Service, Torch maintenance, Service -1 – Tweco PWH-M 2A User Manual

Page 23: Torch maintenance -1

Service

4-1

Manual 0-2005

SERVICE

The Service Section is divided into two parts:

4.1. Torch Maintenance

4.2. Torch Leads

4.1. TORCH MAINTENANCE

WARNING

Check to be sure the main disconnect to the weld-

ing system is open before disassembling the torch.

Torch Disassembly and Inspection

CAUTION

The electrode cap has an O-ring seal to prevent

gas leakage. It is important to observe the fol-

lowing precautions for the 0-ring:

A) Make sure that the groove and the surface that

the O-ring will seal against are clean and free

of nicks and scratches.

B) Check to see that the O-ring is not cut or cracked.

C) Lubricate O-ring with a light coating of Cat. No.

8-4025 O-ring lubricant. This should be used

sparingly, just enough to make the O-ring slip-

pery, but not enough to accumulate in the torch.

Disassemble the torch as follows:

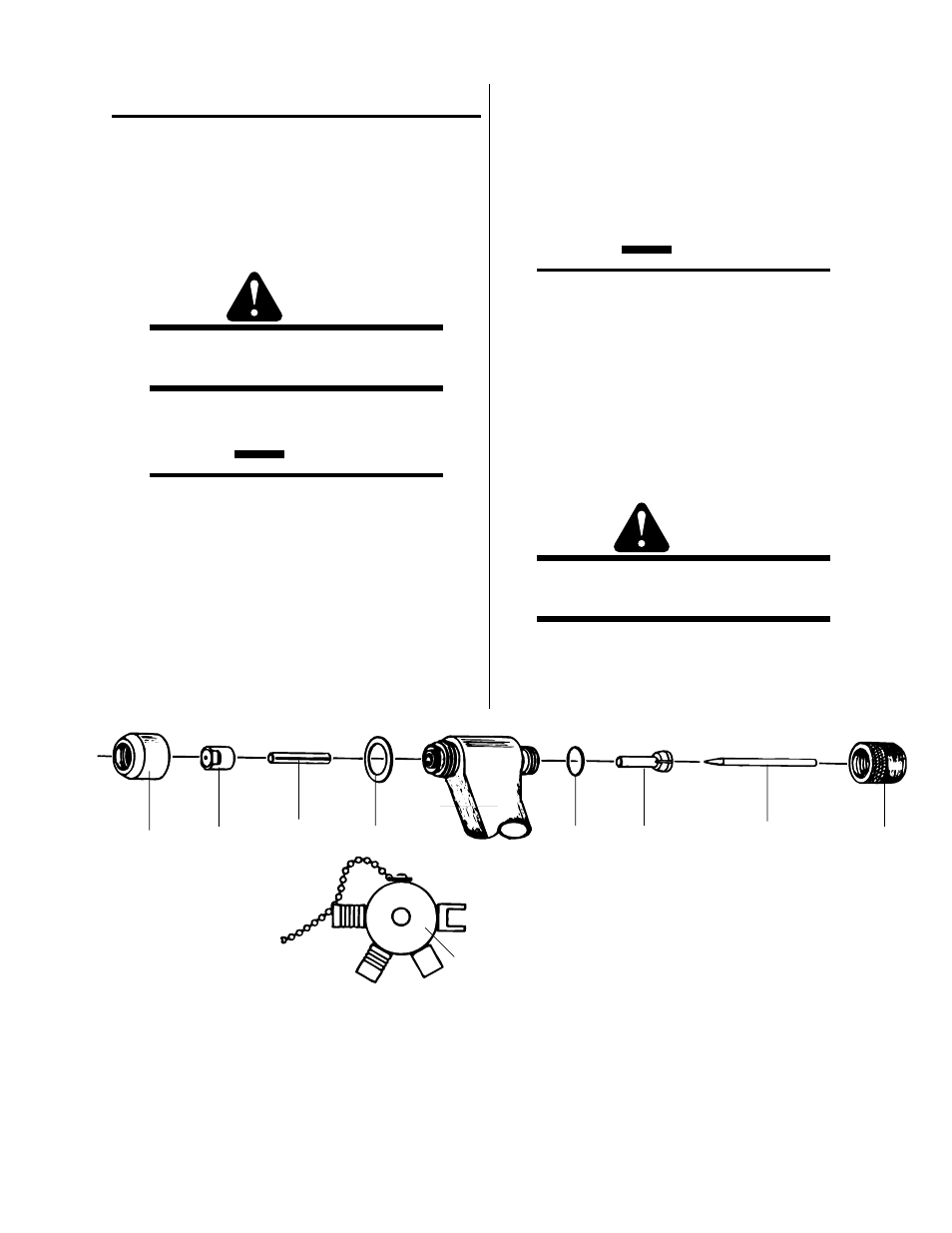

1) Unscrew the ceramic shield cup (1).

CAUTION

Hold the torch with the tip end up to prevent the

gas distributor from falling out and breaking.

2) Using the wrench (10), unscrew the tip (2).

3) Unscrew the electrode cap (9) while still hold-

ing torch tip end up. Slowly lower the cap until

the collet (7), and the electrode (8) can be

grasped with fingers. The gas distributor (3) will

come out with the electrode and collet.

Torch Assembly

WARNING

Primary power to the welding system must be

disconnected before assembling the torch.

1) Insert the electrode (8) in the collet (7) and then

this assembly into the rear of the torch head (5).

Hold in place with finger.

3

9

5

4

1

2

6

7

8

10

1.

Shield Cup

2.

Tip

3.

Gas Distributor

4.

Gasket

5.

Basic Head Assembly

6.

O-ring

7.

Collet

8.

Electrode

9.

Electrode Cap

10.

Wrench & Gage Assembly

Figure 4-A Torch Parts Explosion