Installation of peek bushings – Viking Pump TSM270.2: RL 16 and 25 High Pressure User Manual

Page 9

SECTION TSM

270.2

ISSUE

A

PAGE 8 OF 12

SECTION TSM

270.2

ISSUE

A

PAGE 9 OF 12

check the arrows again to make sure they are positioned

as shown in Figure 9.

9. Remove the pump head.

10.Adjust the bearing housing assembly to position the

lobes slightly extended (approximately 1/8 inch )beyond

the front face of the casing. Place a wooden block or

brass bar in between the lobes to block rotation. Install

lockwashers and locknuts and tighten with the spanner

wrench. Locknuts must be tightened to 200 ft-lbs torque.

This torque is required to obtain the proper bearing

preload and ensure the bearing/timing gear assembly

is locked securely on the shaft. This torque can be

simulated by applying approximately 200 pounds of

weight with a one foot wrench or 100 pounds of weight

with a two foot wrench.

11. Set the end clearance; refer to End Clearance

Adjustment on page 8.

12. Inspect the lipseal in the gear case and replace if needed.

Put the o-ring in place, then install the gear case by

visually centering the lipseal over the shaft. Install the

capscrews, and torque evenly. Fill with gear oil to the

bottom of the fill hole, approximately 15 ounces.

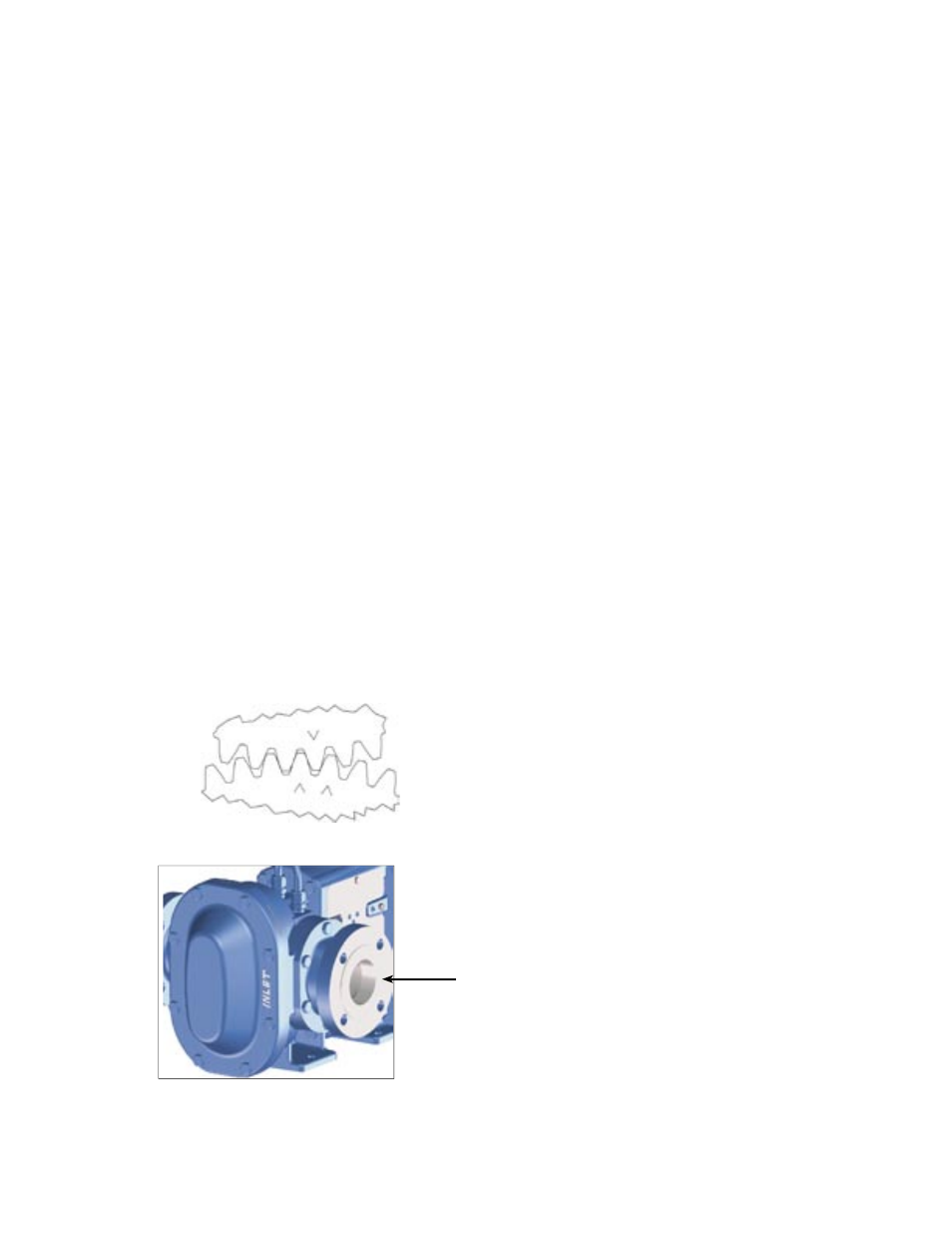

13. Place the o-ring and reinstall the head. The word INLET

cast into the head must be placed on the suction port side

of the pump (Figure 10). Torque the head capscrews per

Table 2.

14. Tighten the setscrews in each seal.

15. Replace the coverplate.

FIGURE 9

FIGURE 10

INLET PORT

*

PEEK

®

is a trademark of Victrex PLC

Installation Of Peek Bushings*

When installing the bushings, extreme care must be taken

to prevent breaking. The additional precautions listed below

must be followed for proper installation:

• A press must be used for installation.

• Use Loctite® #4203 or #411 on the outside of the bushing

to hold the bushing in the housing.

• Be certain that the bushing is straight. The groove in the

bushing should line up with the groove in the casing.

• Do not stop the pressing operation until the bushing is in

the proper position; starting and stopping may result in a

cracked bushing.

• Check the bushing for damage after installation.

Loctite® is a trademark of Henkel Consumer Adhesives, Inc.