Tweco 300 MST Arcmaster User Manual

Page 47

41

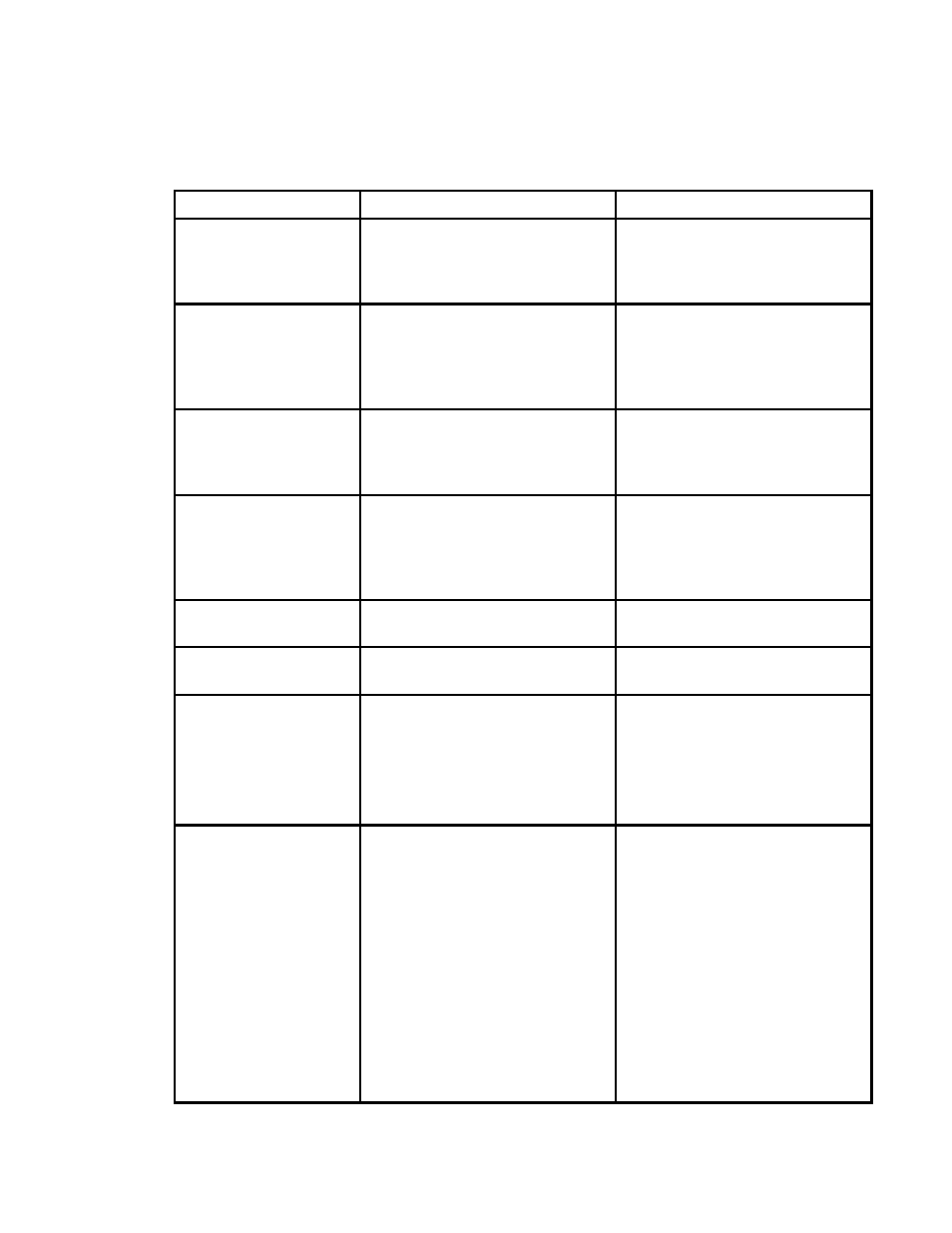

9.03 TIG Welding Problems

Weld quality is dependent on the selection of the correct consumables, maintenance of equipment and

proper welding technique.

Description

Possible

Cause

Remedy

1 Excessive beard build-

up or poor penetration

or poor fusion at edges

of weld.

Welding current is too low.

Increase weld current and/or faulty

joint preparation.

2 Weld bead too wide

and flat or undercut at

edges of weld

or excessive

burn through.

Welding current is too high.

Decrease

weld

current.

3 Weld bead too small or

insufficient penetration

or ripples in bead are

widely spaced apart.

Travel speed too fast.

Reduce travel speed.

4 Weld bead too wide or

excessive bead build up

or excessive penetra-

tion in

butt joint.

Travel speed too slow.

Increase travel speed.

5 Uneven leg length in

fillet joint.

Wrong placement of filler rod.

Re-position filler rod.

6 Electrode melts when

arc is struck.

Electrode is connected to the

‘+’ terminal.

Connect the electrode to the

‘

−’ terminal.

7 Dirty weld pool.

A Electrode contaminated through

contact with work piece or filler

rod material.

A Clean the electrode by grinding off

the contaminates.

B Gas contaminated with air.

B Check gas lines for cuts

and loose fitting or change

gas cylinder.

8 Electrode melts or

oxidizes when an arc is

struck.

A No gas flowing to

welding region.

A Check the gas lines for kinks

or breaks and gas

cylinder contents.

B Torch is clogged with dust.

B Clean torch

C Gas hose is cut.

C Replace gas hose.

D Gas passage contains impurities.

D Disconnect gas hose from torch

then raise gas pressure and blow

out impurities.

E Gas regulator turned OFF.

E Turn ON.

F Torch valve is turned OFF.

F Turn ON.

G

The electrode is too small for

the welding current.

G Increase electrode diameter or

reduce the welding current.