Triton EPA 001 User Manual

Page 4

6

7

GB

GB

Fit the Handle Clamp (15) to the handle bracket

using the short M6 Screws (12), Washers (7), and

M6 Flange Nuts (14). Pull the handle clamp up and

across until it firmly surrounds the planer handle,

then tighten into position (Fig. 8).

Tighten the rear clamp half to one turn to push

the planer handle snugly into the clamp assembly.

Check that there is no free movement of the handle,

and repeat the above steps if necessary.

Place a straight edge across the base of the rear

shoe, to check it is level with the chassis (Fig. 9).

There should be a 2-3mm gap between the straight

edge and either side of the chassis. Ensure the gap

is identical on either side by adjusting the position

of the rear and front clamps.

With your planer shoes still set exactly in line use

a straight edge down the length of the chassis and

measure from the square tubes at each end of the

chassis to check that the planer is parallel (Fig. 10).

The reading at the rear should be equal or 1-2mm

less than the front, but should never be greater.

Make adjustments to the handle bracket assembly

(repeat Fig’s 7 and 8) until you are satisfied with the

alignment.

Note: if your workpiece binds between

the planer shoe and fence / jig during operation a

1-2mm offset of the rear shoe (as stated above) will

eliminate this.

Re-check that the planer is level across the chassis

(Fig. 9) and make any necessary adjustments.

FITTING TO THE WORKCENTRE

Remove the Workcentre table and turn it upside

down.

Insert the M6 Flange nuts (14) into the underside of

the Nut Carriers (16) so that it locates fully inside

the cavity (Fig. 11)

With the flange of the nut facing up (toward you),

insert the nut carriers into the slots in the front and

rear table reinforcing ribs. They can be inserted

from either side of the slot (Fig. 11).

Loosely fit a short Coach Bolt (17) and Round Knob

(18) to the Front and Rear table brackets (19 and

20) (Fig. 12).

Fit the brackets to the nut carriers using a short M6

screw (12) and Washer (7). Push brackets in the

direction shown to take up any movement before

tightening (Fig. 13). Make sure the round knobs

face toward each other and the notched ends of the

brackets point outward.

FITTING THE PLANER TO THE CHASSIS

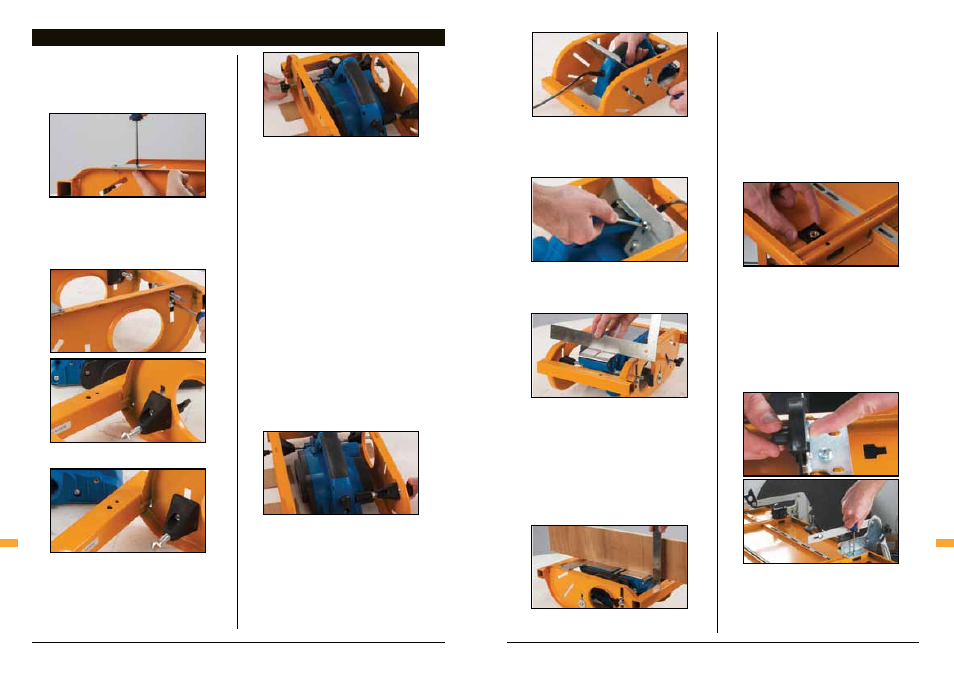

Fit the Alignment Plate (1) to the lower side of the

Planer Chassis (2) (flange outward) using the M4

Screws (3) and Flange Nuts (4). Tighten firmly with

a Phillips screwdriver (Fig. 1).

Fit the Front Clamps (5) to the chassis, using the

long M6 Screws (6), Washers (7) and Hex Nuts (8)

(the nuts locate inside the clamp bases) (Fig.2).

Do not tighten yet. Most planers mount using the

planers fence holes - an exception is shown in

(Fig.4).

Leave the clamps free to slide in their slots to

match the height of the planers fence hole.

Remove the 4 perforated cardboard packers from

the carton flaps. Sit the chassis on top of the

packers, as shown, and allow the heads of the

alignment plate screws to overhang the edge of

your worktable (Fig 5.).

Adjust your planer to ‘0’ (front and rear shoes in

line) and sit it flat on your assembly table with the

rear shoe touching the edge of the alignment plate.

Relocate the alignment plate to suit your planer if

required.

Push and tap the plastic Wing Knobs (9) onto the

hexagonal ends of the clamp bolt. Extend the

clamps, by tightening the wing knobs until the

conical ends locate into the planer fence holes

(Fig. 5) Ensure the cones locate exactly central

within the fence holes, otherwise they will alter the

planer alignment when fully tightened.

If everything appears correctly lined up, tighten the

Phillips screws holding the front clamp bases. Then

tighten the cones into the fence holes ensuring the

rear planer shoe remains in full contact with the

edge of the plate. DO NOT OVERTIGHTEN.

Fit the Rear Clamp (10) to the chassis using a

long M6 screw, (6) washer and hex nut. Fit the

wing knob and tighten the clamp into a location

which allows the clamp to align with the planer

handle (Fig. 6). Flip the orientation of the clamp if

necessary. If a suitable location cannot be found,

relocate the clamp into the lower slot and position

it further down the handle.

Tension the clamp until it just touches the planer

(Fig.6). Do not overtighten as this will skew the

planer alignment.

Fit the Handle Bracket (11) over the planer

handle and fasten it to the chassis using the short

M6 Screws (12), Large Washers (13), and M6

Flange Nuts (14). Ensure the planer is flat on your

work table, then hold the bracket against the planer

handle and tighten into position with a Phillips

screwdriver (Fig 7).

Assembly

Assembly

ASSEMBLY

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Fig. 10

Fig. 11

Fig. 12

Fig. 13