Assembly – Viking Pump TSM143: N-P 335/4335 User Manual

Page 10

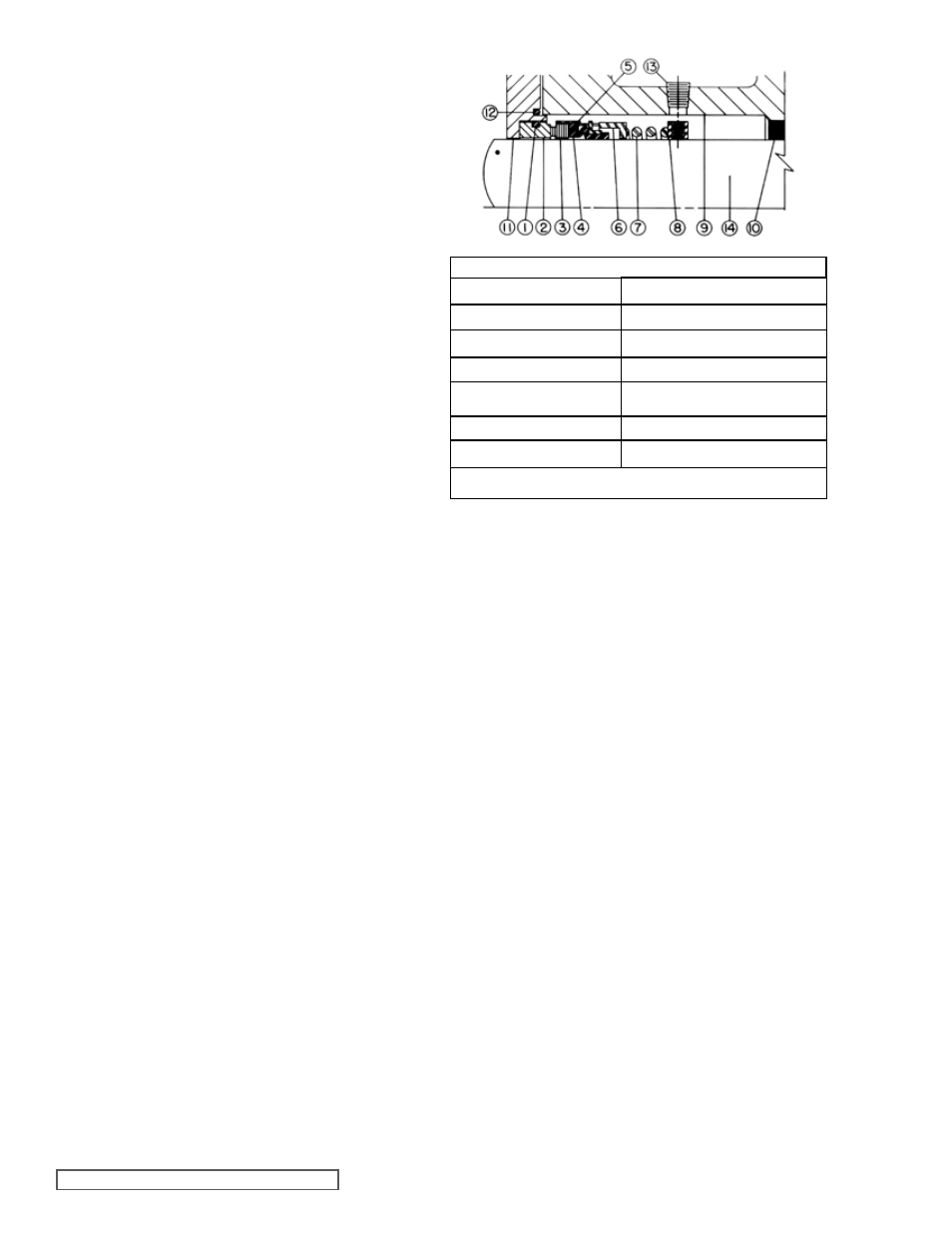

lIST Of PARTS

1. O-Ring Seat Gasket

8. Set Collar with set screws

2. Stationary Seat

9. Rotor Bearing Sleeve

3. Rotating Face (Washer) 10. Rotor Bearing Sleeve Bushing

4. Bellows

11. Seal Holder Plate

5. Metal Parts

(retainer, drive band)

12. O-Ring Gasket for seal holder

plate

6. Spring Adapter

13. Pipe Plug

7. Spring

14. Shaft

NOTE: Items one through seven comprise the complete mechanical seal

SECTION TSM

143

ISSUE

E

PAGE 10 OF 15

ASSEMbly

Standard Mechanical Seal (Synthetic Rubber Bellows Type)

Prepare all parts for reassembly ahead of time. Pack roller

bearings with multi-purpose grease, NLGI # 2 and have all

new gaskets on hand.

