Tweco 300 MST Arcmaster User Manual

Page 31

25

ii) Vertical up welding

When welding vertical up with arc force on, the operator can control the amount of

current by changing arc length, ie voltage. Weld metal is deposited by “digging” the

electrode into the side of the base metal joint and then increasing the arc length with a

flicking motion, to allow the weld pool to freeze, before digging the electrode into the

other side of the base metal joint.

Without arc force, increasing the arc length does not decrease the weld current

sufficiently and the operator has to manually decrease the current via a remote current

control to freeze the weld pool. This welding current reduction also reduces the

penetration.

The arc force allows the weld pool to freeze during the “flick” phase without decreasing the amount of

weld current available during the “dig” phase thus maximizing penetration.

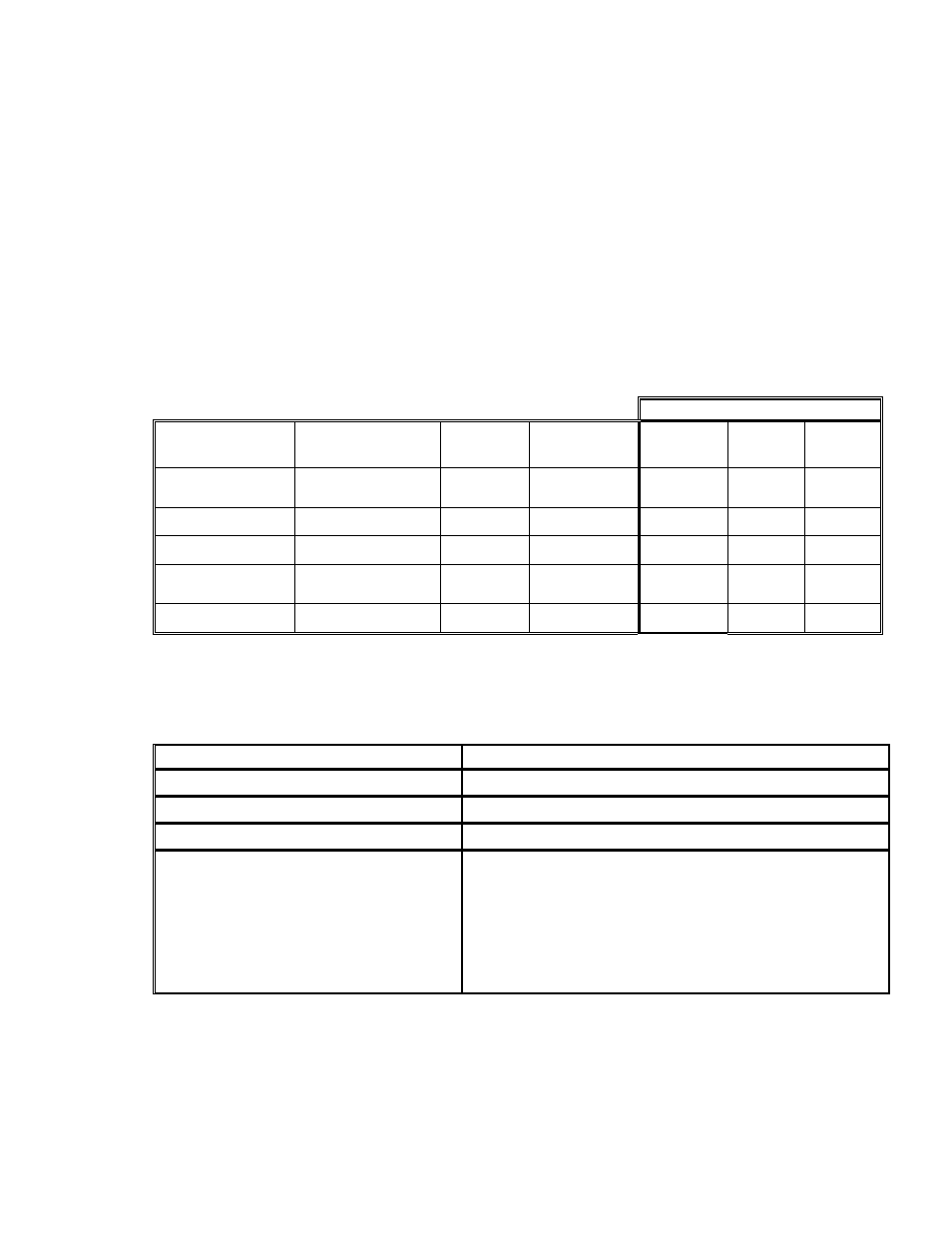

3.05 Weld Parameters

Weld

Mode

Weld

Parameter

Parameter Range

Factory

Setting

Incremental

Unit

STICK

MIG

LIFT TIG

WELD (V)

MIG

10.0 to 32.0V DC

17.0V

0.1V

INDUCTANCE

0 to 100%

10%

1%

HOT START

0 to 70A

20A

1A

WELD (A)

TIG or STICK

5 to 300A DC

80A

1A

ARC CONTROL

0 to 100%

10%

1%

Table 6 – Weld Parameters

3.06 Power Source Features

Feature Description

New Digital Control

•

All welding parameters are adjustable

Touch Panel Switches

•

Touch switches eliminate mechanical damage

Front Control Cover

•

Protects front panel controls

Digital Meter Volt & Ammeter

•

Displays selected weld parameter value

•

Displays average weld current when welding

•

Displays average weld current for 20 seconds after weld

has been completed

•

A selected weld parameter value can be adjusted at any

time even while welding