Thrust bearing and idler end clearance adjustment, Danger – Viking Pump TSM163: N-R 337/4337 User Manual

Page 12

SECTION TSM 163

ISSUE

D

PAGE 12 OF 15

DANgER !

Before starting pump, be sure all drive

equipment guards are in place.

Failure to properly mount guards may

result in serious injury or death.

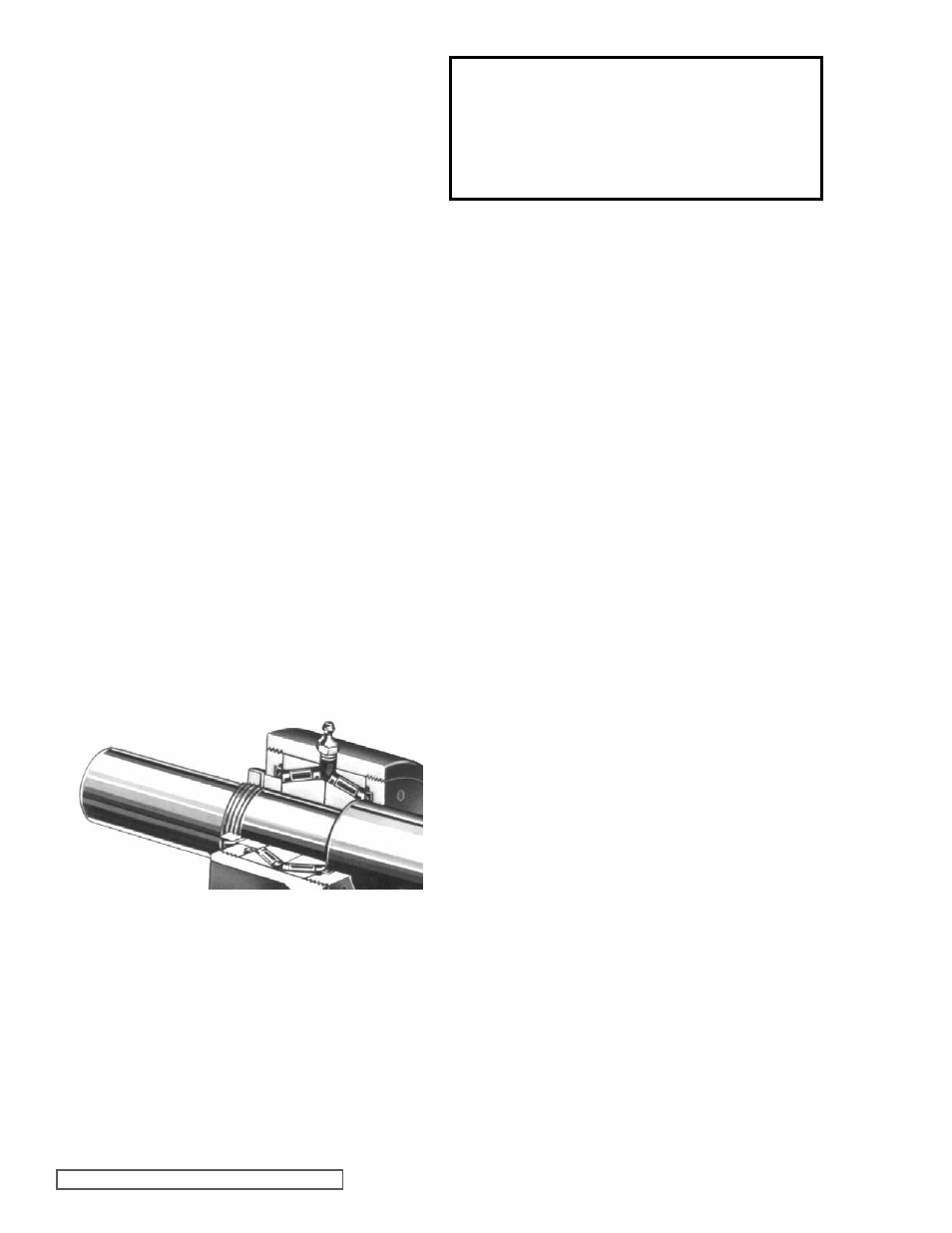

THRUST BEARINg AND IDLER END

CLEARANCE ADjUSTMENT

Use spanner wrench (provided with pump) and turn outer

end cap until rotor is tight against head and rotor shaft cannot

be turned.

With pencil or chalk, make reference mark on bearing housing

and outer end cap. Back off outer end cap approximately

4 holes. One hole is equivalent to .005” of end clearance.

Tighten inner end cap. Check rotor to determine if it turns

freely in the casing. If not, make further adjustment until rotor

does turn in casing.

Standard catalog pumps require the following end clearance

settings; N, .015”, R, .020” minimum. Pumps built for viscous

liquid or high temperature service may require extra end

clearance. Consult factory.

Lock both end caps securely in position with end cap locks

and screws.

NOTE:

The R 4337 pump has a special idler arrangement which

must have its end clearance adjusted prior to setting the rotor

end clearance.

The Carbon Graphite idler bushing extends beyond the idler

face on one side of the idler. This side of the idler is placed

toward the head which allows the Carbon Graphite bushing

to contact the head and provide clearance between the

stainless steel idler face and the head. The Carbon Graphite

bushing extension is 0.008 – 0.012” (

See Figure 1).

The idler bushing has a high interference fit and must be

installed by heat shrinking. The idler must be heated to

600 ºF before installing the idler bushing. The idler bushing is

to extend beyond the idler face 0.008 – 0.012”.

FIgURE 16

19. Place inner end cap with lipseal (lip facing end of shaft)

on shaft.

20. Install thrust bearing housing on end of rotor bearing

sleeve and tighten nuts and capscrews securely.

21. Insert both tapered roller bearings in thrust bearing

housing, large end of inner races together.

CAUTION: It is possible to install bearings incorrectly.

For proper assembly,

refer to figure 16 below.

22. Install bearing spacer collar on shaft next to inner race of

roller bearing.

23. Turn inner end cap into thrust bearing housing just far

enough to hold in place.

Install outer end cap and turn in approximately halfway.

24. Insert length of hardwood or brass bar through port

opening between rotor teeth, to keep rotor from turning.

25. Install lockwasher with tang in keyway on shaft. Tighten

locknut to 170-190 ft – lbs. Torque. Bend one tang of

lock washer into slot of locknut. If tang does not line up

with slot, tighten locknut until it does. Failure to tighten

locknut or engage lockwasher tang could result in early

bearing failure and cause damage to rest of pump. Bend

one tang of lockwasher into slot of locknut.

26. Remove the length of hardwood or brass bar from port

opening.

27. Lubricate all grease fittings with multi-purpose grease,

NLGI # 2.

28. Adjust pump end clearance. Refer to THRUST BEARINg

AND IDLER END CLEARANCE ADjUSTMENT.