Installation/setup transmig 2rt – Tweco 2RT Transmig User Manual

Page 19

INSTALLATION/SETUP

TRANSMIG 2RT

Manual 0-5196

3-3 INSTALLATION/SETUP

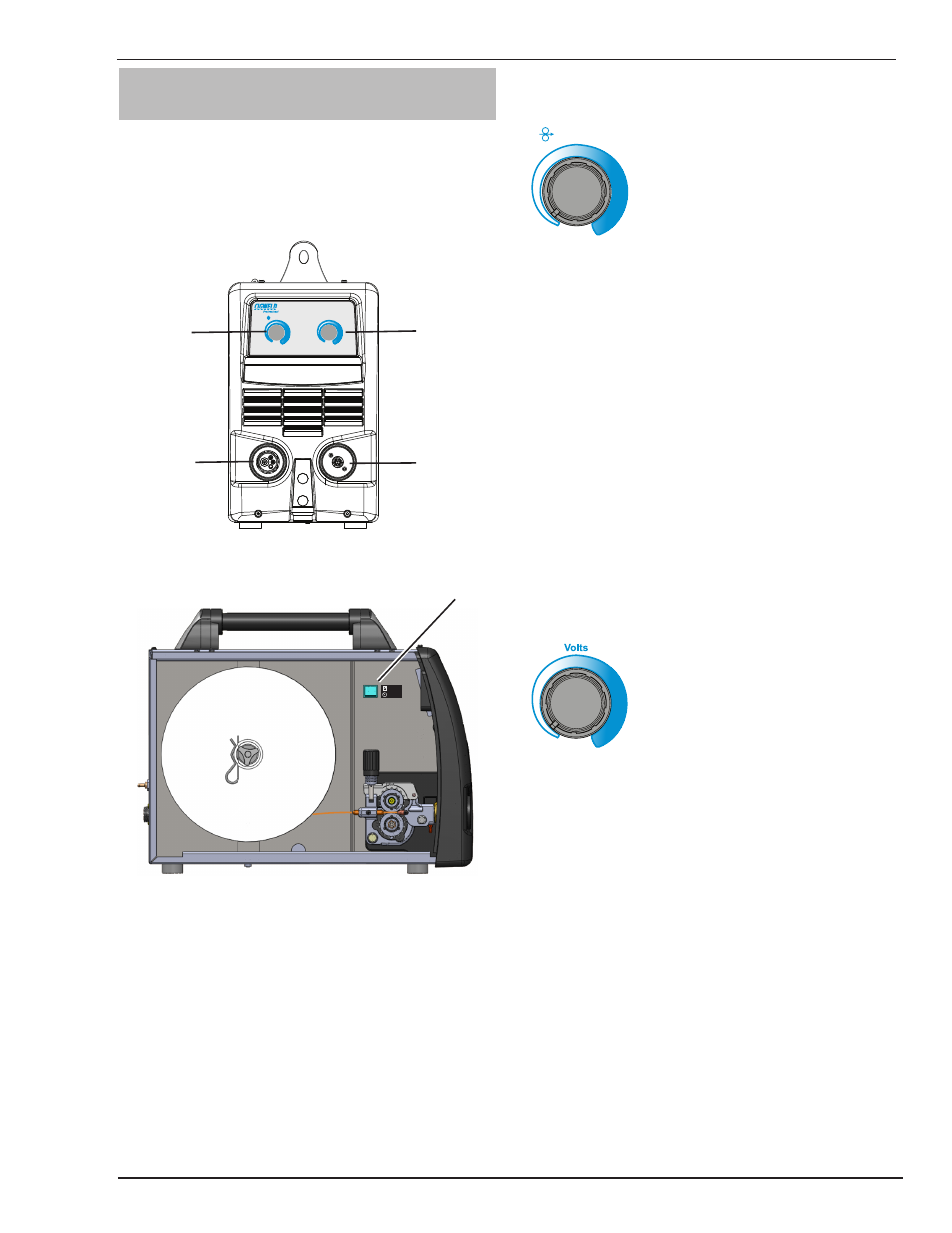

3.06 2RT Wire Feeder Controls,

Indicators and Features

The 2RT Wirefeeder is designed to be used with the

Transmig 250i. Select MIG Process and REMT in the

Advanced Features menu on the Transmig 250i to enable

the controls on the 2RT wirefeeder. See the 250i Operat-

ing manual for details.

Volts

Wirespeed

Left Knob

Right Knob

1

2

3

4

Art # A-10404

Figure 3-1: 2RT Front Panel Controls

Art # A-10470_AB

5

REMOTE

LOCAL

Figure 3-2: 2RT Local/Remote Switch

The Tweco professional MIG Torch will connect to the 2RT

just as it does to the 250i power source. The electrode

Polarity setting is done at the power source. See sub

sections 3.09 and 3.10.

1. Left Knob: WFS (Wire Feed Speed) Control

Amperage Control

Wirespeed

Left Knob

The Left Knob controls the Wirespeed in the wirefeeder.

It adjusts the preview wire speed display in the power

source. The amperage control knob adjusts the amount

of welding current delivered by the power source. In MIG

mode, the amperage knob adjusts the speed of the wire

feed motor (which in turn adjusts the output current by

varying the amount of MIG wire delivered to the welding

arc). The optimum wire speed required is dependent on

the type of welding application. The setup chart on the

inside of the wire feed compartment door of the Transmig

250i provides a brief summary of the required output set-

tings for a basic range of MIG welding applications. The

value may also be adjusted while a weld is in progress – if

this occurs, the left display will briefly switch to show the

adjusted value as the knob on the 2RT is turned, and will

automatically revert back to showing the set weld current

measurements when the knob is not being turned.

2. Right Knob: MIG Voltage Control

Right Knob

MIG Voltage Control

In this mode the control knob is used to adjust the output

voltage of the power source. It adjusts the preview volt-

age display in the power source. The welding voltage is

increased by turning the knob on the 2RT clockwise or

decreased by turning the knob anti-clockwise. The opti-

mum voltage level required is dependent on the type of

welding application. The setup chart on the inside of the

wire feed compartment door of the power supply provides

a brief summary of the required output settings for a basic

range of MIG welding applications. The value may also

be adjusted while a weld is in progress – if this occurs,

the left display on the power supply will briefly switch to

show the adjusted value as the knob on the 2RT is turned,

and will automatically revert back to showing the set weld

current measurements when the knob is not being turned.