09 internal controls and connections, 09 internal controls and connections -7, Portafeed vs 212 – Tweco VS 212 PortaFeed User Manual

Page 25

PORTAFEED VS 212

Manual No. 0-4994

2-7

INTRODUCTION

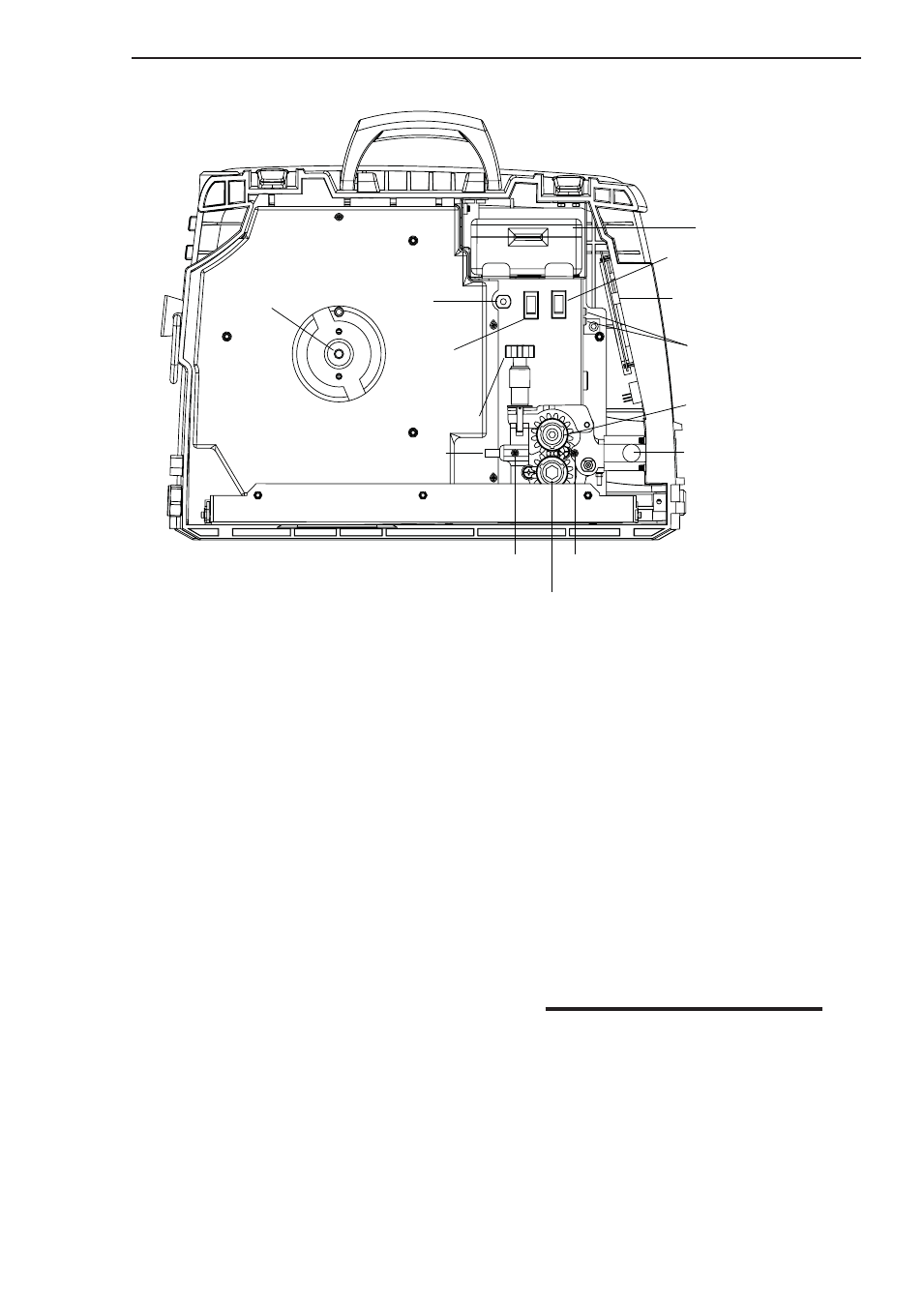

2.09 Internal Controls And Connections

1. STORAGE BOX: On the job storage for drive rolls,

tips, nozzels, etc. To remove, lift up to release

velcro and slide it up and over the side retainers.

2. HIGH/LOW RANGE SWITCH: Gives a finer dial

control over the wire speed, which is especially

useful with larger diameter flux-cored wires.

3. WIRE SPEED/AMP METER SELECTION DIP

SWITCHES: Set these switches to change the lower

meter display from wire speed to amperage output

of the power source. Refer to Section 2.08, item 3

and section 4.07 for DIP switch setting information.

4. CARTRIDGE GUN LEADS: These two spade

terminals provide the MIG gun switch connection.

5. UPPER RETAINING KNOB: This knob is used to

secure the bearing feed roll. Remove this knob to

change the bearing feed roll.

6. GUN CLAMP KNOB: Tighten this knob to secure

the welding gun to the wire feeder.

7. OUTPUT GUIDE LOCKSCREW: Tighten this screw

to secure the output wire guide.

8. LOWER RETAINING KNOB: This knob is used to

secure the drive feed roll. Remove this knob to

change the drive feed roll.

9. INPUT GUIDE LOCKSCREW: Tighten this screw

to secure the input wire guide.

10.INPUT WIRE GUIDE: This guide is required to

direct the welding wire from the wire spool to the

drive feed roll.

11.SPRING TENSION KNOB: Use the spring tension

knob to adjust the amount of force the bearing

feed roll exerts on the welding wire.

12.CC/CV MODE SWITCH: The CC position provides

a voltage sensing wire feed speed mode of

operation for use with constant current (CC) power

sources. The CV position provides a constant wire

feed speed mode of operation for use with constant

voltage (CV) power sources.

NOTE

This switch does not select a CC or CV mode

of operation. The mode of operation is set

by the type of power source being used.

13.INPUT CIRCUIT BREAKER: This circuit breaker

provides complete system protection for the wire

feeder in the case of a fault or overload condition.

14.HUB TENSION BOLT: The hub tension bolt is used

to adjust the wire spool tension which acts as a

mechanical brake to assist in the stopping of the

welding wire at the completion of a weld.

(14) HUB TENSION

BOLT

(13) INPUT CIRCUIT

BREAKER

(12) CC/CV MODE

SWITCH

(2) HIGH/LOW RANGE SWITCH

(11) PRESSURE ADJUST DEVICE

(5) UPPER RETAINING KNOB

(7) OUTPUT GUIDE LOCKSCREW

(6) GUN CLAMP KNOB

(8) LOWER RETAINING KNOB

(9) INPUT GUIDE LOCKSCREW

(10) INPUT WIRE GUIDE

Art # A-07138

(1) STORAGE BOX

(3) WIRE SPEED/AMP METER

SELECTION DIP SWITCHES

(4) CARTRIDGE GUN LEADS

High

Low

CC

CV

Figure 2-4: Internal Controls and Connections.