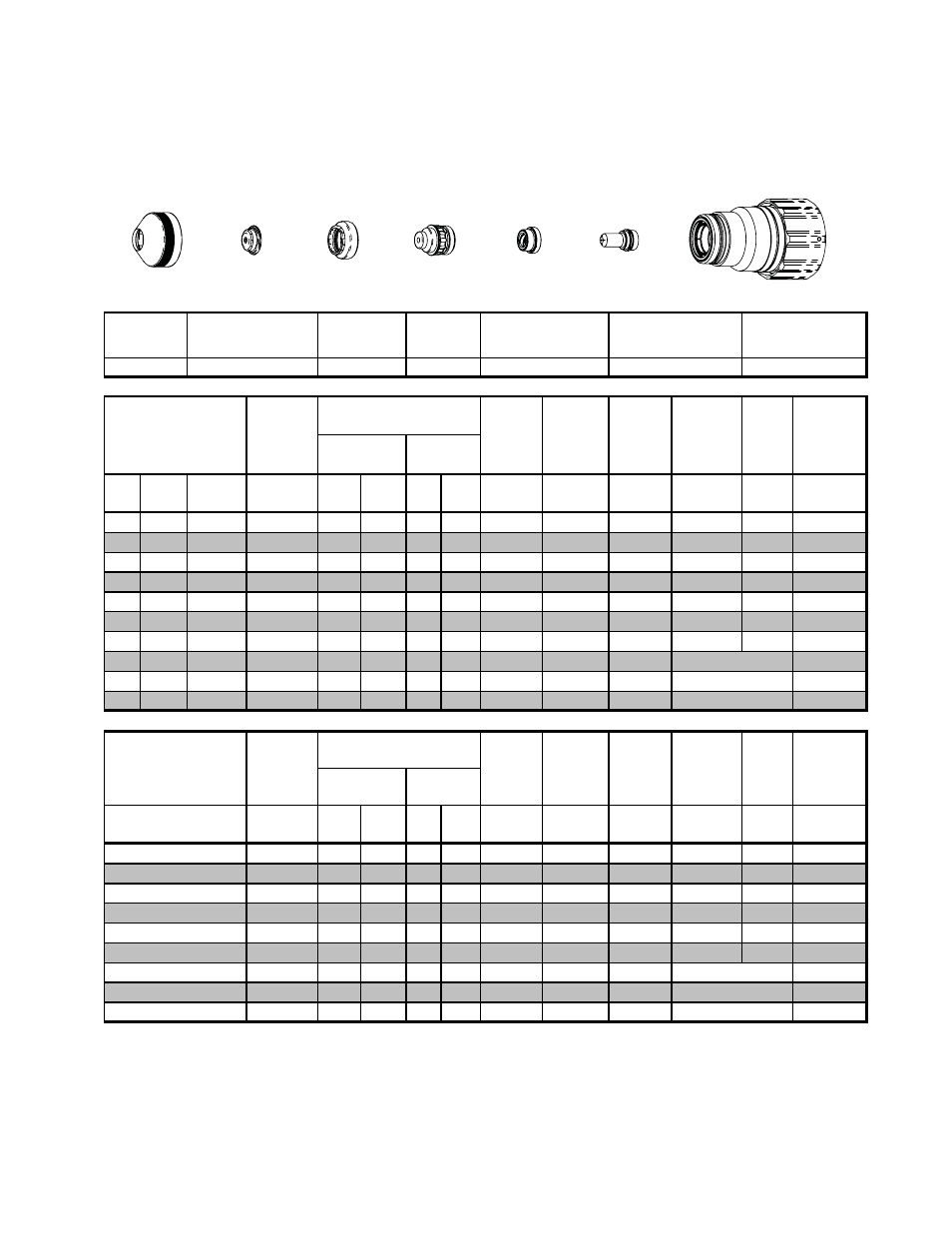

300a stainless steel n, Plasma / h, O shield – Tweco XT-301 Torch Data for Distributor use w- Auto-Cut 30O2 AE User Manual

