Section 3 torch: installation, 3t.01 torch connections, 3t.02 setting up mechanical torch – Tweco 25mm Cutmaster User Manual

Page 29: Section 3 torch, Installation t-1, Cutmaster 25mm

CUTMASTER 25MM

Manual 0-5080

INSTALLATION

3T-1

SECTION 3 TORCH:

INSTALLATION

3T.01 Torch Connections

If necessary, connect the torch to the Power Supply.

Connect only the Victor Thermal Dynamics model SL60

/ Manual or SL100 / Mechanical Torch to this power

supply. Maximum torch leads length is 100 feet / 30.5

m, including extensions.

WARNING

Disconnect primary power at the source be-

fore connecting the torch.

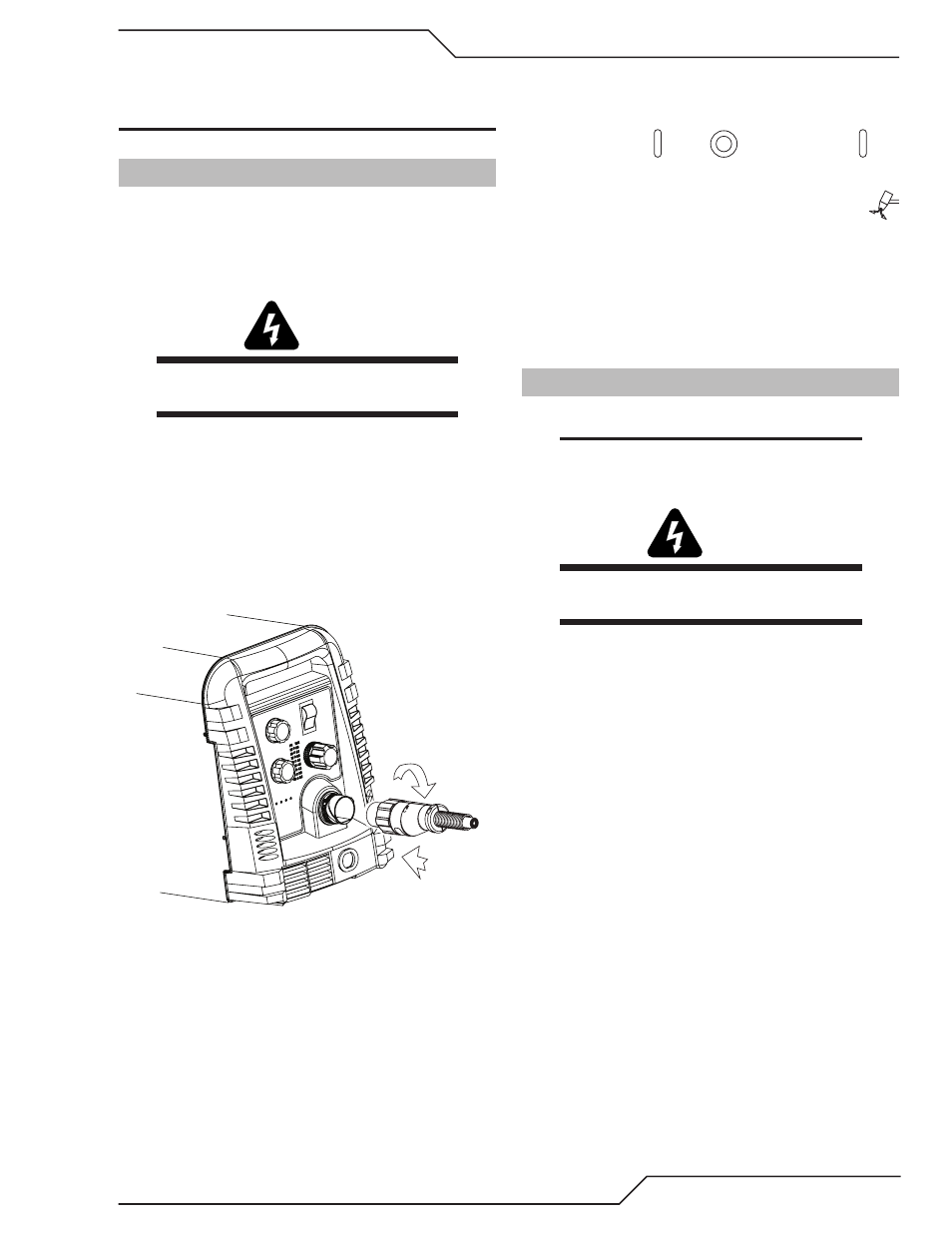

1. Align the ATC male connector (on the torch lead)

with the female receptacle. Push the male con-

nector into the female receptacle. The connectors

should push together with a small amount of

pressure.

2. Secure the connection by turning the locking nut

clockwise until it clicks. DO NOT use the locking

nut to pull the connection together. Do not use

tools to secure the connection.

1

2

Art # A-07885

Connecting the Torch to the Power Supply

3. The system is ready for operation.

Check Air Quality

To test the quality of air:

1. Put the ON / OFF

switch in the ON (up)

position.

2. Put the Function Control switch in the SET

position.

3. Place a welding filter lens in front of the torch

and turn on the air.

Do not start an arc!

Any oil or moisture in the air will be visible on the

lens.

3T.02 Setting Up Mechanical Torch

NOTE

An adapter is required to be installed in the

power supply if converting a hand torch

system to operate a machine torch.

WARNING

Disconnect primary power at the source be-

fore disassembling the torch or torch leads.

The mechanical torch includes a positioning tube with

rack and pinch block assembly.

1. Mount the torch assembly on the cutting table.

2. To obtain a clean vertical cut, use a square to

align the torch perpendicular to the surface of

the workpiece.