07 machine torch operation, 07 machine torch operation -5, 06 servicing machine torch components – Tweco Max 300 w-Merlin 6000 User Manual

Page 35

Manual 0-2573

5-5

SERVICE

E. Erratic or improper cutting output

1. Poor input or output connections to power supply

a. Check all input and output connections.

2. Current set too low at power supply

a. Increase current setting.

3. Torch is being moved too fast across workpiece

a. Reduce cutting speed (refer to Appendix 2, Cut-

ting Speed Charts).

4. Excessive oil or moisture in torch

a. Hold torch 1/8 inch (3 mm) from clean surface

while purging and observe oil or moisture

buildup (do not activate torch)

F. No gas flow

1. Gas not connected or pressure too low

a. Check source for at least 90 psi (6.2 bar).

2. Faulty components in torch and leads assembly

a. Inspect torch assemblies and replace if neces-

sary. Refer to Section 5.07, Torch and Leads

Troubleshooting.

3. Faulty components in power supply system components

a. Return for repair or have qualified technician

repair per Service Manual.

G. Torch cuts but not adequately

1. Current set too low at power supply

a. Increase current setting

2. Improper plasma or secondary gas selected for application

a. Refer to Cut Quality, Section 4.05-H

3. Torch is being moved too fast across workpiece

a. Reduce cutting speed (refer to Appendix 2, Cut-

ting Speed Charts).

4. Excessive oil or moisture in torch

a. Hold torch 1/8 inch (3 mm) from clean surface

while purging and observe oil or moisture

buildup (do not activate torch)

5. Torch tip contacting workpiece

a. Increase standoff distance

6. Torch tip worn

a. Replace tip

7. Incorrect gas pressure

a. Set correct gas pressure

5.06 Servicing Machine Torch

Components

WARNINGS

Disconnect primary power to the system before

disassembling the torch or torch leads.

DO NOT touch any internal torch parts while the

AC indicator light on the front panel of the Power

Supply is ON.

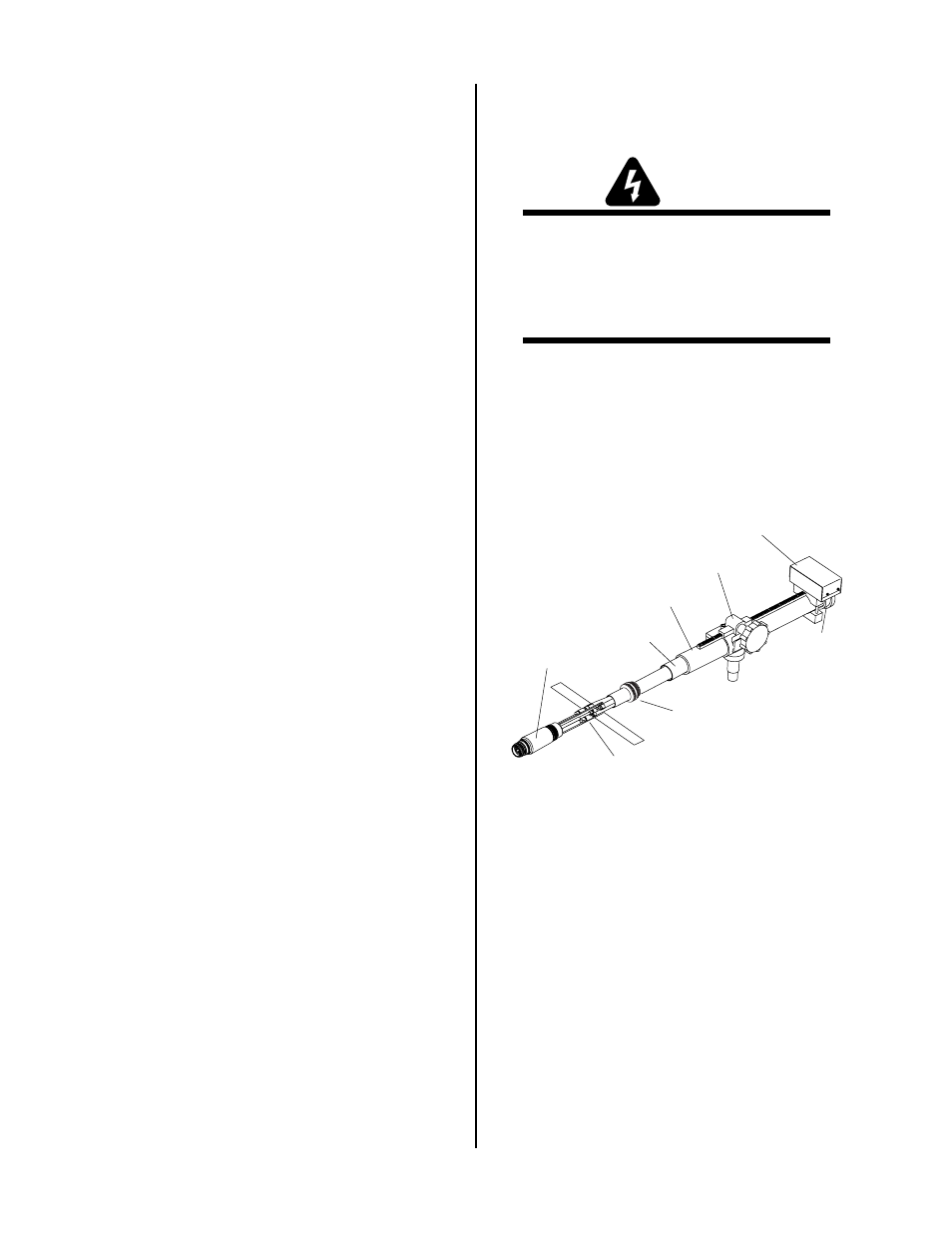

A. Removing Machine Torch Head

1. Remove the shield cup, tip, gas distributor and

electrode from the torch head assembly.

2. Unscrew the positioning tube from the torch

adapter on the torch head assembly and slide the

positioning tube up the leads.

Positioning Tube

Torch Adapter

Lead Connections

A-02002

Bushing

Pinion Assembly

Machine

Torch Head

Insulator

Gas Control Assembly

Figure 5-5 Torch Mounting Assembly

3. Disconnect the plasma, secondary (+), coolant

supply and coolant return (-) fitting connections.

Note the location of the torch leads insulator

which separates the negative and positive leads.