Special information, Maintenance – Viking Pump TSM143: N-P 335/4335 User Manual

Page 2

SECTION TSM

143

ISSUE

E

PAGE 2 OF 15

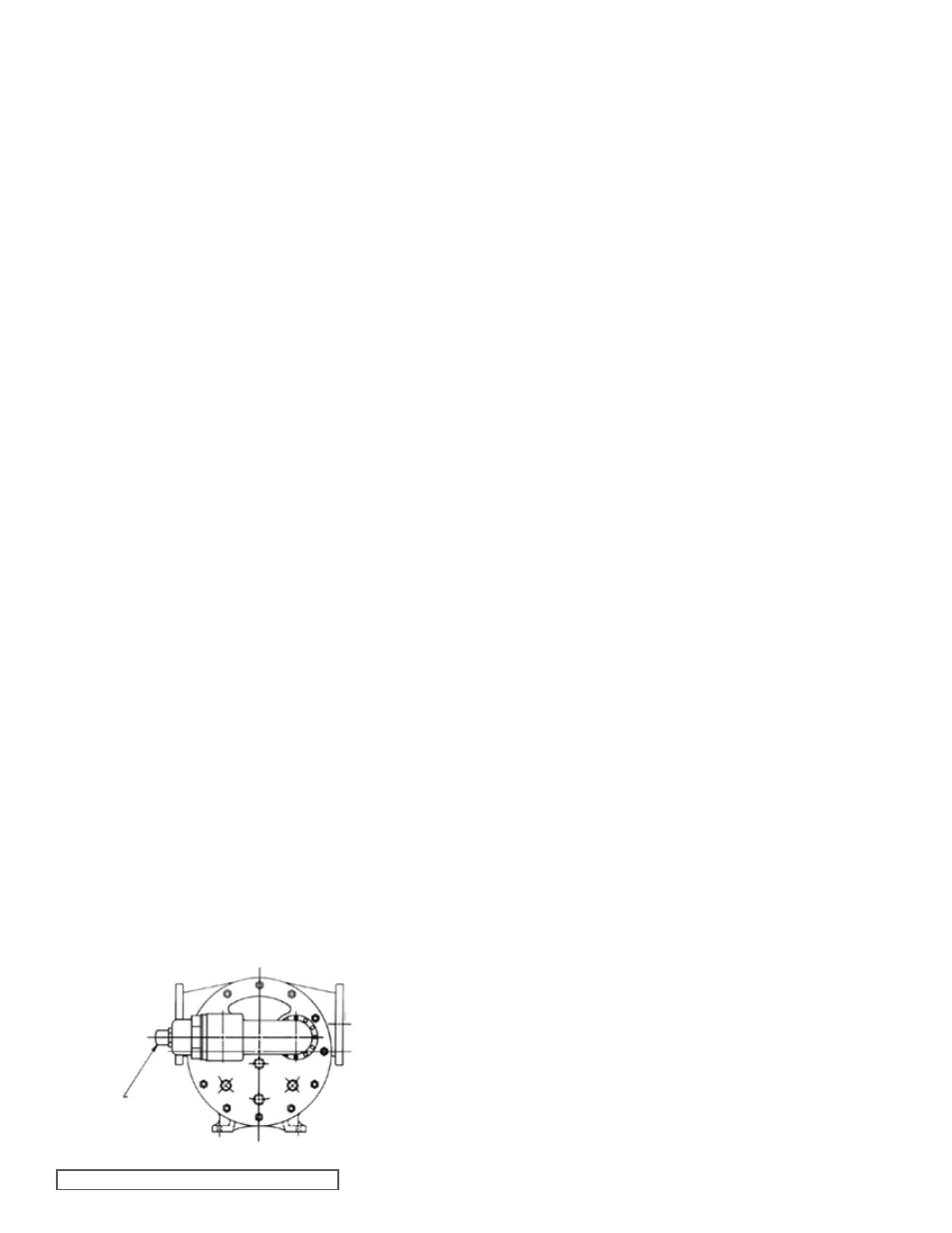

fIGURE 2

ROTATION: Viking pumps operate equally well in a clockwise

or counterclockwise rotation. Shaft rotation determines which

port is suction and which is discharge. The suction port

location is where pumping elements (gear teeth) come out

of mesh.