Be especially careful to keep mechanical seal parts clean.

Minute dirt particles especially on the seal faces, will cause

leakage. Never touch the seal faces with anything except

clean hands or a clean cloth.

Once the rotating portion of mechanical seal is installed on

rotor shaft, it is necessary to assemble parts as quickly as

possible to ensure the seal does not stick to the shaft in the

wrong axial position. The seal should be expected to stick to

the shaft after several minutes setting time.

1. Deburr the threads on the rotor shaft with a fine file and

place a layer of tape over the threads to protect the rotor

bearing sleeve bushing during assembly. Gently radius

leading edge of the largest diameter on the shaft (.03

inch is sufficient to aid in seal installation). Smooth the

radius with a very fine grit emery cloth. Polish the rotor

shaft from leading edge through mechanical seal area

with the emery cloth. Any scratches left on shaft in seal

area will provide leakage paths under mechanical seal.

2. Install the rotor bearing sleeve and gasket on the casing.

Coat both sides of the gasket with thread sealant (pipe

locks and with a spanner wrench, remove the end caps.

Examine the lipseal and replace if worn.

Remove the roller bearings.

10. Remove the nuts and capscrews and take off the thrust

bearing housing.

11. Remove the nuts holding the seal plate and remove seal

plate. The stationary seal seat can be removed from the

seal plate and the rotating portion of the seal from the

rotor bearing sleeve, remove the spring and set collar

from the bottom of the seal chamber.

12. Check rotor the bearing sleeve bushing while the rotor

bearing sleeve is mounted on the casing. If worn, the

bushing must be replaced.

Disconnect the flush line and remove the rotor bearing

sleeve from the casing.

A press must be used to remove the old bushing. If

the bushing has a shoulder on the stuffing box end,

it must be pressed out from the mechanical seal end

of the rotor bearing sleeve. Carbon graphite bushings

are standard for Model 4335 pumps. To replace carbon

graphite bushings, refer to

INSTAllATION CARbON

GRAPhITE bUShINGS, page 12.

13. Clean all parts thoroughly and examine for wear and

damage. If lipseal replacement is needed, press in the

end cap with the lip facing the end of the shaft. Check

the idler bushing and idler pin, replace if necessary.

If the idler pin is to be replaced, the oil groove on the

pin must be installed facing the center of the crescent

on the head.

If the idler bushing is to be replaced, a press must

be used to remove the old bushing and install new.

The bushing position after being pressed in should

be flush with teh face of the idler. For carbon graphite

idler bushing, refer to

INSTAllATION Of CARbON

GRAPhITE bUShINGS, page 12.

14. Wash the bearing in clean solvent. Blow out bearings

with compressed air. Do not allow the bearings to spin;

turn the bearing slowly by hand. Spinning the bearings

will damage the race and rollers. Make sure the

bearings are clean, then lubricate with non-detergent

SAE 30 weight oil and check for roughness. Roughness

can be determined by turning the outer race by hand.

CAUTION: do not intermix the inner and outer races for

the roller bearings.

15. Examine the casing for wear. Check the condition of

the casing at the seal area (surface between suction

and discharge ports). If the surface is in good condition,

the casing need not be replaced. When making major

repairs, such as replacement of a rotor, it is usually

considered advisable to install a new head and idler.

When making minor repairs, when only an idler bushing

and idler pin are required, other new parts are usually

not necessary.

16. Inspect the mechanical seal for wear or damage.

Refer to Figure 14 for mechanical seal list of parts. In

general, if the pump has been operated long enough

to exhibit other worn parts, it is likely the seal will have

fIGURE 14 MEChANICAl SEAl

to be replaced. Replacing individual seal parts is not

recommended, i.e., a used seal washer will not perform

satisfactorily when run against a new stationary seat.