04 sequence of operations – Tweco GCM-6000 Gas Control User Manual

Page 27

Manual 0-2641

21

OPERATION

1

2

4

3

A-02381

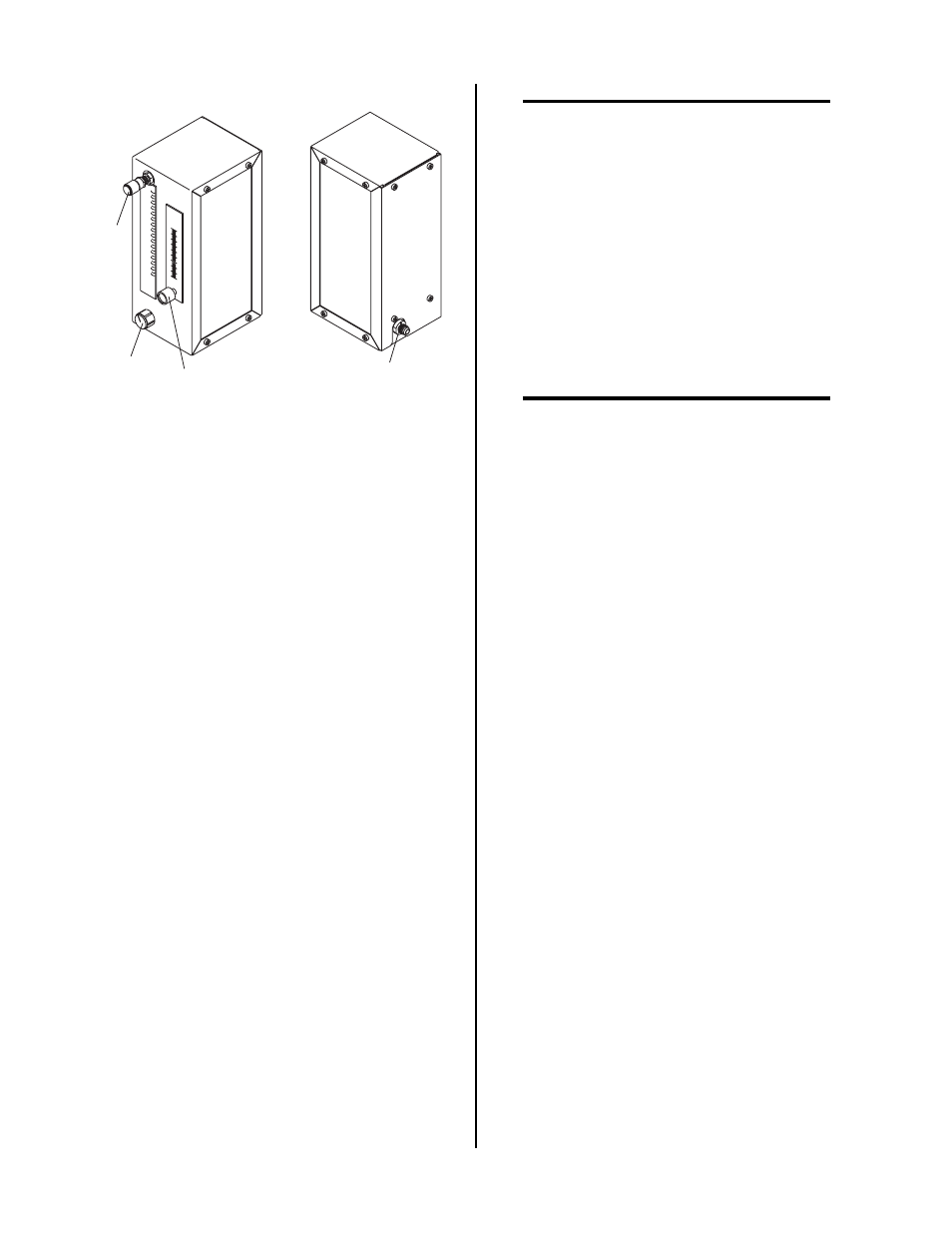

Figure 4-3 Optional Secondary Gas/Water Flow

Control

4.04 Sequence Of Operations

This Subsection contains four Sequence Of Operations

that can be performed using the Gas Control Module with

or without the Optional Secondary Gas/Water Flow Con-

trol. The Sequence of Operations are listed in seperate

paragraphs as follows:

A. Operations Without Optional Gas/Water Flow

Control

B. Operations With Optional Gas/Water Flow Con-

trol, using CONVENTIONAL PLASMA process

(i.e. non-Square Cut)

C. Operations With Optional Gas/Water Flow Con-

trol Using Gas Secondary Flow Control.

D. Operations With Optional Gas/Water Flow Con-

trol Using Secondary Water

Depending on the application and the equipment in-

stalled refer to the desired Sequence of Operation.

A. Operations Without Optional Gas/Water

Flow Control

1. Connect the required gas supplies to the correct plasma

and secondary inlets on the Master Power Supply.

Refer to the Master Power Supply Operating Manual,

0-2652, to make connections.

2. Turn ON the gas supplies.

3. Set the gas bottle regulators, if used, to the proper pres-

sure and check for leaks.

NOTE

While nothing prevents the operator from switch-

ing gases during piloting or cutting it is not rec-

ommended to do so. It may cause pressure or flow

fluctuations that may damage torch parts or the

piece being cut.

4. Refer to the Operating Manual supplied with the Power

Supply and turn ON power to the Power Supply.

5. Select the desired plasma and secondary gases by set-

ting the Gas Control Module front panel switches to

the desired gas positions.

6. To set the preflow gas pressure and flow rate do the

following (see NOTE):

NOTE

Preflow is set only when using oxygen (O

2

) plasma

gas. For all other plasma gases DO NOT do this

step.

a. Set the MODE switch to PILOT SET.

b. Fully open the valve on the top of the PREFLOW

flowmeter.

c. Pull out the knob on the PREFLOW regulator.

d. Turn the knob clockwise to increase or counter-

clockwise to decrease gas pressure.

e. Push the knob back in to lock the pressure setting.

f. Slowly close the valve on the top of the PREFLOW

flowmeter until the desired flow rate is achieved.

7. To set the plasma gas pressure and flow rate do the

following:

a. Set the MODE switch to PLASMA SET.

b. Fully open the valve on the top of the PLASMA

flowmeter.

c. Pull out the knob on the PLASMA regulator.

d. Turn the knob clockwise to increase or counter-

clockwise to decrease gas pressure.

e. Push the knob back in to lock the pressure setting.

f. Slowly close the valve on the top of the PLASMA

flowmeter until the desired flow rate is achieved.

8. To set the secondary gas pressure do the following:

a. Set the MODE switch to SEC SET.

b. Pull out the knob on the SECONDARY regulator.

c. Turn the knob clockwise to increase or counterclock-

wise to decrease gas pressure.

d. Push the knob back in to lock the pressure setting.