Assembly, Caution – Viking Pump TSM164: GG-AL 4197 User Manual

Page 6

SECTION TSM 164

ISSUE

F

PAGE 6 OF 10

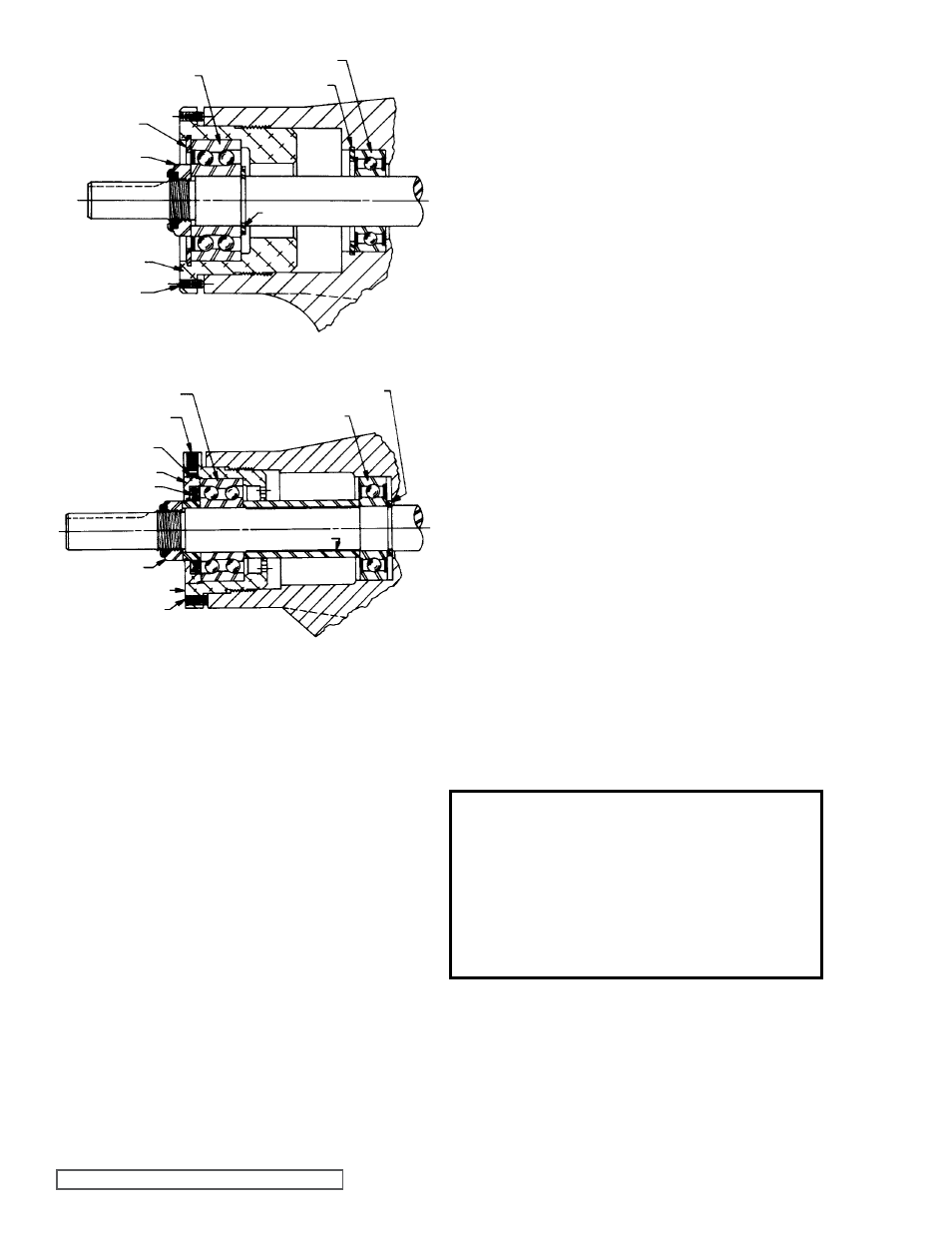

SHAfT SNAP RINg

OUTER

BALL BEARINg

BEARINg

HOUSINg

INNER SNAP RINg

INNER BALL BEARINg

SETSCREW

SHAfT

OUTER

SNAP RINg

LOCKNUT

fIgURE 7

THRUST BEARINg ASSEMBLY gg, HJ AND HL SIZES

fIgURE 8

THRUST BEARINg ASSEMBLY AS, AK AND AL SIZES

BEARINg RETAINER WASHER

BEARINg SPACER

SETSCREW

LOCKNUT

LIP SEAL

END CAP

NYLON INSERT

SHAfT

INNER BALL BEARINg

BEARINg HOUSINg

SETSCREWS

BALL BEARINg

ASSEMBLY

PTfE fitted Mechanical Seal

1. Installing New Seal: See figures 9 thru 13.

GENERAL INFORMATION:

