Weldskill 100 inverter, 06 welding power source problems – Tweco 100 Weldskill User Manual

Page 38

weldskill 100 iNVeRTeR

5-6

March 3, 2008

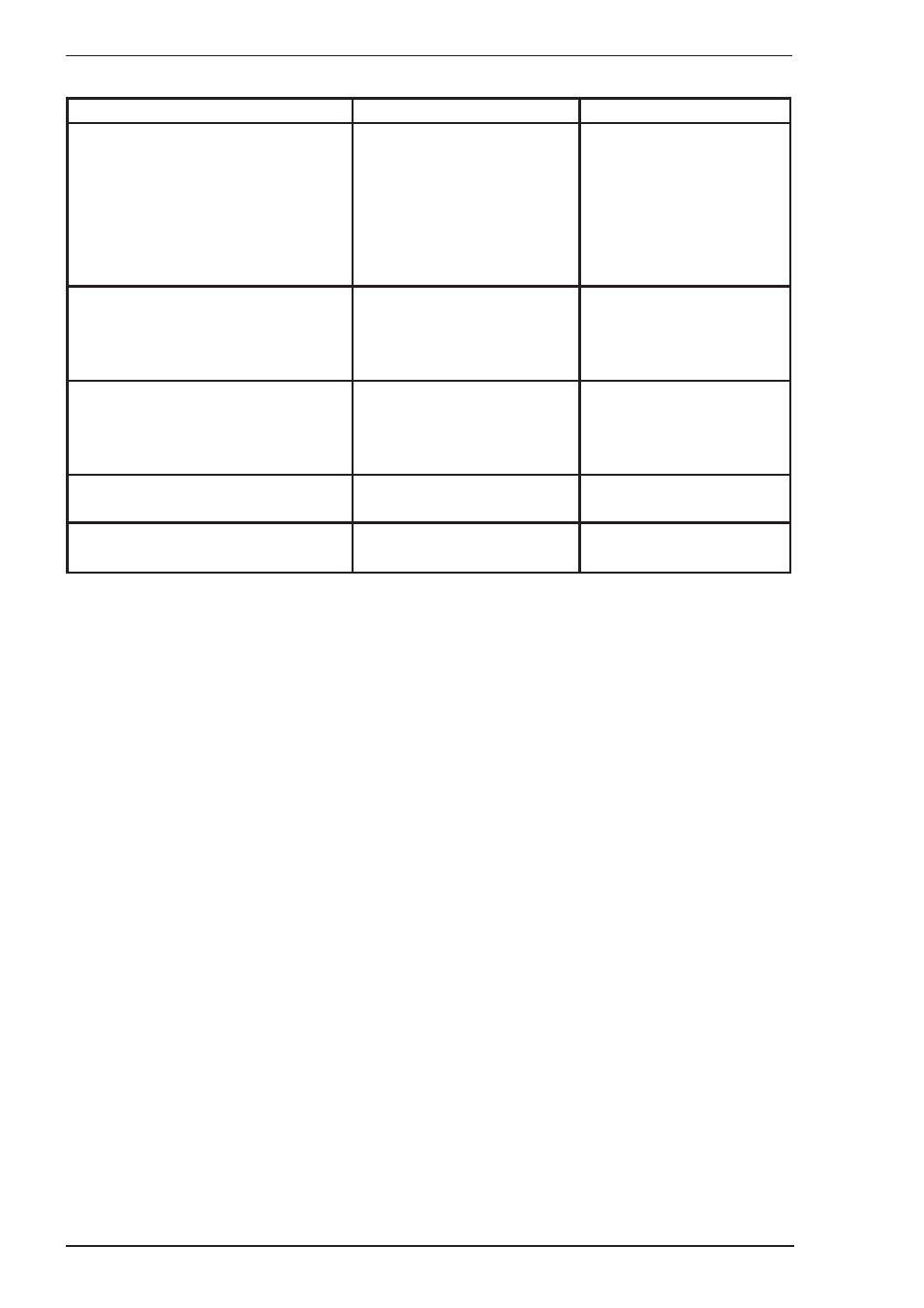

5.06 Welding Power Source Problems

Description

Possible Cause

Remedy

1 The welding arc cannot be

established

A The Primary supply voltage

has not been switched ON

A Switch ON the Primary

supply voltage

B The Welding Power Source

switch is switched OFF

B Switch ON the Welding

Power Source

C Loose connections internally

Have an Accredited

Cigweld Service Provider

repair the connection

2 Maximum output welding current

cannot be achieved with nominal

Mains supply voltage

Defective control circuit

Have an Accredited

Cigweld Service Provider

inspect then repair the

welder

3 Welding current reduces when

welding

Poor work lead connection to

the work piece

Ensure that the work lead

has a positive electrical

connection to the work

piece

4 TIG electrode melts when arc is

struck

TIG torch is connected to the

(+) VE terminal

Connect the TIG torch to

the (-) VE terminal

5 Arc flutters during TIG welding

Tungsten electrode is too

large for the welding current

Select the correct size of

tungsten elecrode