Assembly disassembly – Viking Pump TSM320.2: GG-HL 75/475 User Manual

Page 4

SECTION TSM 320.2

ISSUE

F

PAGE 4 OF 9

1. REMOVE THE PUMP FROM THE MOTOR. Remove

the four capscrews and use three as jackscrews in the

threaded holes of the pump from the motor shaft.

NOTE: If the pump has a valve, it must be removed first

to have room for the jackscrews.

2. REMOVE PUMP HEAD.

NOTE: Mark the head and casing before disassembly

to make sure they are reassembled properly. The idler

pin, which is offset in the pump head, should be properly

positioned toward and equal distance between the port

connections to allow for proper flow of liquid through the

pump.

If it is necessary to disassemble the pump for inspection

or repair, first remove the head capscrews and remove

head by tapping the head removing lugs lightly.

3. REMOVE THE HEAD GASKETS. If a new set is not

available, the original gaskets may be reused provided

they are not damaged.

4. REMOVE THE IDLER FROM THE IDLER PIN. If the

idler pin is worn, the head, idler pin and idler bushing

should all be replaced.

If the idler bushing is worn, a new bushing is needed.

If the new bushing is carbon graphite, special care must

be taken when pressing it into the idler. An arbor press

should always be used; be sure the bushing is started

straight.

DO NOT STOP the pressing operation until

the bushing is in its proper location. Carbon graphite

is brittle; starting and stopping the pressing operation

Reassembly of these pumps is explained by one of the

following sets of instructions. Follow the instructions for the

proper pump model.

Before starting to reassemble the pump, clean all parts

thoroughly and replace those which show signs of excessive

wear or damage.

ASSEMBLY

DISASSEMBLY

DANGER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been “locked

out” or made non-operational so that

it cannot be started while work is

being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

Failure to follow above listed

precautionary measures may result in

serious injury or death.

To Reassemble Model G75 or GG75

Lip Seal Pumps: see Figure 5)

1. INSTALL THE LIP SEALS. The lip seals should be

installed in the casing one at a time from the large

flanged end. The sealing lips must face away from each

other.

NOTE: Use an arbor press with an arbor of 2.188

diameter and press the lip seals in the casing as far

as they will go.

See figures 7, 8, 9, and 10 for a cross

section of your pump models.

2. LUBRICATE THE LIP SEALS. Fill the area between the

lips of the lip seals with grease.

3. INSTALL THE ROTOR. Flush the rotor hub with light oil

(not grease) and insert the rotor in the casing with the

hub through the lip seals.

frequently results in a cracked bushing. If cracked in the

idler, the bushing will quickly disintegrate.

5. REMOVE THE ROTOR FROM THE CASING. The rotor

of the two smaller pumps (G & GG sizes) can be removed

by pressing on the end of hollow drive end of the rotor. It

will be necessary on the models with mechanical seals

(G475 & GG475) to use an arbor press and an arbor of

approximately 1.375” diameter. The seal will remain in

the casing.

The rotor of the three larger size pumps (H, HJ, HL

sizes) can also be removed by pushing on the hollow

drive end of the rotor. The spring and rotary member of

the mechanical seal will come out with the rotor in these

pumps.

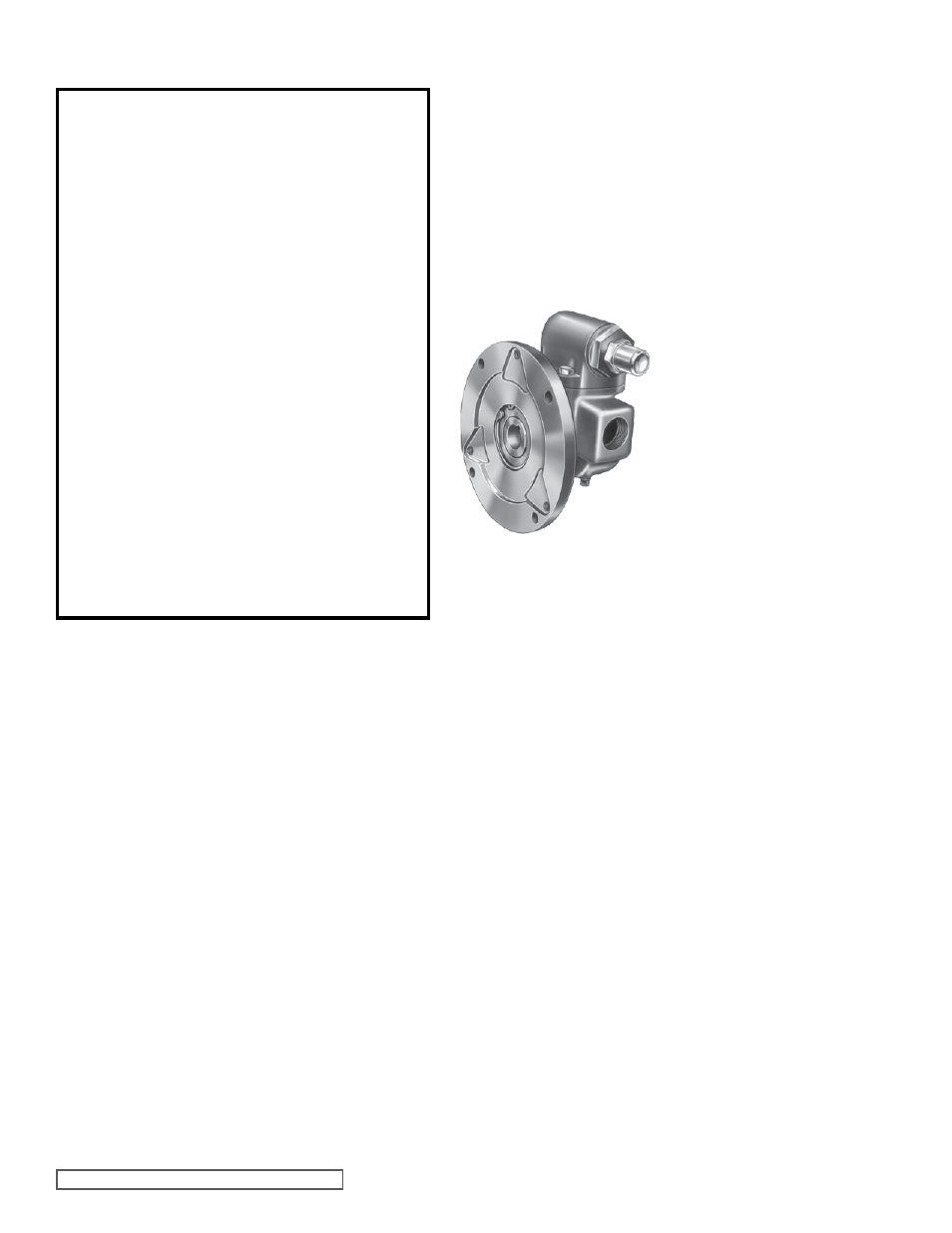

FIGURE 4

VIEW OF FLANGE END

OF G AND GG475

MECHANICAL SEAL PUMPS

6. REMOVE THE MECHANICAL SEAL OR LIP SEALS.

(See figure 4) Remove the snap ring in the casing of the

two smaller pumps (G and GG sizes) and the complete

seal can be removed out of the large flanged end of the

casing.

Remove the spring and rotary member from the rotor

and the seal seat or lip seals from the pump end of the

casing of the three larger size pumps (H, HJ, HL).