Cb a, Danger – Viking Pump TSM163: N-R 337/4337 User Manual

Page 7

SECTION TSM 163

ISSUE

D

PAGE 7 OF 15

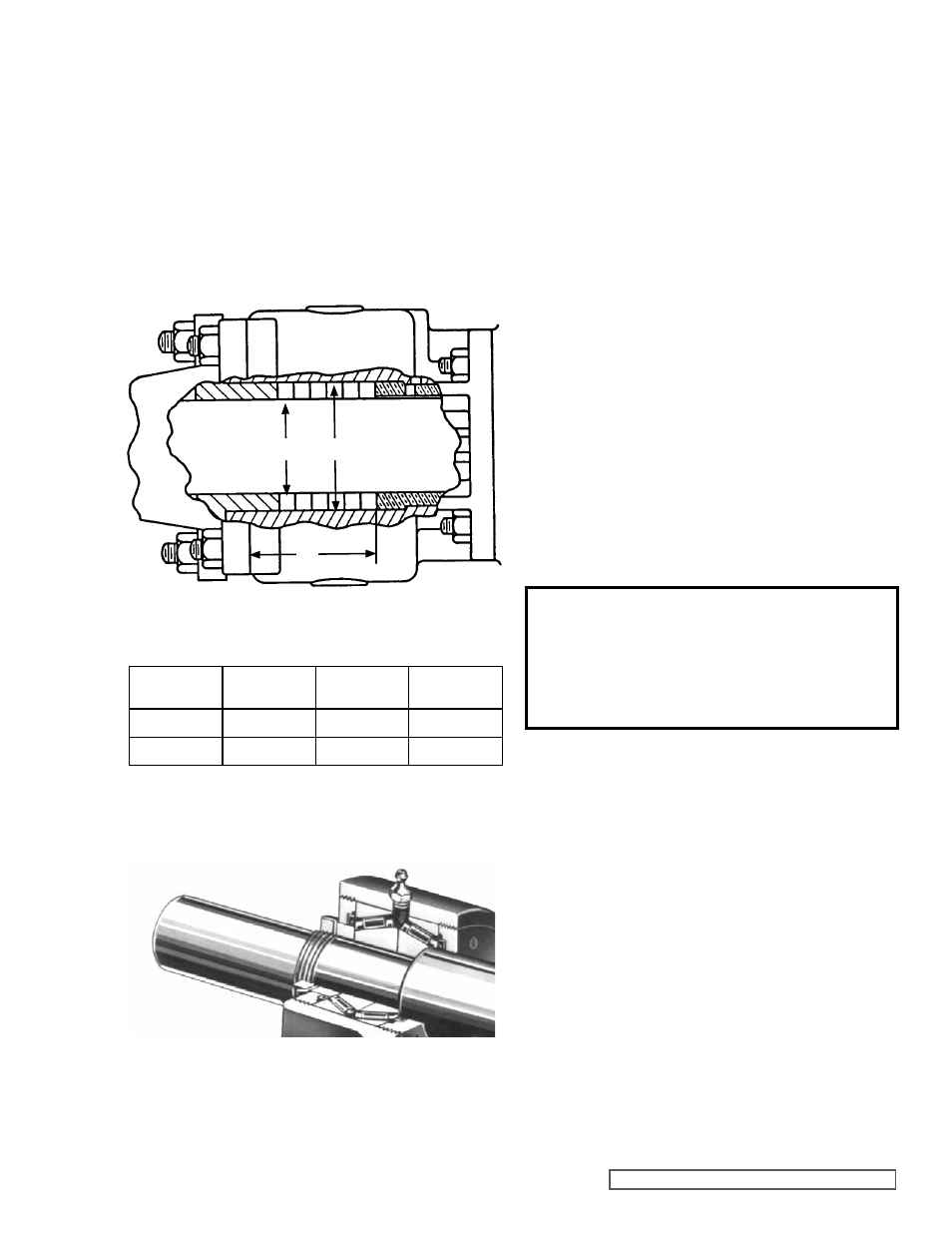

FIgURE 8

STUFFINg BOX DIMENSIONS

7. Push the rotor back against the head.

8. Install the drain plug in the casing.

9. Place packing retainer washer in bottom of packing

chamber and pack pump with new packing. Use packing

suitable for liquid being pumped. Install packing,

staggering the joints from one side of the shaft to the

other. Lubricate packing rings with oil, grease or graphite

to aid assembly. A length of pipe will help to seat each

packing ring.

Refer to Figure 8 below.

10. Install the thrust bearing housing on the end of rotor ring

sleeve and tighten the nuts and capscrews securely. It is

not necessary to use gasket between these parts.

PUMP

MODEL

A

(INCH)

B

(INCH)

C

(INCH)

N337

4.63”

4.69”

3.44”

R337

4.63”

4.69”

3.44”

c

B

a

DANgER !

Before starting pump, be sure all drive

equipment guards are in place.

Failure to properly mount guards may

result in serious injury or death.

FIgURE 9

11. Insert both tapered roller bearings in the thrust bearing

housing, large end of inner races together. It is possible

to install bearings incorrectly, for proper assembly

refer

to Figure 9 below.

12. Install the bearing spacer collar on the shaft next to the

inner race of the roller bearing.

13. Turn the inner end cap into the thrust bearing housing

just far enough to hold in place.

Install the outer end cap and turn in approximately half

way.

14. Insert a length of hardwood or brass bar through the port

opening between the rotor teeth to keep the rotor from

turning.

15. Install the lockwasher placing tang in the keyway on the

shaft. Tighten the locknut to 170-190 ft – lbs. Torque.

Bend one tang of lock washer into slot of locknut. If tang

does not line up with slot tighten lock nut until it does.

Failure to tighten locknut or engage the lock washer tang

could result in early bearing failure and cause damage to

rest of pump.

16. Remove the length of hardwood or brass bar from the

port opening.

17. Install the nuts on the packing gland studs and tighten.

Do not over tighten, as it may cause bind on rotor shaft.

18. Reinstall the suckback tubing to the casing and rotor

bearing sleeve.

19. Lubricate all grease fittings with multi-purpose grease,

NLGI #2.

20. Adjust the pump end clearance. Refer to THRUST

BEARINg AND IDLER END CLEARANCE

ADjUSTMENT, page 12.