Tweco 300 TS Arcmaster(Feb2006) User Manual

Page 48

42

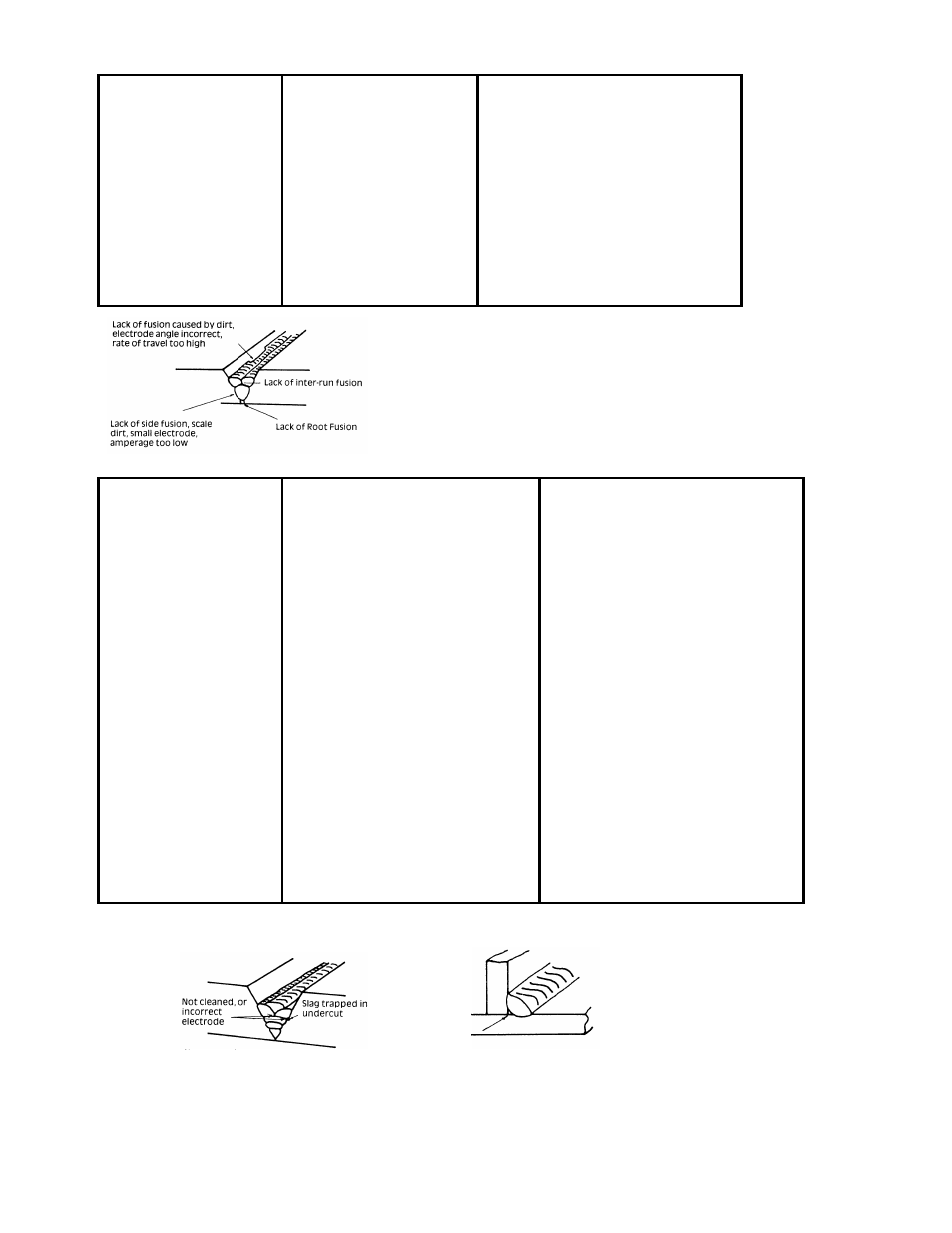

4 Portions of the weld

run do not fuse to the

surface of the metal

or edge of the joint.

A

B

Small electrodes used

on heavy cold plate.

Welding current is

too low.

A

B

Use larger electrodes and

pre-heat the plate.

Increase welding current.

C Wrong electrode angle. C Adjust angle so the welding arc is

directed more into the base metal.

D

Travel

speed

of

electrode is too high.

D Reduce travel speed of electrode.

E Scale or dirt on

joint surface.

E Clean surface before welding.

Figure 9. Example of Lack of Fusion

5 Non-metallic particles

are trapped in the

weld metal (slag

inclusion).

A Non-metallic particles may be

trapped in undercut from

previous run.

A If bad undercut is present, clean

slag out and cover with a run

from a smaller diameter electrode.

B Joint preparation too restricted.

B Allow for adequate penetration

and room for cleaning out

the slag.

C Irregular deposits allow slag

to be trapped.

C If very bad, chip or grind

out irregularities.

D Lack of penetration with slag

trapped beneath weld bead.

D Use smaller electrode with

sufficient current to give adequate

penetration. Use suitable tools to

remove all slag from corners.

E Rust or mill scale is preventing

full fusion.

E Clean joint before welding.

F Wrong electrode for position

in which welding is done.

F Use electrodes designed for

position in which welding is

done, otherwise proper control

of slag is difficult.

Figure 10. Examples of Slag Inclusion