Mechanical seal information, Optional cartridge lipseal seal replacement, Danger – Viking Pump TSM270.2: RL 16 and 25 High Pressure User Manual

Page 5: Cartridge mechanical seal replacement

SECTION TSM

270.2

ISSUE

A

PAGE 4 OF 12

SECTION TSM

270.2

ISSUE

A

PAGE 5 OF 12

The Industrial Lobe series pump can be supplied with a

variety of mechanical sealing configurations and materials.

The cartridge mechanical seal is considered standard

construction.

General installation and replacement instructions for

the optional lipseal and packing are provided. It is also

recommended to review the seal manufacture’s instructions

for a specific seal.

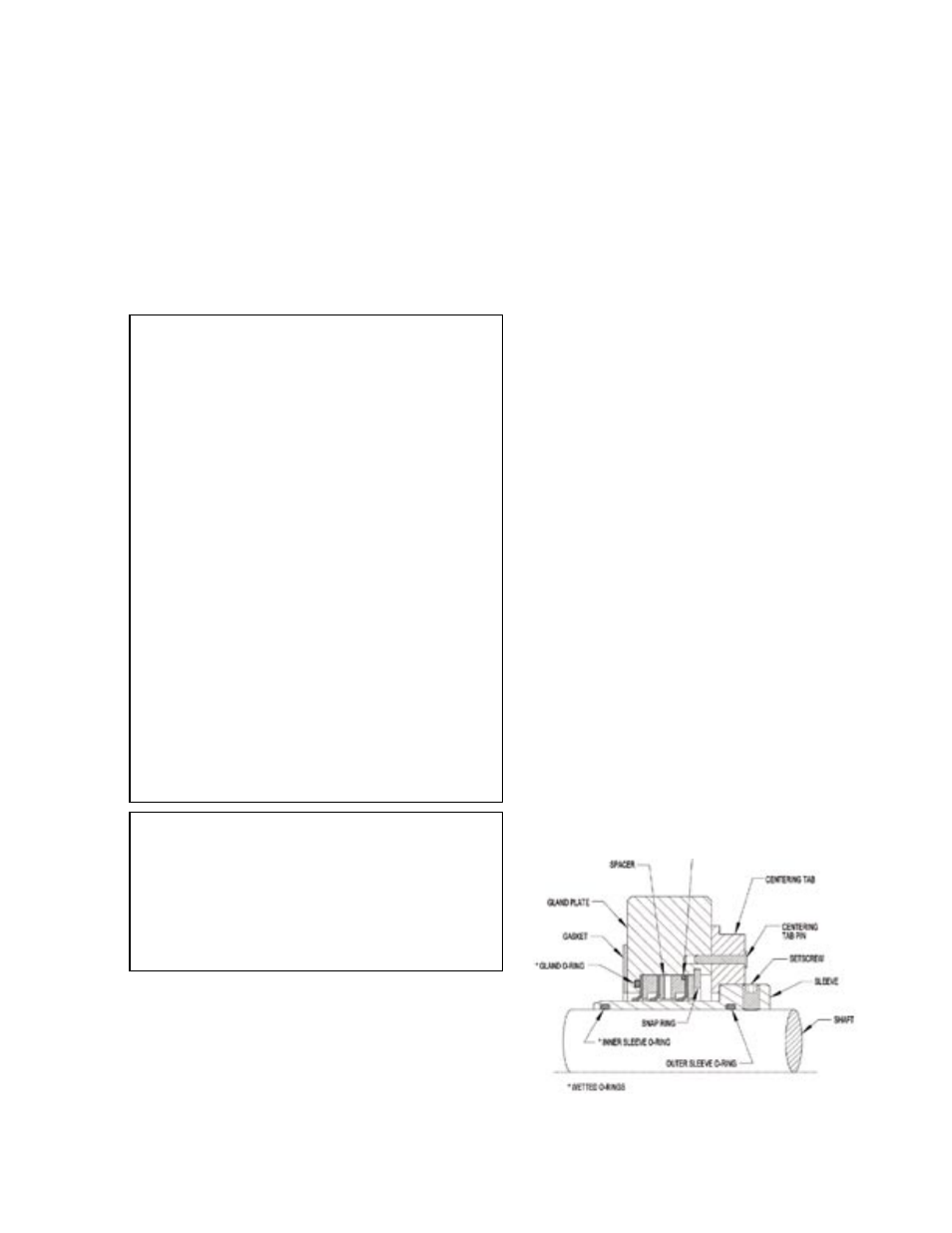

Optional Cartridge Lipseal Seal Replacement

NOTE: Good radial alignment is required for proper

operation of the seals. This is accomplished by the use of

centering tabs provided with each seal. Turn the tabs inward

when installing or removing the seal. Turn them outward for

normal operation of the pump.

MECHANICAL SEAL INFORMATION

DANGER!

Before starting pump, be sure all drive equipment

guards are in place.

Failure to properly mount guards may result in seri-

ous injury or death.

DANGER !

Before opening any Viking pump liquid chamber

(pumping chamber, reservoir, etc.) be sure:

1. That any pressure in the chamber has been

completely vented through the suction or

discharge lines or other appropriate openings or

connections.

2. That the driving means (motor, turbine, engine, etc.)

has been “locked out” or made non-operational so

that it cannot be started while work is being done

on pump.

3. That you know what liquid the pump has been

handling and the precautions necessary to

safely handle the liquid. Obtain a material safety

data sheet (MSDS) for the liquid to be sure these

precautions are understood.

4. That

the timing gearbox to cool before handling

the pump. The oil will become very hot during

normal operation. Allow the timing gearbox oil.

Failure to follow above listed precautionary mea-

sures may result in serious injury or death.

FIGURE 4

TRIPLE LIP CARTRIDGE SEAL

Replacement of the cartridge lipseal seal requires

disassembly of the pump.

REMOVAL

NOTE: The loosening of the seal setscrews and gland

capscrews should always be the first step whenever working

on the pump.

1. Remove the coverplate capscrew and coverplates.

2. Turn the centering tabs inward. Unlock the setscrews

securing the sleeve to the shaft.

3. Follow steps 3 through 10 of PUMP DISASSEMBLY on

page 7.

4. Remove the four capscrews and washers that hold each

seal in place and remove the seals.

INSTALLATION

NOTE: The tightening of the capscrews and seal setscrews

should be the final step in pump assembly.

1. Follow steps 1 through 3 of ASSEMBLY on page 8.

2. Lubricate the ID of the seals.

3. Install the seals on the shafts with the flats toward each

other.

4. Secure the seal gland loosely to the casing with washers

and capscrews.

5.Follow the remaining steps 6 through 13 of ASSEMBLY.

6. Turn the centering tabs outward.

Replacement of the cartridge mechanical seal requires

disassembly of the pump. Follow the pump disassembly and

assembly instructions (See pages 7 through 9) for standard

mechanical seal replacement.

Cartridge Mechanical Seal Replacement