Thrust bearing adjustment, Installation of carbon graphite bushings – Viking Pump TSM143: N-P 335/4335 User Manual

Page 13

SECTION TSM

143

ISSUE

E

PAGE 13 OF 15

3. Place the tapered installation sleeve (if on hand) and

install the seal on the shaft over tthe apered sleeve.

Position the seal on the shaft inside the rotor bearing

sleeve bore with end of seal located .19 inch inside

the machined face of the rotor bearing sleeve. Refer to

Figure 18

.

4. Tighten all the seal drive set screws securely to the

shaft.

5. Remove the tapered installation sleeve.

6. Place the gasket on the packing box extension and

install the extension with the machined pilot inside the

rotor bearing sleeve bore.

7. Place the seat gasket over the shoulder of the stationary

seal seat and insert seat into the seal plate. Place the

remaining seat gasket over shoulder of polished surface

of stationary seat. Refer to Figure 18.

8. Place the seal plate with the stationary seat over the

mounting the studs and push the shoulder of stationary

seat into the packing box extension, the polished face

against the carbon rotating face.

9. Install the nuts on mounting studs and against seal

holder. Tighten the nuts evenly so the seal plate

and stationary seat will not be distorted when seal is

compressed.

10. Reassemble flush line to packing box extension.

AT ThIS POINT, fINISh ASSEMbly PROCEDURES

STARTING AT STEP 18, page 10.

ThRUST bEARING ADJUSTMENT

Loosen the capscrews retaining the end cap locks on both

the inner and outer end caps. Slide the end cap locks out

far enough so the pins are no longer in the end cap retaining

holes. Using the spanner wrench provided with the pump,

turn the inner end cap towards the pump. Turn the outer

end cap in until the rotor shaft cannot be turned. With grease

pencil or chalk, make a reference mark on the bearing

housing OD and outer end cap. Back off the outer end cap

approximately 4 holes. One hole is equivalent to .005 inch

end clearance. Align the nearest end cap hole with the outer

end cap lock. Tighten the setscrew holding this lock. Tighten

the inner end cap until it is snug. Do not over tighten. Back

off slightly to align the nearest end cap hole with the end cap

lock. Tighten this setscrew. It is important not to tighten the

inner end cap to make the end cap lock align. This will cause

the tapered roller bearings to run too tightly and heat up.

Turn the rotor shaft to make sure it turns freely. If not, repeat

the above procedure.

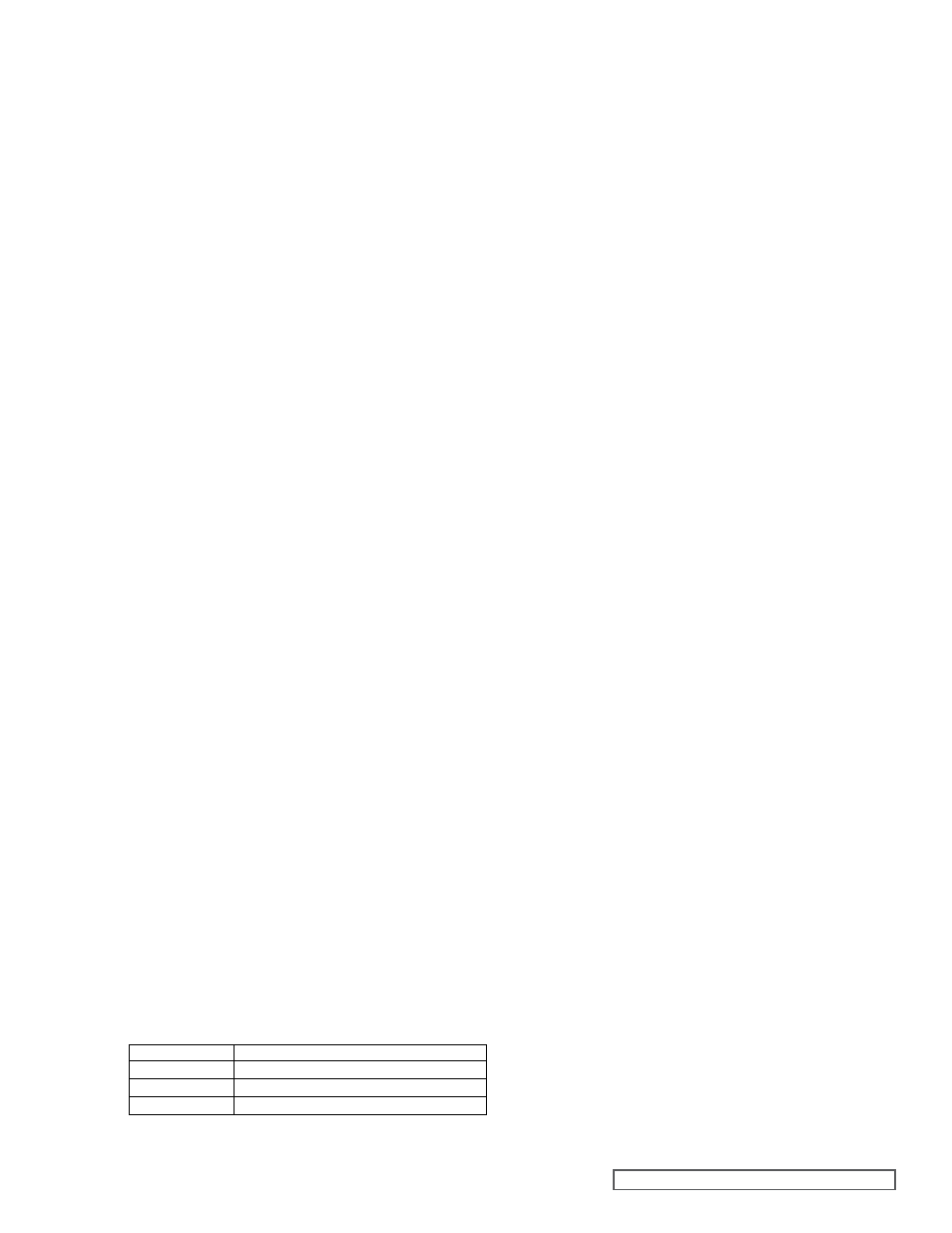

Standard catalog pumps require the following end clearance

settings.

Pump Size

Standard End Clearance (Inch)

N

.015

R

.020

P

.025

Pumps built for viscous liquid or high temperature service

may require extra end clearance. Each hole on the end

cap is about .004 inch additional end clearance. Consult

an authorized Viking distributor or the factory for further

information.

INSTAllATION Of CARbON

GRAPhITE bUShINGS

When installing carbon graphite bushings, extreme care

must be taken to prevent breaking. Carbon graphite is a

brittle material and easily cracked. If cracked, the bushing will

quickly disintegrate. Using a lubricant and adding a chamfer

on the bushing and the mating part will help with installation.

The additional precautions listed below must be followed for

proper installation.

1. A press must be used for installation.

2. Be certain the bushing is started straight.

3. Do not stop the pressing operation until the bushing is in

the proper position; starting and stopping will result in a

cracked bushing.

4. Check the bushing for cracks after installation.

Carbon graphite bushings with extra interference fits are

frequently furnished for high temperature operation. These

bushings must be installed by a shrink fit.

1. Heat the rotor bearing sleeve or idler to 750º F.

2. Install cool bushings with a press.

3. If facilities are not available to reach 750º F. temperature,

it is possible to install with 450º F. temperature; however,

the lower the temperature, the greater the possibility of

cracking the bushing.

Consult factory with specific questions on high temperature

applications. Refer to Engineering Service Bulletin ESB-3.