Danger, Optional mechanical seal (ptfe fitted type), Disassembly – Viking Pump TSM143: N-P 335/4335 User Manual

Page 12: Assembly

SECTION TSM

143

ISSUE

E

PAGE 12 OF 15

DANGER !

before starting the pump, be sure all drive

equipment guards are in place.

failure to properly mount guards may result in

serious injury or death

OPTIONAl MEChANICAl SEAl

(PTfE fitted Type)

Three components are furnished in the mechanical seal

assembly:

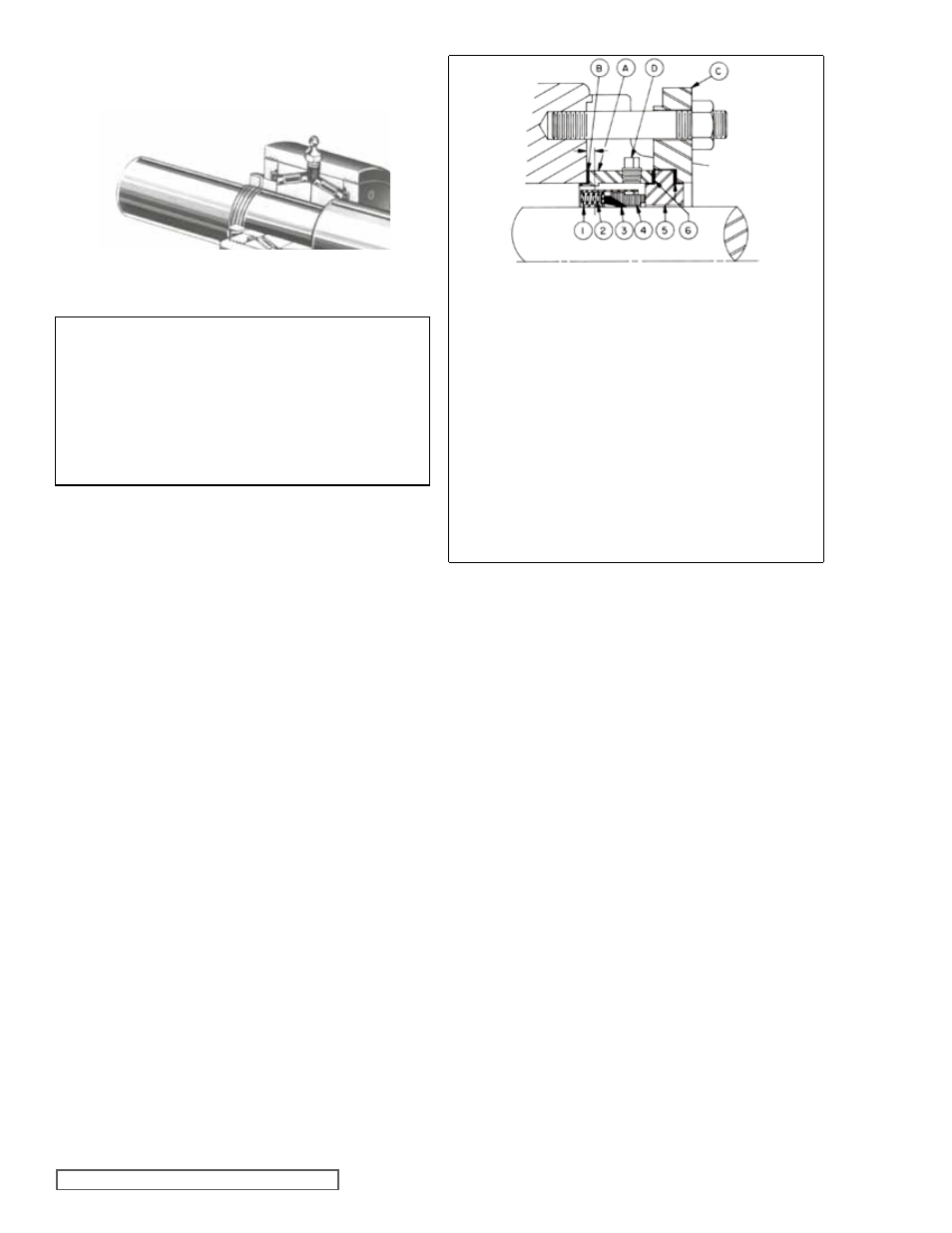

Refer to Fgure 18, item numbers 1 thru 6.

1. The rotating assembly in which a retainer cartridge

encloses a spring loaded PTFE shaft ring and polished

rotating face. Set screws located around the outside of

the retainer cartridge are provided for securing rotating

assembly to pump shaft.

2. The stationary seal seat.

3. Two seal seat gaskets.

Three pump parts necessary for mounting PTFE mechanical

seal are illustrated in Figure 18, item letters A, B, C and D.

1. The packing box extension, has a machine pilot on the

end for installation in the rotor bearing sleeve and two

tapped holes for the seal flush.

2. The packing box extension gasket.

3. The seal plate is mthe achined to accept seal seat and

gasket.

fIGURE 18

PTFE Fitted Mechanical Seal Assembly

For Models N-R4333, 4335 & 4337

1.

Retainer Cartridge

2. Springs

3.

PTFE Shaft Ring (wedge)

4.

Rotating Face (washer)

5.

Stationary Seal Seat

6.

Seat Gaskets

Seal Mounting Parts

A.

Packing box extension

B.

Packing box extension gasket

C.

Seal plate

D.

Flush openings

DISASSEMbly

1. Disassemble the pump per steps 1 thru 10 on page 8

under

MEChANICAl SEAl DISASSEMbly.

2. Remove the seal plate nuts from the studs and remove

the seal plate, gaskets and stationary seat.

3. If the pump is equipped with a flush line, disconnect

from the packing box extension.

4. Remove the packing box extension and gasket.

5. Loosen the set screws in the mechanical seal retainer

cartridge and remove from the rotor shaft. Refer to

Figure 18.

ASSEMbly

1. Reassemble the pump per steps 1 thru 9 on pages 10

& 11,

under

ASSEMbly, STANDARD MEChANICAl

SEAl. Step 1 (deburring shaft) is very critical prior to

the seal assembly.

NOTE: The tapered installation sleeve is available from

factory, at additional cost, for the N & R size pumps.from

Viking Pump Division.

2. Coat the large diameter of shaft, tapered sleeve, and

inside diameter of seal with non-detergent SAE 30

weight oil.

fIGURE 17