08 recommended cutting speeds – Tweco Max 300 w-Merlin 6000 User Manual

Page 29

Manual 0-2573

4-7

OPERATION

C. Piercing With Machine Torch

To pierce with a machine torch, the arc should be

started with the torch positioned as high as possible

above the plate while allowing the arc to transfer and

pierce. This standoff helps avoid having molten metal

blow back onto the front end of the torch.

When operating with a cutting machine, a pierce or

dwell time is required. Torch travel should not be

enabled until the arc penetrates the bottom of the

plate. As motion begins, torch standoff should be

reduced to the recommended 1/8 - 3/8 inch (3 - 10

mm) distance for optimum speed and cut quality.

A standard shield cup is recommended for most ma-

chine cutting applications. Do not allow an exposed

torch tip to contact the workpiece.

Piercing the plate is not recommended on plates hav-

ing a thickness greater than 1 inch (25.4 mm). Blow-

back from the piercing operation can shorten the life

of torch parts. All piercing should therefore be done

as quickly as possible and at maximum amperage and

maximum standoff.

Pierce off the cutting line and then continue the cut

as needed. Clean spatter and scale from the shield

cup and the tip as soon as possible. Spraying or dip-

ping the shield cup in anti-spatter compound will

minimize the amount of scale which adheres to it.

This can significantly increase shield cup life.

4.08 Recommended Cutting Speeds

Cutting speed depends on material, thickness, and the

operator’s ability to accurately follow the desired cut line.

The following factors may have an impact on system per-

formance:

• Torch parts wear

• Air quality

• Operator experience

• Torch standoff height

• Proper work cable connection

• Alloy content of material

NOTE

This information represents realistic expectations

using recommended practices and well-maintained

systems. Actual speeds may vary from those shown

in the charts depending on the alloy content of the

selected material.

For complete cutting speed chart data refer to Appendix

2.

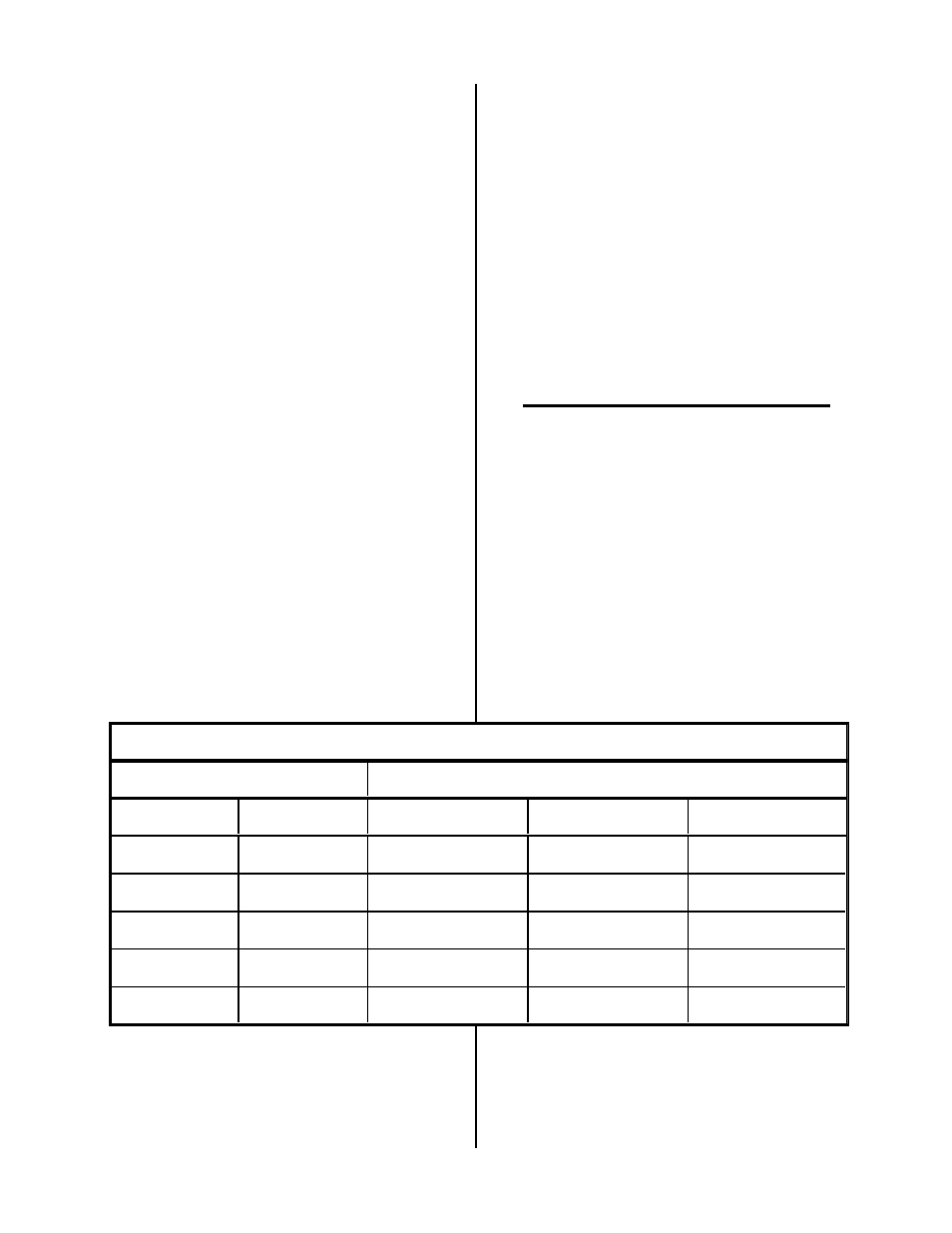

Characteristics of Recommended Gases for Plasma Arc Gouging

Type of Gas

Type of Material

Plasma

Secondary

Carbon Steel

Stainless Steel

Aluminum

Air

Air

Excellent

Good

Fair

Nitrogen

Air

Good

Good

Fair

Nitrogen

CO2

Good

Good

Good

Ar/H2

Nitrogen

Good

Excellent (Over 3/4 in)

Excellent

Ar/H2

Argon

Good

Excellent

Excellent