Troubleshooting – Triton TA184CSL User Manual

Page 14

14

GB

14

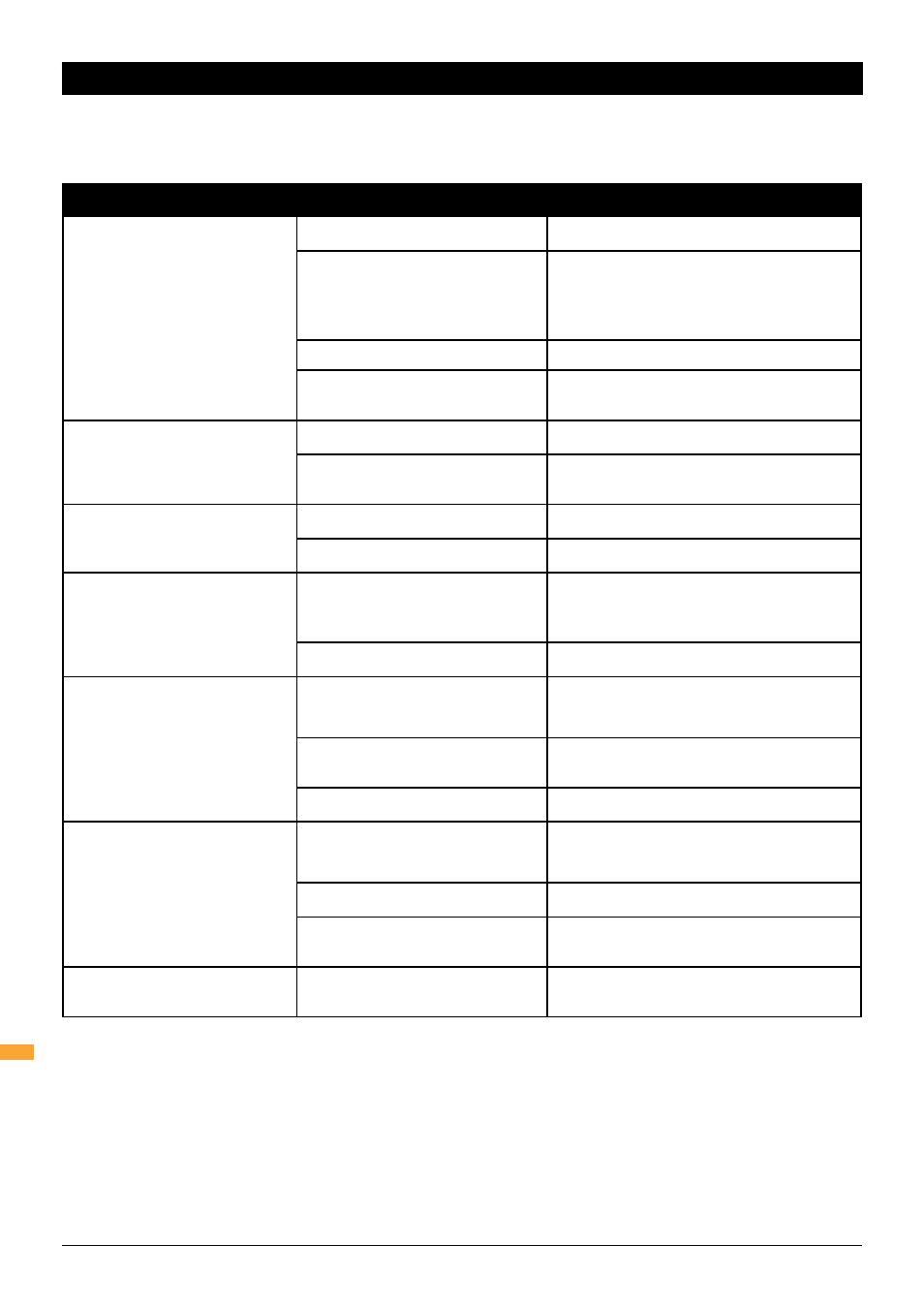

Troubleshooting

The following chart contains information designed to assist in diagnosing and resolving

saw problems.

TROUBLESHOOTING

If a problem cannot be resolved using the above advice do not tamper

with the saw - visit www.tritontools.com to find your nearest Triton office

for assistance.

** Visit www.tritontools.com to find your nearest authorised service centre.

SYMPTOM

POSSIBLE CAUSE

REMEDY

Saw will not operate

• No supply of power

• Check that power is available at source

• Brushes worn or sticking

• Disconnect power, open brush caps and

ensure brushes move freely in the holders.

Check whether the brushes require replac-

ing as outlined above.

• Trigger is faulty

• Contact Service Centre**

• Motor components open or short

circuited

• Contact Sevice Centre**

Saw runs slowly

• Blunt or damaged blade

• Re-sharpen or replace blade

• Motor is overloaded

• Reduce pushing force on saw. Ensure the

cut isn’t closing and pinching the blade.

Makes an unusual sound

• Mechanical obstruction

• Contact Service Centre**

• Armature has shorted sections

• Contact Service Centre**

Motor runs but blade won’t

spin

• Blade retaining nut is loose, or

reducing spacer incorrectly fitted.

• Tighten blade retaining nut. Ensure the

arbor reducing spacer and flange

washers are correctly fitted.

• Broken gear shaft or teeth

• Contact Service Centre**

Heavy sparking occurs inside

motor housing

• Brushes not moving freely

• Disconnect power, remove brushes, clean

or replace.

• Armature short circuited or open

circuited

• Contact Service Centre**

• Commutator surface not clean

• Contact Service Centre**

Retractable guard will not

close or is slow to close

• Return spring detached or broken • Re-attach or replace spring (use only

genuine Triton replacement parts).

• Guard is bent.

• Straighten it or contact Service Centre**.

• Mechanism fouled by sawdust.

• Clean and lightly lube fouled

mechanism.

Saw depth adjustment not

holding

• Depth locking lever requires

repositioning.

• Reposition the depth adjustment lever as

shown on page 9.