Page 39

Manual 0-4831 Rev. AE

8-39

TORCH DATA for AutoCut O

2

(ga)

(in)

inch

psi

Ball

psi

Ball

psi

Volts

(in)

±0.005

(ipm)

(in)

(sec)

(in)

3/8

0.375

20

120

100

8

55

150

0.150

140

0.350

0.3

0.144

1/2

0.500

20

120

100

8

55

159

0.150

100

0.350

0.5

0.154

5/8

0.625

20

120

100

8

55

158

0.150

75

0.350

0.1

0.153

3/4

0.750

20

120

100

8

55

166

0.200

55

0.500

0.7

0.173

7/8

0.875

20

120

100

8

55

180

0.300

45

0.500

1.1

0.210

1

1.000

20

120

100

8

55

182

0.300

40

0.500

1.3

0.210

1 1/4

1.250

20

120

100

8

55

196

0.350

30

0.500

2.0

0.230

1 1/2

1.500

20

120

100

8

55

198

0.350

25

0.232

1 3/4

1.750

20

120

100

8

55

198

0.350

18

0.237

2

2.000

20

120

100

8

55

205

0.350

12

0.253

bar

Ball

bar

Ball

bar

Volts

(mm)

±0.1

(mm/min)

(mm)

(sec)

(mm)

1.4

120

6.9

8

3.8

151

3.8

3400

8.9

0.3

3.7

1.4

120

6.9

8

3.8

157

3.8

2760

8.9

0.5

3.9

1.4

120

6.9

8

3.8

158

3.8

2080

9.4

0.6

3.9

1.4

120

6.9

8

3.8

170

5.8

1320

12.7

0.8

4.7

1.4

120

6.9

8

3.8

182

7.6

1030

12.7

1.3

5.3

1.4

120

6.9

8

3.8

196

8.9

760

12.7

2.0

5.8

1.4

120

6.9

8

3.8

198

8.9

640

5.9

1.4

120

6.9

8

3.8

198

8.9

470

6.0

1.4

120

6.9

8

3.8

204

8.9

320

6.4

Pierce

Delay

Kerf Width

@ Rec.

Speed

Plasma (N

2

)

Shield

(H

2

O)

Arc

Voltage

Torch

Working

Height

Travel

Speed

Initial

Piercing

Height

Material

Thickness

Pre Flow

Pressure

(N

2

)

Cut Flow Rates /

Pressures

10

(mm)

Kerf Width

@ Rec.

Speed

Plasma (N

2

)

Cut Flow Rates /

Pressures

Arc

Voltage

Torch

Working

Height

Plasma Gas

Distributor

Electrode

Cartridge

Shield

Retainer

Shield Cap

Shield Gas

Distributor

Tip

35-1048

35-1089

35-1022

35-1015

35-1038

35-1284

35-1063

Edge Start

20

Travel

Speed

Initial

Piercing

Height

Pierce

Delay

Shield

(H

2

O)

15

Material

Thickness

Pre Flow

Pressure

(N

2

)

12

25

32

44

Edge Start

38

* Pressure of the water supply line should be regulated by customer pressure regulator.

Note1: Ohmic height sensing is not recommended with water shield. Water on the plate interferes electrically with the

ohmic sensing circuit.

Note2: Water source used for shield must be demineralized.

300A

Stainless Steel

N

2

Plasma / H

2

O Shield

BOLD TYPE indicates maximum piercing parameters. BOLD ITALIC indicates edge starts only.

Requires CCM version 3.4 or later. Requires GCM version 3.2 or later.

50

Edge Start

Edge Start

Edge Start

Edge Start

Cartridge

Electrode

Shield

Shield Gas

Distributor

Tip

Plasma Gas

Distributor

Shield Retainer

Art # A-07917_AC

This Art Is For Reference ONLY