Tweco Raider 10,000 Pro User Manual

Page 18

20

local personnel and follow all applicable codes for safe

and proper installation.

Before the generator may be used to supply power, the

installer must first become familiar with and meet all

codes applicable to the installation of an auxiliary

generator. It is the installer's responsibility to follow the

applicable rules from the National Electrical Code (NEC),

state, local, and OSHA codes for the installation and use

of auxiliary power generators.

LOAD EVALUATION

Before connecting or operating the auxiliary power

generator, the installer must determine if the generator is

capable of supplying adequate power for a specific

application. Load and generator evaluation is essential for

satisfactory generator and equipment operation.

TYPES OF LOAD

Load requirements depend on the type of load connected

to the generator. There are two types of loads, resistive

and non-resistive. A resistive load, such as a light bulb,

requires a constant amount of power from the generator.

A non-resistive load, such as a portable grinder, requires

variable amounts of power from the generator. Because a

grinder requires more power for motor starting and is

rarely used with a constant, even pressure, the load

requirements can change greater than the operator

anticipates.

RUNNING LOAD REQUIREMENTS

The total running load applied to the generator is

calculated by adding up all the individual loads. Some

requirements are rated in amperes, others in watts. The

requirements for most equipment is provided on its

nameplate.

Example 1: If a drill requires 5 amperes at 115 volts,

calculate its running power requirements in watts.

VOLTS x AMPERES = WATTS

115V x 5A = 575W

Therefor, the individual load applied by the drill is 575

watts.

Example 2: If a light bulb is rated at 200 watts, the

individual load applied the light bulb is 200 watts. If

three 200 watt light bulbs are used with the drill from

example 1 add the individual loads to calculate total load.

(200W + 200W + 200W) + 575W = 1175W

Therefore the total load applied by the three light bulbs

and drill is 1175 watts.

Motor-starting Requirements

Starting amperage requirements are many times the

running amperage of the motor. Starting requirements

must be determined to assure that the generator is capable

of starting the motor without damaging it. This can be

done by examining the motor nameplate and identifying

the code letter specifying the starting kVA/HP required.

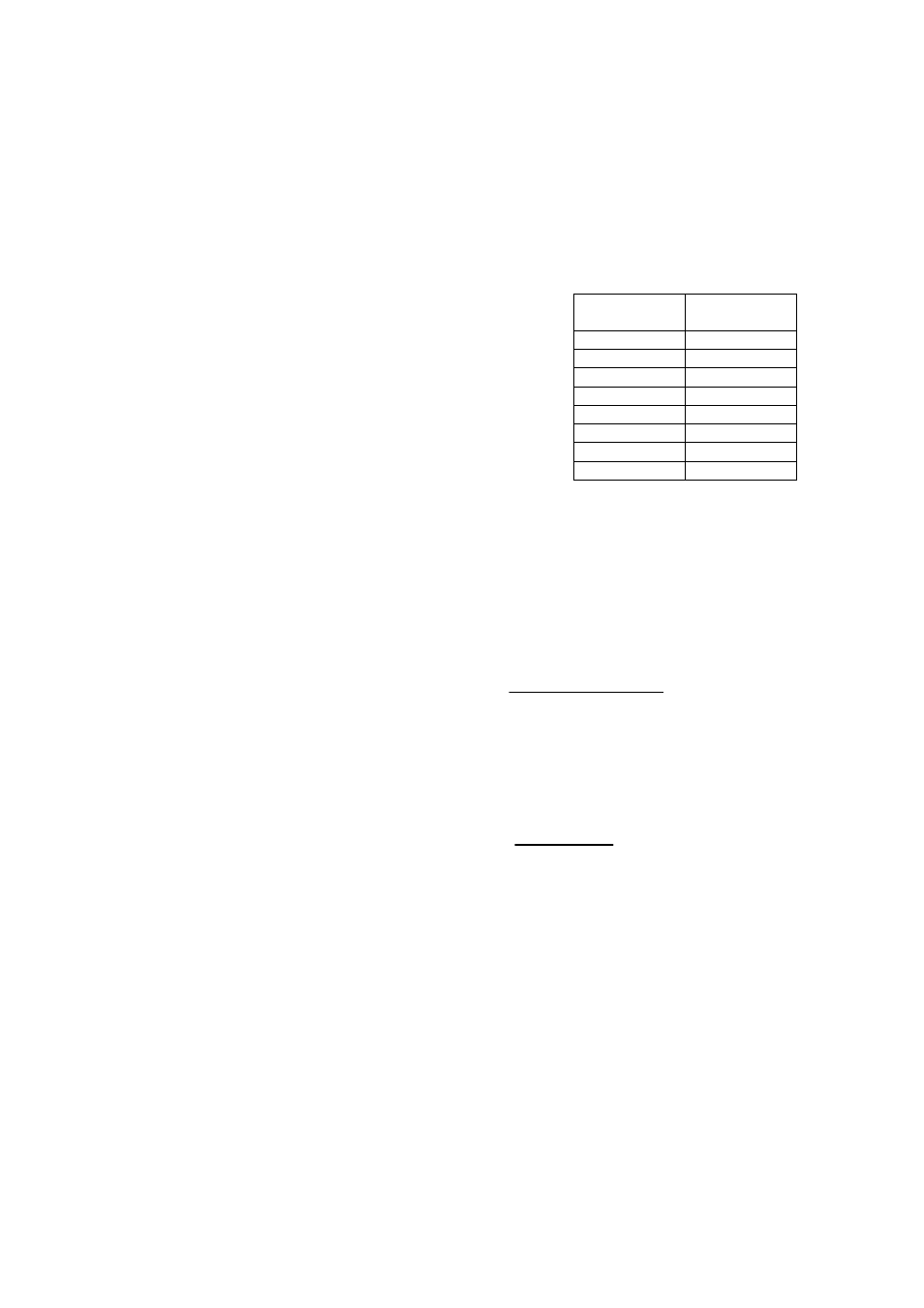

Motor Start

Code Leter

KVA/HP

G

6.3

H

7.1

J

8.0

K

9.0

L

10.0

M

11.2

N

12.5

P

14.0

If the kVA/HP requirement, motor horsepower, and

voltage rating are known, the starting amperage can be

calculated.

Example: Calculate the starting amperage required for a

230V, ¼ HP motor with a motor start code of G.

Equation

KVA/HP x HP x 1000

= STARTING AMPERAGE

VOLTS

Volts = 230

HP = ¼

Code G results in kVA/HP = 6.3

6.3 x ¼ x 1000

= 6.85A

230

Therefore, starting the motor requires 6.85 amperes.

If a code letter is not present on the motor nameplate,

approximate starting amperage is equal to six times

running amperage. This is a reasonable approximation for

all applications where the generator rated amperage is at

least twice the motor requirement. If the generator-to-

motor-size ratio is less than 2:1 acquire the needed

information to properly determine the motor-starting

requirement.

TECHNICAL SPECIFICATIONS