Anti-spatter sprayer, 01 starting installation, 02 wiring the qrm-3 anti-spatter sprayer – Tweco QRM-3 Anti-Spatter Sprayer User Manual

Page 9

anti-spatter sprayer

2-5

SM-QRM-3

inStAllAtion And opeRAtion

10

1

5

8

2

6

7

11

3

4

9

SECTION 3:

INSTALLATION AND OPERATION

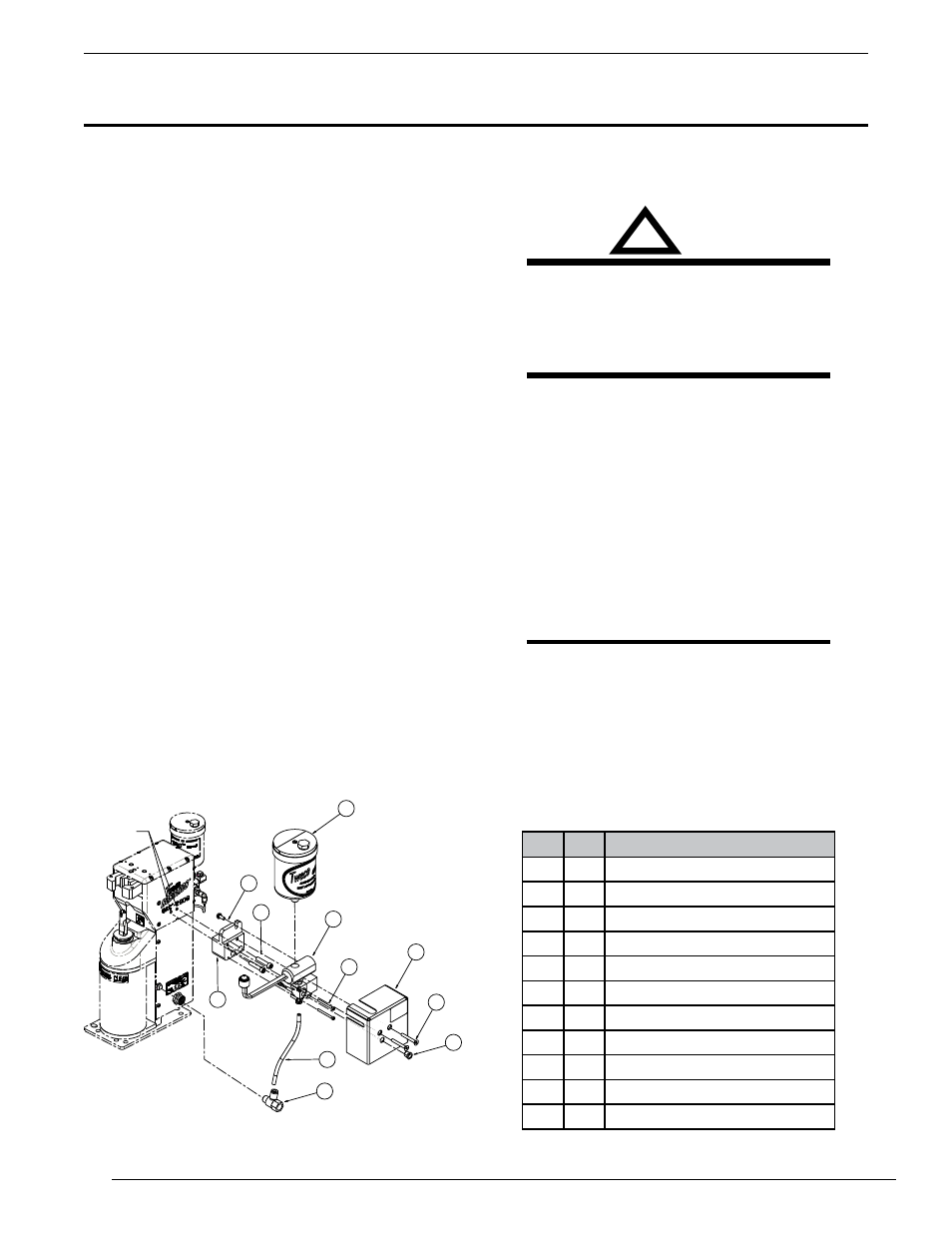

3.01 Starting Installation

The QRM-3 Anti-Spatter Sprayer was primarily designed

to be mounted at the right side of the Tweco

®

Robotics

QRC

TM

-2000 Nozzle Cleaning Station. It can also be

mounted in a variety of other convenient locations. For

best results, the sprayer should be installed within the weld

cell at a convenient location where the welding torch can

easily access. The QRC

TM

-2000 Nozzle Cleaning Station

has all the necessary mounting holes needed to install the

QRM-3 anti-spatter sprayer.

1. Attach the mounting block (#5) to the right side of the

QRC-2000 using two (2) 1/4-20 x 1.25” screws (#1)

(use Loctite).

2. Assemble the mister/valve sub-assembly (#8) onto

the mounting block with two (2) No.6-32x1.5” screws

(#7) (use Loctite).

3. Install 10-32 x1/2 screw (#10) with lock washer into

mister/valve sub assembly.

4. Screw the air fitting (#4) into the air intake port on the

QRC

TM

-2000.

5. Press one end of the 1/4” tubing (#9) into the air

fitting (#4) and the other end in to the bottom of the

sprayer/valve sub-assembly (#8).

6. Remove the red plug in the side of the sprayer/valve

sub-assembly. Place the cover (#6) over the sub-

assembly as shown and screw the exhaust port (#3)

into the hole on the side of the cover. Attach the cover

with (2) 10-32 x 11⁄2” counter-sunk screws. (#11).

No. Qty.

Description

1

2

1/4-20 X 1.25” SHCS

2

1

Reservoir

3

1

1/8-27 NPT Exhaust

4

1

Male-Female Tee Fitting

5

1

Mounting Block

6

1

Cover

7

2

6-32 X 1⁄2” Machine Screw

8

1

Sprayer/Valve Sub-Assembly

9

1

1/4” Poly Tubing 7” Long

10

1

10-32 X 1/2 HH w/ Lock Washer

11

2

10-32 X 1-1⁄2” C-Sunk Screw

Figure 2

3.02 Wiring the QRM-3 Anti-spatter

Sprayer

!

WARNING

Shut off poWeR befoRe connecting the WiReS

to the QRc-2000 ciRcuit boARd. do not SWitch

ciRcuit boARd SouRcing And Sinking SWitcheS

With poWeR on. dAMAge Will occuR. only Move

SWitcheS When the poWeR iS off.

Remove the shroud from the back of the QRC

TM

-2000

Nozzle cleaning station. Run the wires from the sprayer/

valve sub-assembly into shrouded area through a small

groove just under the mounting block. Measure the wires

to the circuit board, leaving an extra 2-3 in., and cut the

wires. Wire the QRM-3 as shown in the wiring diagram.

Replace the shroud back on to the unit with the wire placed

in the groove below the mounting block.

The drawings in Figure 3 show the QRM-3 wiring

connections.

NOTE

The color of QRM-3 leads does not make a

difference to which pins they go.

mounting

holes