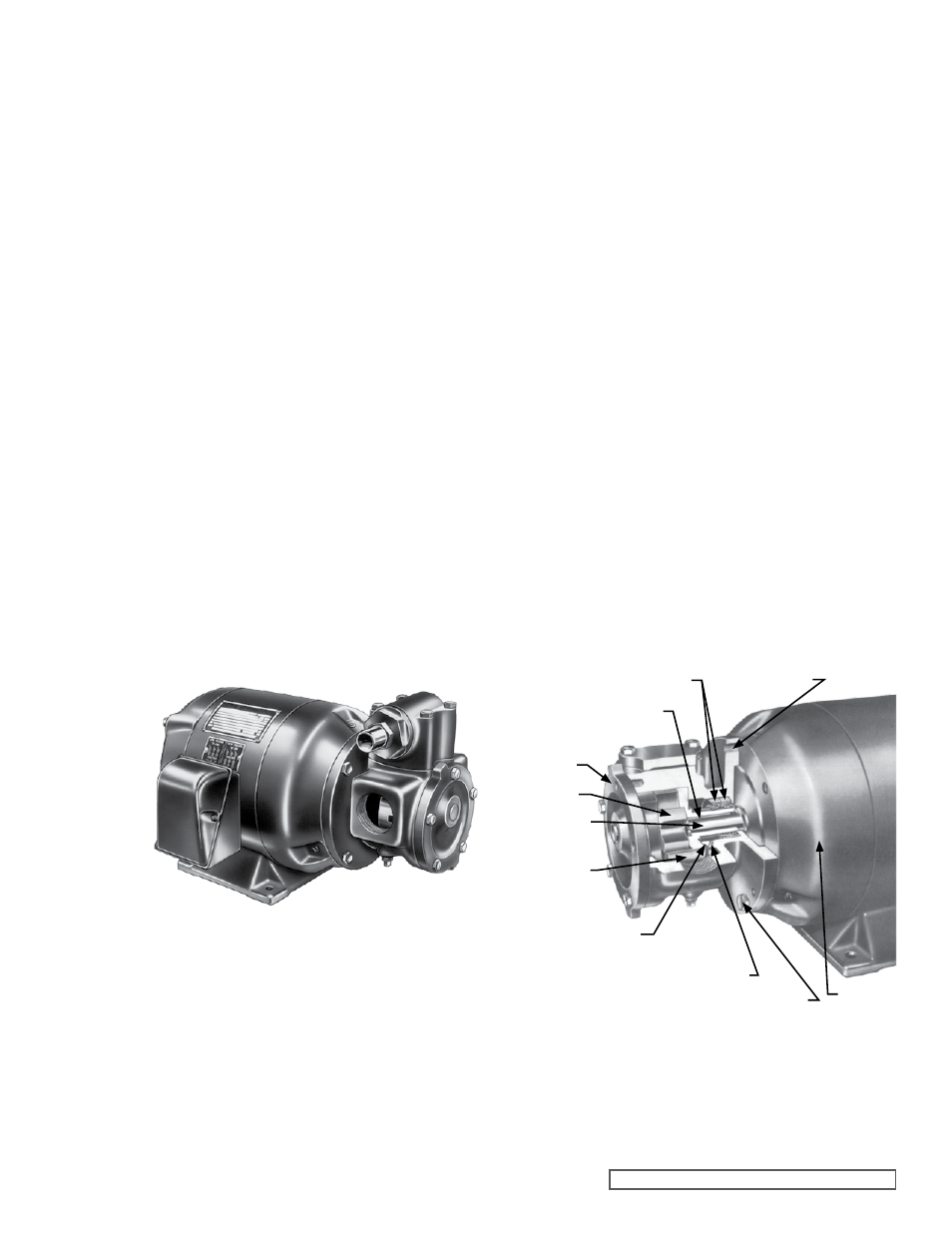

FIGURE 3

CUTAWAY OF H, HJ AND HL 75

LIP SEAL PUMPS

ROTOR

MOTOR KEY

CHECK END

CLEARANCE

MOUNTING

CAPSCREW

JACKSCREW

HOLE

LIP SEALS (2)

SUCKBACK SCREW

MOTOR

HEAD

IDLER

MOTOR

SHAFT

SECTION TSM 320.2

ISSUE

F

PAGE 3 OF 9

PRESSURE RELIEF VALVES:

1. Viking pumps are positive displacement pumps and

must be provided with some sort of pressure protection.

This may be a relief valve mounted directly on the pump,

an inline pressure relief valve, a torque limiting device or

a rupture disk.

2. This series of pumps may be equipped with an integral

pressure relief valve. Standard configuration is for

clockwise rotation.

3. If pump rotation is reversed during operation, pressure

protection must be provided on

both sides of the pump.

4. Relief valve adjusting screw cap must always point

towards the suction side of the pump.

5. Pressure relief valves should not be used to control

pump flow or regulate discharge pressure.

For additional information on pressure relief valves,

Refer

to Technical Service Manual TSM000 and Engineering

Service Bulletin ESB-31.

NOTE: Lip seal pumps, Models G75, GG75, H75, HJ75,

HL75, G75M, GG75M, H75M, HJ75M and HL75M are

equipped with an internal suckback arrangement. A small

suckback screw (self-locking) is inserted in a hole on the

discharge side of the pump. This can be seen through

the port opening and behind the rotor

(refer to figure 3).

The hole on the suction side must be left open to prevent

damage to the lip seals. Both holes are plugged in the

mechanical seal pump Model G475, GG475, H475, HJ465,

HL475, G475M, GG475M, H475M, HJ475M, and HL475M.

Since these pumps have only two moving parts and are

all performance tested at the factory, they seldom cause

trouble. If trouble does occur we always advise investigating

all other possible causes before disassembling the pump.

Most troubles are caused by air leaks and obstruction in

the suction line.

MAINTENANCE

The Series 75 and 475 pumps are designed for long trouble

free life under a wide variety of application conditions with

minimum maintenance, however, the following should be

considered:

1. LUBRICATION – External lubrication is not required for

this series of pumps. The liquid being pumped lubricates

the internal bearings in the pump.

FIGURE 2

MOTOR MOUNTED PUMP SHOWING

H, HJ AND HL SIZE

2. END CLEARANCE ADJUSTMENT – After long term

operation it is sometimes possible to improve the

performance of the pump, without major repair, by

adjusting the end clearance.

Refer to ASSEMBLY, page

4, for information regarding this procedure.

3. PRESSURE RELIEF VALVE – If your pump is equipped

with a pressure relief valve, adjustment can be made

as follows. Remove the adjusting screw cap, turn in the

adjusting screw to increase the pressure and turn-out to

decrease the pressure. If the pump is not producing the

rated capacity, adjustment of the pressure relief valve

may be necessary. Be sure the adjusting screw cap is

re-installed before the pump is started.

4. CLEANING THE PUMP – It is good practice to keep the

pump as clean as possible. This will facilitate inspection,

adjustment and repair work.

5. STORAGE – If the pump is to be stored or not used for

any appreciable length of time it should be drained and

a light coat of lubricating and preservative oil should be

applied to the internal parts

SUGGESTED REPAIR TOOLS: The following tools must be

available to properly repair Series 75 and 475 pumps. These

tools are in addition to standard mechanics’ tools such as

open end wrenches, pliers, screw drivers, etc. Most of the

items can be obtained from an industrial supply house.

1. Soft headed hammer

2. Allen wrenches (some mechanical seals and set collars)

3. Mechanical seal installation sleeve

4. Brass bar

5. Arbor press