Triton EPA 001 User Manual

Page 5

8

9

GB

GB

screws and relocate the front and rear angle stops

up or down their slots until the blade is square, then

re-tighten.

Loosen the height adjustment knobs and lower the

chassis until the top of planer blade is level with

the table. The best way is to place a flat board on

the table and adjust the chassis until the top of the

blade just touches the underside of the board

(Fig. 22).

Ensure that the chassis is level by measuring up

from the square tubes to the top of the height

brackets (Fig. 23). Independently adjust both ends

of the chassis until an equal reading is reached at

both ends. Re-check that the blade is still flush with

the table and make adjustments if necessary.

Apply the Scale Labels (29) to the height brackets.

Peel the ‘Front’ label from its backing and insert it

under the front scale indicator (nearest to the front

shoe of the planer). Align ‘0’ to the top edge of the

indicator and press into place, wrapping it around

the fold in the bracket (Fig. 24). Apply the rear label.

Return the planer to full height.

Fit the Pressure Fingers (30) to the height brackets

using the short Coach Bolts (17), Springs (31),

Washers (7) - fitted at each end of the springs, and

Nyloc nuts (26) (Fig. 25). They should both point

inward toward the planer (see also Fig. 27).

Tighten the nut until the bolt just protrudes through

it.

The tighter the nut, the greater the tension of the

pressure finger. Adjust the tension as required after

you have performed some cuts.

The pressure fingers can be easily re-located to any

of the four pre-set positions, or angled outwards

when not required. Pull the pressure finger outward

to disengage the locating pins then slide and/or

rotate it to the desired position (Fig. 26).

Loosen the plastic wing nut on the Planer Guard

Assembly (32) and insert it fully into the front

chassis tube. Retract the guard and tighten the

wing-nut to secure it in place (Fig. 27).

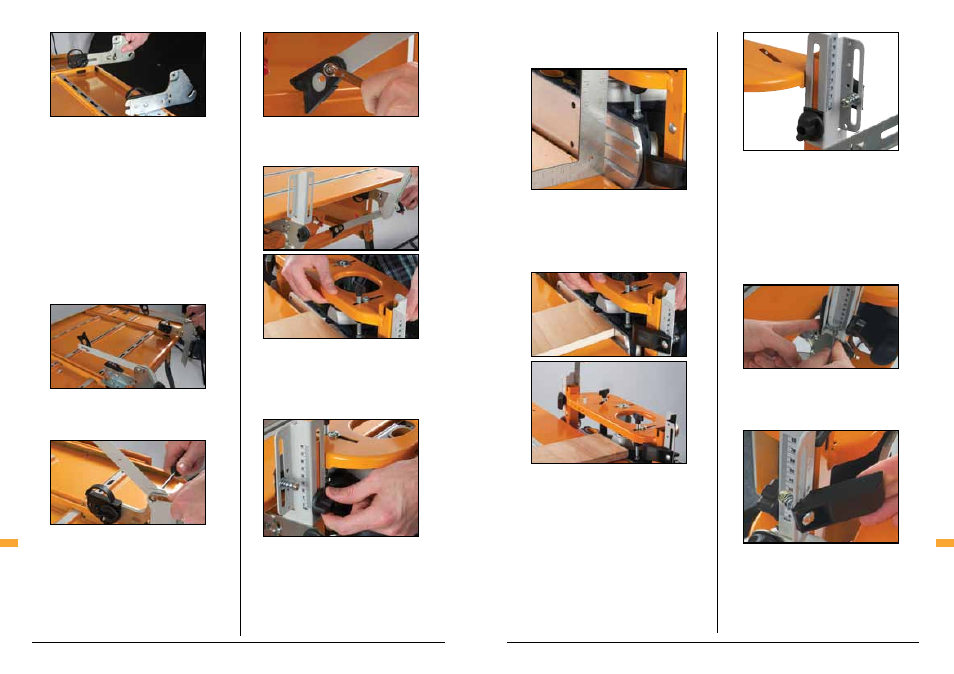

Insert the Front and Rear Pivot Brackets (21 and

22) between the plastic and steel components of

the table brackets and push until the steel tabs and

notches engage (Fig 14). Note: these parts may

be already pre-assembled. The small plastic stops

must face inward, toward each other. Tighten the

knobs.

Fit the Brace Struts (25) and Front and Rear Height

Brackets (23 and 24) to the inside face of the pivot

brackets using short M6 Screws (12), Nyloc Nuts

(26) and Washers (7) (Figs. 15 and 16). The bolts

prefitted to the height brackets locate in the slots

on the pivot brackets. Two washers are used at

each end - against the nut and inserted between

the height adjustment bracket and brace strut (Fig.

16).

Fit the brace with holes in it at the end furthest

away from the table T-slots and fit both braces with

the plastic toggles facing away from the T-slots

(Fig 15).

Turn the table over and re-fit to the Workcentre.

Ensure the table brackets are fully located and

tightened. Locate the braces with the toggles

resting on the Workcentre base channel (Fig. 17).

Loosen the nuts and adjust the toggle positions

until the braces 'snap' down into place (Fig. 17)

(inset).The correct position should support the table

without lifting it. Re-tighten the nuts.

Fit Round Knobs (18) to the front and rear height

adjustment brackets and lock them tilted outward

slightly, for easy mounting of the planer chassis

(Fig. 18).

Slide the planer chassis down between the

brackets and insert a long Coach Bolt (27), as

shown, through the square tubes at each end while

supporting the chassis (Fig. 19).

Fit the Height Indicators (28) and Round Knobs (18)

to the coach bolts (Fig. 20).

Lift the chassis to full height and tighten the round

knobs. Loosen the pivot knobs and pivot the

chassis vertical to the table then tighten

(Fig. 21).

Use a square to check that the planer blade is 90˚

to the table, as shown. If necessary, loosen the

Assembly

Assembly

Fig. 14

Fig. 15

Fig. 16

Fig. 17

Fig. 18

Fig. 19

Fig. 20

Fig. 21

Fig. 22

Fig. 23

Fig. 24

Fig. 25

Fig. 26