Viking Pump TSM164: GG-AL 4197 User Manual

Page 7

SECTION TSM 164

ISSUE

F

PAGE 7 OF 10

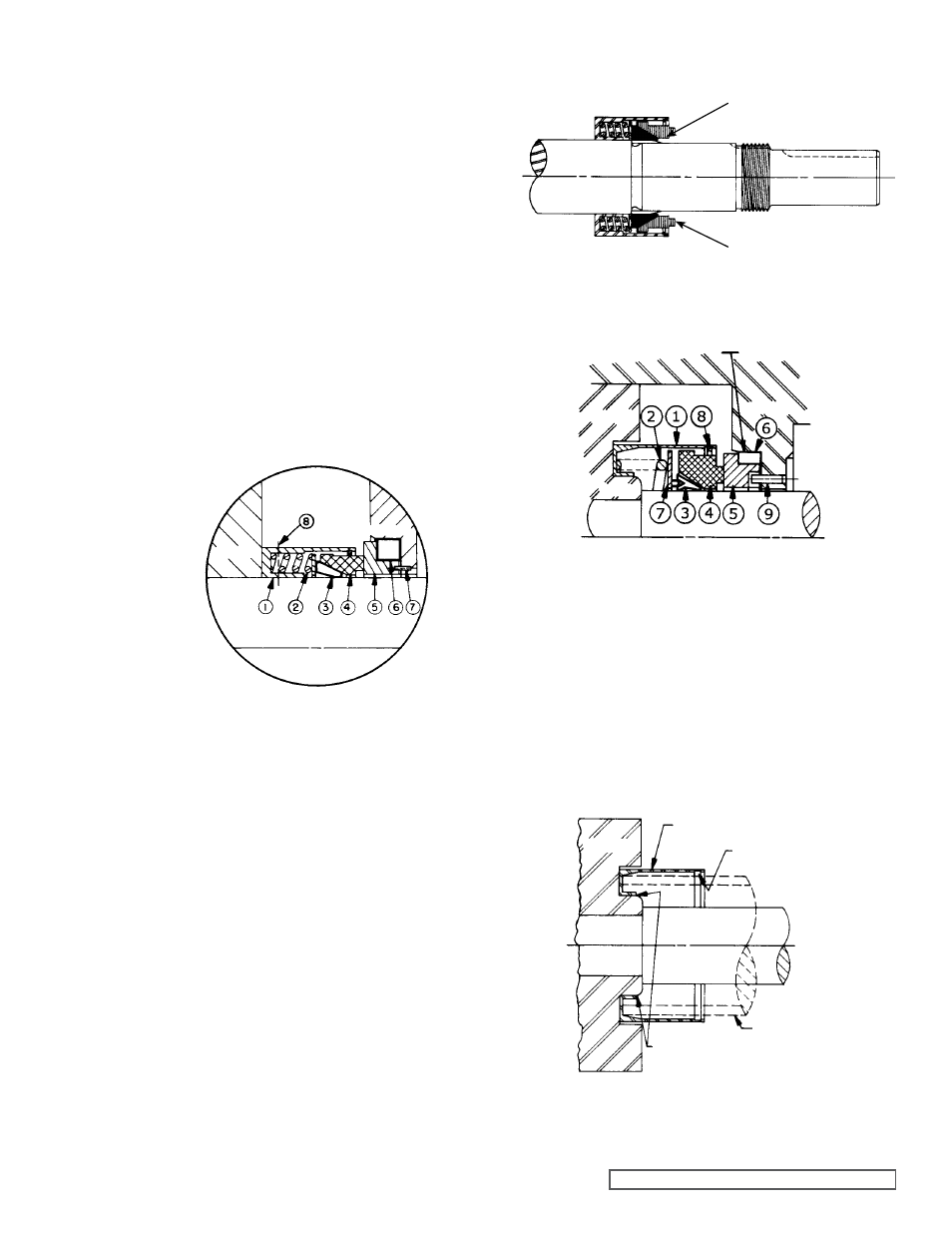

fIgURE 9

fIgURE 11

gg4197 SEAL RETAINER CARTRIDgE ON ROTOR HUB

fIgURE 12

Insert one inch pipe onto the retainer cartridge and press it

against the rotor hub, or, with a block of wood in each hand

push on the outside edge on the side to force the retainer

down the hub. It may be necessary to use a length of hard

wood and a light hammer to completely set the retainer

cartridge against the back of the rotor.

Check dimensionally from the end of the retainer to a

machined portion on the back of the rotor at least two places

180º apart. Runout should not exceed 0.003” (the plane

formed by the end of the retainer should be perpendicular to

the shaft as closely as possible).

Clean off the assembly just installed. Insert the spring and

disc. Lubricate the two piece PTFE wedge inside and outside

with SAE 30 oil. Place the tapered sleeve furnished with

the replacement seals on the shaft against the largest shaft

diameter and coat it with SAE 30 oil. Push the PTFE wedge

assembly over the tapered sleeve and using the carbon

washer, push the wedge onto the retainer against the disc.

Align the retainer with carbon washer indents, compress

and secure with retainer ring. When the carbon face is

compressed against spring, some “drag” should be felt, but

the spring must be able to push the wedge and carbon face

out against the retainer ring.

2. Remove the installation sleeve.

3. All models - Flush sealing faces of both the rotary

member and the seal seat with light oil and install the

rotor and shaft. Push the rotor and shaft into the casing

slowly until the ends of the rotor teeth are just below the

face of the casing.

Place the gasket on the head and install the head and

idler assembly on the pump. The pump head and casing

were marked before disassembly to ensure proper

reassembly. If not, be sure the idler pin, which is offset in

the pump head, is positioned toward and equal distance

between the port connections to allow for proper flow of

liquid through the pump.

COAT SHAfT AND TAPERED SLEEVE

WITH LIgHT OIL BEfORE ASSEMBLY

TAPERED SLEEVE

MECHANICAL SEAL

(ROTARY MEMBER)

fIgURE 10

MECHANICAL SEAL fOR

MODELS HJ, HL, AS, AK, AL4197

1. Retainer Cartridge

2. Springs

3. Wedge

4. Rotating Face (Washer)

5. Stationary Seat

6. Seat Ring (Gasket)

7. Anti-Rotation Pin

8. Drive Set Screws

SEAL SEAT BORE

ROTOR

CASINg

HUB

MECHANICAL SEAL fOR gg4197

1. Retainer Cartridge

2. Springs

3. Wedge

4. Rotating Face (Washer)

5. Stationary Seat

6. Seat Ring (Gasket)

7. Disc

8. Retaining Ring

9. Anti-Rotation Pin

ROTOR

SHAfT

INTERfERENCE

fIT

RETAINER CARTRIDgE

gROOVE fOR

RETAININg RINg

TUBULAR

INSTALLATION

TOOL

CASINg

SHAfT

ROTOR