Mechanical seals for HJ, HL, AS, AK and AL4197 size

pumps are of the drive set screw type. Mechanical seals for

GG4197 size pump are friction driven and are pressed onto

the rotor hub.

Installation sleeves are furnished with replacement seals

for GG, AS, AK, size pumps. (this is not necessary with HJ

and HL pumps).

NOTE: Cleanliness during installation is

essential to seal performance. Never allow the seal faces to

contact a dirty surface.

ORDER OF ASSEMBLY:

1. Stationary seat and seat ring in casing

2. Installation sleeve on the shaft (where appropriate)

3. Seal rotating portion on the shaft

4. Rotor and shaft into casing

5. Head with gasket and idler onto the casing

PREPARATION:

Remove burrs from threads and gently radius leading edges

on rotor shaft. Use 300 grit paper to radius the edges and to

polish the shaft at the seal area. Clean the rotor hub, shaft

and seal seat bore in casing, making sure they are free from

dirt and grit.

Place installation sleeve on shaft, wide end against shaft

shoulder. See

figure 10, page 7.

STATIONARY SEAT ASSEMBLY:

Refer to

figures 9 and 11, page 7.

All models-Coat the outside diameter of the seat ring

assembly and the inside diameter of the seal housing bore

with SAE 30 oil. Align the slot in the back of the seal seat with

anti-rotation pin in the bottom of the casing seat bore and

start the seal seat into this bore. Protect the lapped surface

of the seal seat with a disc of clean cardboard and press the

seal seat into this bore until it is firmly at the bottom of the

bore. A hammer handle or wood dowel will serve to press

against the cardboard disc and seat.

ASSEMBLY OF SEAL ROTATING PORTION:

Models HJ, HL, AS, AK and AL4197 (refer to figure 12,

page 7) - Coat the inside diameter of the rotating portion

assembly, shaft and tapered sleeve with SAE 30 weight oil.

Be sure the shaft is free of any scratches, nicks and burrs.

Check the internal parts (PTFE rings and carbon washer) of

the rotating portion so that the parts concentrically align so

they will not be pinched and twisted at installation. With the

shaft pointed upward, push the rotating portion down along

the large shaft onto the large diameter. Remove the holding

clips, which hold the spring-loaded disc away from PTFE and

carbon parts. See

figure 10, page 7. Push the seal against

the rotor hub and tighten the set screws to lock the seal to

the shaft. Remove the tapered sleeve.

MODEL gg4197 - rotating portion of the mechanical seal

for GG4197 size pump does not have set screws to drive

it and must depend upon interference fit with the rotor hub. See

figure 12, page 7. The rotating portion must be disassembled

before the retainer (cartridge containing spring, disc, PTFE

wedges and carbon face) can be pressed upon rotor hub.

See

figure 11, page 7.

To disassemble the rotating portion of the seal, compress the

carbon face and rapidly depress the retaining ring through

the notch at the end of the retainer cartridge, as shown in

figure 15, page 9.

Press the retainer cartridge onto the rotor hub. See

figure 12,

page 7.

At the factory, an installation tube is used to press the

retainer cartridge onto the rotor hub. In lieu of a special tool,

a 6 1/2” length of one-inch schedule 40 pipe or some blocks

of wood and a light hammer can be used.

Lubricate the rotor hub with PTFE paste, grease or SAE 30

oil and start retainer onto the leading edge of the rotor hub as

evenly as possible.

CAUTION !

Do not allow the compressed spring to be

released suddenly, which might send met-

al parts flying. Protect your eyes! Protect

the carbon face and the PTfE parts from

damage or contamination. Disassemble

the spring and disc by removing the hold-

ing clips around the outside.