CIRCULATION LINES: are standard equipment (N & R size

only) and must be properly connected. Packed pumps have

a line connected from the packing chamber to the discharge

port. Mechanical seal pumps have a line connected from

the seal chamber to the suction port. If the pump rotation is

reversed be sure the circulation lines are connected to the

suction or discharge port as noted above to avoid excessive

leakage or damage to pump. If the pump is handling heated

product be sure the circulation line is insulated to assure

continued flow.

The jacketed head (R & P only, optional on N size) and

rotor bearing sleeve provide large chambers at both ends

of the pumping chamber for temperature control of product

in the pump. These features do not alter basic steps in the

disassembly and assembly of your pump.

PRESSURE RELIEF VALVES:

1. Viking pumps are positive placement pumps and must

be provided with some sort of pressure protection. This

may be a relief valve mounted directly on the pump, an

inline pressure relief valve, a torque limiting device or a

rupture disk.

2. A non-jacketed relief valve is standard on these pumps.

Options include plain and jacketed relief valves. N size

pumps with a jacketed head with a relief valve is not

available . R size pumps are standard with a jacketed

head but also have both plain and jacketed relief valve

available as options. P size pumps are standard with a

jacketed head and non-jacketed relief valve.

3. If the pump rotation is to be reversed during operation,

pressure protection must be provided on both sides of

pump.

4. The relief valve adjusting screw cap must always point

towards suction side of pump. If pump rotation is

reversed, remove the pressure relief valve and turn end

for end. Refer to Figure 2.

5. Pressure relief valves cannot be used to control the pump

flow or regulate the discharge pressure.

For additional information on pressure relief valves, refer to

Technical Service Manual TSM000 and Engineering Service

Bulletin ESB-31.

SPECIAl INfORMATION

LUBRICATION: External lubrication must be applied slowly

with a handgun to all lubrication fittings every 500 hours of

operation with multi-purpose grease, NLGI # 2. Do not over-

grease. Applications involving very high or low temperatures

will require other types of lubrication.

Refer to Engineering

Service bulleting ESb-515. Consult factory with specific

lubrication questions.

PACKING ADJUSTMENT: New packed pumps require an

initial packing adjustment to control leakage as the packing

“runs in”. Make initial adjustments carefully and do not

over-tighten the packing gland. After the initial adjustment,

inspection will reveal the need for packing gland adjustment

or packing replacement.

Refer to instructions under

DISASSEMbly, page 4, and ASSEMbly, page 6, regarding

repacking the pump.

CLEANING PUMP: Keep the pump as clean as possible.

This will facilitate inspection; adjustment and repair work and

help prevent overlooking a dirt covered grease fitting.

STORAGE: If the pump is to be stored, or not used for six

months or more, the pump must be drained and a light coat

of non-detergent SAE 30 weight oil must be applied to all

internal pump parts. Lubricate fittings and apply grease to

the pump shaft extension. Viking suggests rotating the pump

shaft by hand one complete revolution every 30 days to

circulate the oil.

SUGGESTED REPAIR TOOLS: The following tools must

be available to properly repair Series 335 and 4335 pumps.

These tools are in addition to standard mechanics’ tools such

as open end wrenches, pliers, screwdrivers etc. Most of the

listed items can be obtained from an industrial supply house.

1. Soft Headed Hammer

2. Allen Wrenches (for some mechanical seals and set

collars)

3. Packing hooks, flexible (packed pumps)

Large for 0.375 inch and up cross section packing

4. Bearing locknut spanner wrench

(Source: #471 J.H. Williams & Co. or equal)

5. Spanner wrench (Supplied with pump)

Viking Part Number 3-810-009-631

6. Brass Bar

7. Arbor Press

SPECIAL MECHANICAL SEALS: can be installed in a

modified stuffing box.

Extra care must be taken in the repair of pumps with

mechanical seals. Read and follow all special information

supplied with the pump.

MAINTENANCE

The Series 335 and 4335 pumps are designed for long

trouble free life under a wide variety of application conditions

with a minimum of maintenance. The points listed below will

help provide long service life.

INLET

OR

SUCTION

OUTLET

OR

DISCHARGE

RELIEF VALVE

ADJUSTING

SCREW CAP