Pressure relief valve instructions, Assembly disassembly, Danger – Viking Pump TSM164: GG-AL 4197 User Manual

Page 9

SECTION TSM 164

ISSUE

F

PAGE 9 OF 10

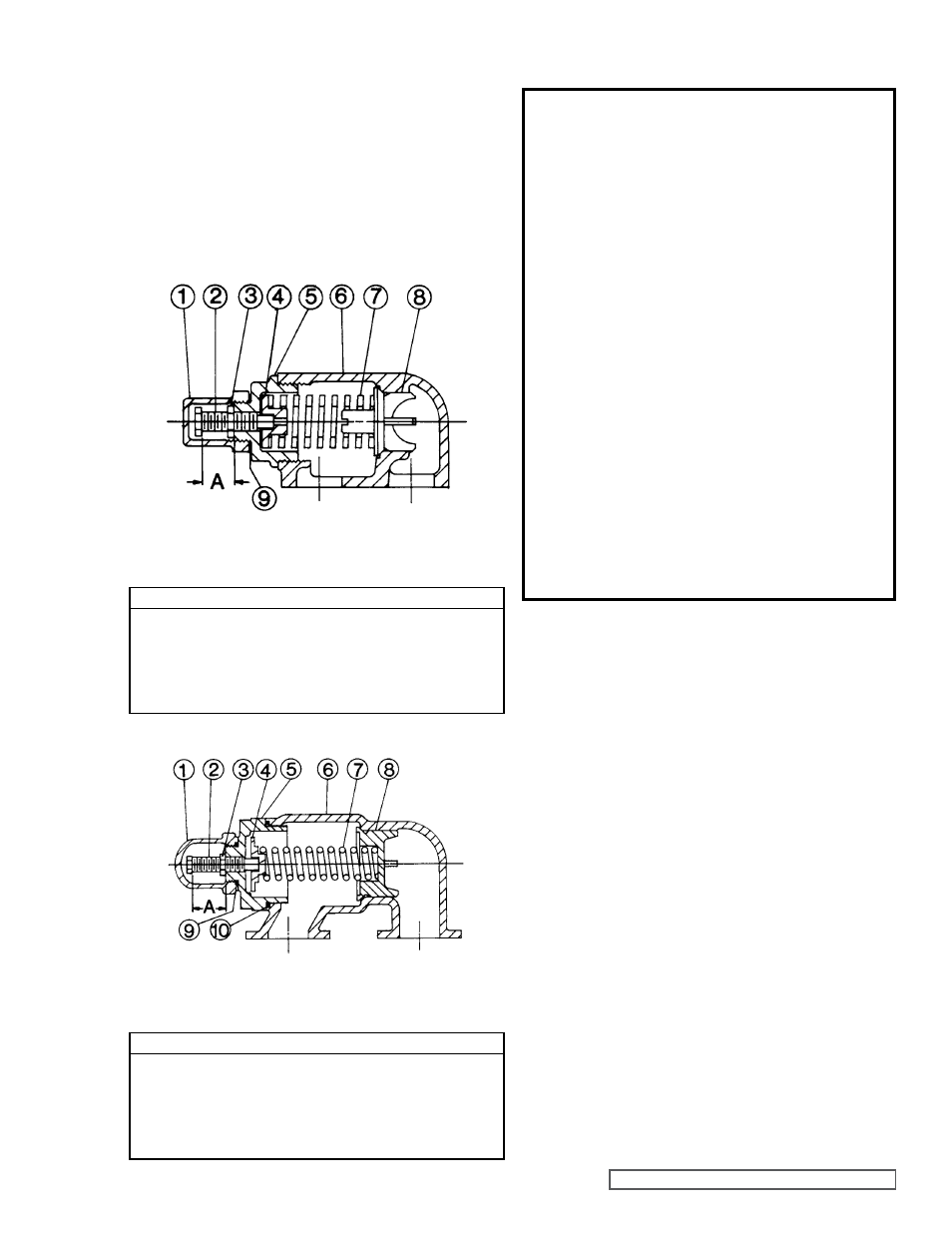

Mark the valve and head before disassembly to ensure

proper reassembly.

1. Remove the valve cap.

2. Measure and record the length of extension of the

adjusting screw. Refer to

“A” on figures 14 and 15.

3. Loosen the locknut and back out the adjusting screw

until spring pressure is released.

4. Remove the bonnet, spring guide, spring and poppet

from the valve body. Clean and inspect all parts for wear

or damage and replace as necessary.

Reverse the procedures outlined under

“Disassembly”

above. If the valve is removed for repair, be sure to replace in

the same position. The relief valve adjusting screw cap must

always point towards suction side of the pump. If the pump

rotation is reversed, remove the relief valve and turn end for

end. Refer to

figure 3, page 3.

PRESSURE RELIEf VALVE

INSTRUCTIONS

fIgURE 14

VALVE - gg, HJ and HL SIZES

fIgURE 15

VALVE - AS, AK and AL SIZES

VALVE - LIST Of PARTS

1.

Valve Cap

6.

Valve Body

2.

Adjusting Screw

7.

Spring

3.

Lock Nut

8.

Poppet

4.

Spring Guide

9.

Cap Gasket

5.

Bonnet

VALVE - LIST Of PARTS

1.

Valve Cap

6.

Valve Body

2.

Adjusting Screw

7.

Spring

3.

Lock Nut

8.

Poppet

4.

Spring Guide

9.

Cap Gasket

5.

Bonnet

10.

Bonnet Gasket

ASSEMBLY

DISASSEMBLY

1. A press must be used for installation.

2. Be certain the bushing is started straight.

3. Do not stop pressing the operation until the bushing is in

the proper position, as starting and stopping may result

in a cracked bushing.

4. Check the bushing for cracks after installation.

DANgER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor, turbine,

engine, etc.) has been “locked out”

or made non-operational so that it

cannot be started while work is being

done on pump.

3. That you know what liquid the pump

has been handling and the precautions

necessary to safely handle the liquid.

Obtain a material safety data sheet

(MSDS) for the liquid to be sure these

precautions are understood.

failure to follow above listed

precautionary measures may result in

serious injury or death.