Pump disassembly, Optional packing replacement only, Labyrinth seal – Viking Pump TSM270.2: RL 16 and 25 High Pressure User Manual

Page 6: Warning, Danger

SECTION TSM

270.2

ISSUE

A

PAGE 6 OF 12

SECTION TSM

270.2

ISSUE

A

PAGE 7 OF 12

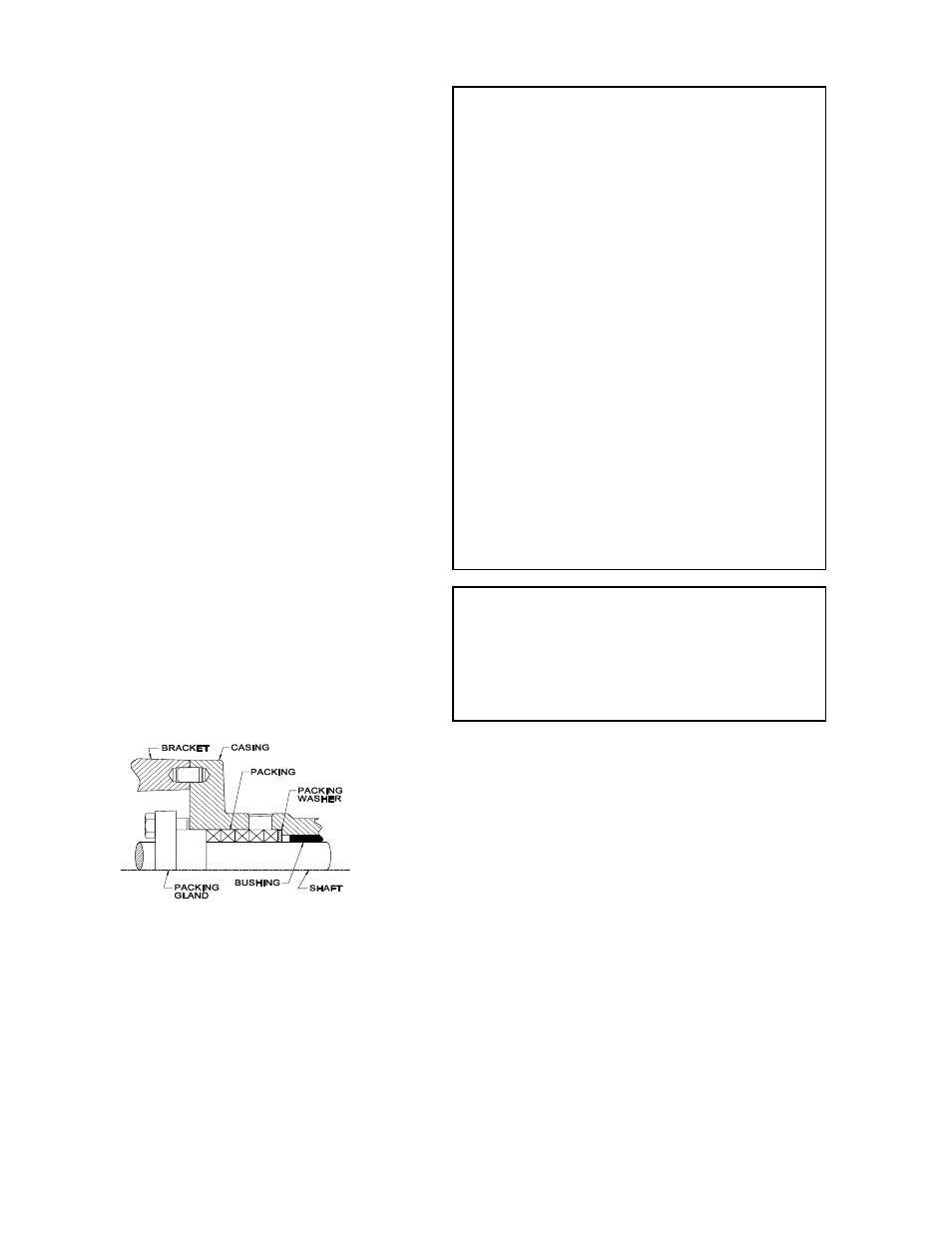

Optional Packing Replacement Only

REMOVAL

1. Remove the packing gland capscrews.

2. If the pump bracket is still assembled, there is enough

room to slide the packing gland back and pull out

the packing with a packing hook, without further

disassembly.

INSTALLATION

1. Follow steps 1 through 4 of ASSEMBLY on page 8.

2. Clean the stuffing box thoroughly and check the shaft for

smoothness. Scored shafts should be replaced.

3. Lubricate the packing rings with an appropriate

lubricant. Install and seat each ring of packing one at

a time, staggering the ring joints 90° apart. Push each

ring in by hand using the packing gland or by tightening

two opposite packing gland capscrews.

4. Install the packing gland washers and capscrews.

Tighten the packing gland until it becomes snug. Do not

over-tighten.

5. On start-up of the pump, carefully tighten the gland

to reduce leakage until a desired leakage rate is

obtained. Excess leakage during the break-in period

is necessary to help lubricate and cool the packing. A

maximum adjustment of approximately 1/8 turn at a time

is recommended. If during this period heating occurs,

back off the gland and allow to run until stuffing box

cools. Then, begin readjustment.

NOTE: Some leakage is required for packing lubrication.

The amount will vary depending on the application. Consult

your authorized Viking representative for more information.

Labyrinth Seal

All labyrinth seals contain 4 common parts:

Stationary Element

Stationary O-ring

Rotating Element

Rotating O-ring

It is recommended to replace any O-rings that are removed

from their initial seat. It is recommended to replace the

entire seal if the stationary and rotating elements become

separated.

FIGURE 5

WARNING:

Do not use the circulation tubing to lift the pump or

casing. Make sure the casing is secured to a work

bench or other stable work surface before working

on the pump.

PUMP DISASSEMBLY

DANGER !

Before opening any Viking pump liquid chamber

(pumping chamber, reservoir, etc.) be sure:

1. That any pressure in the chamber has been

completely vented through the suction or

discharge lines or other appropriate openings or

connections.

2. That the driving means (motor, turbine, engine, etc.)

has been “locked out” or made non-operational so

that it cannot be started while work is being done

on pump.

3. That you know what liquid the pump has been

handling and the precautions necessary to

safely handle the liquid. Obtain a material safety

data sheet (MSDS) for the liquid to be sure these

precautions are understood.

4. That

the timing gearbox to cool before handling

the pump. The oil will become very hot during

normal operation. Allow the timing gearbox oil.

Failure to follow above listed precautionary mea-

sures may result in serious injury or death.

1. Remove the coverplate capscrews and coverplate.

2. Loosen the setscrews and capscrews on the seal

gland. For packing or other seals, refer to the specific

instructions for that option.

NOTE: The loosening of the seal setscrews and gland

capscrew should always be the first step whenever working

on the pump.

3. Drain the oil from the timing gear case by removing the

pipe plug (item 1). Remove the capscrews then carefully

slide the gear case off the driver shaft.

4. Remove the capscrews and shaft guards from the

bracket.

5. Remove the capscrews and head.

6. Straighten out the bearing lockwasher tab on both shafts

(see figure 6). Place a wooden block or brass bar in

between the lobes to block rotation of the shafts. Use

the spanner wrench (Suggested Repair Tools # 5) to

remove the locknut. Remove the wooden block and

insert on the opposite side to restrict movement of the

other shaft. Remove the second locknut. Remove both

of the lockwashers.