tekmar 421 Mixing Reset Module User Manual

Page 13

13 of 20

© 2007

D 421 - 08/07

Terminal Unit Defaults

When a terminal unit is selected, the control loads default

values for the mix design, mix maximum supply, and mix

minimum supply temperatures. The factory defaults can be

changed to better match the installed system.

•

• Locate the Mix terminal unit setting in the Adjust

menu.

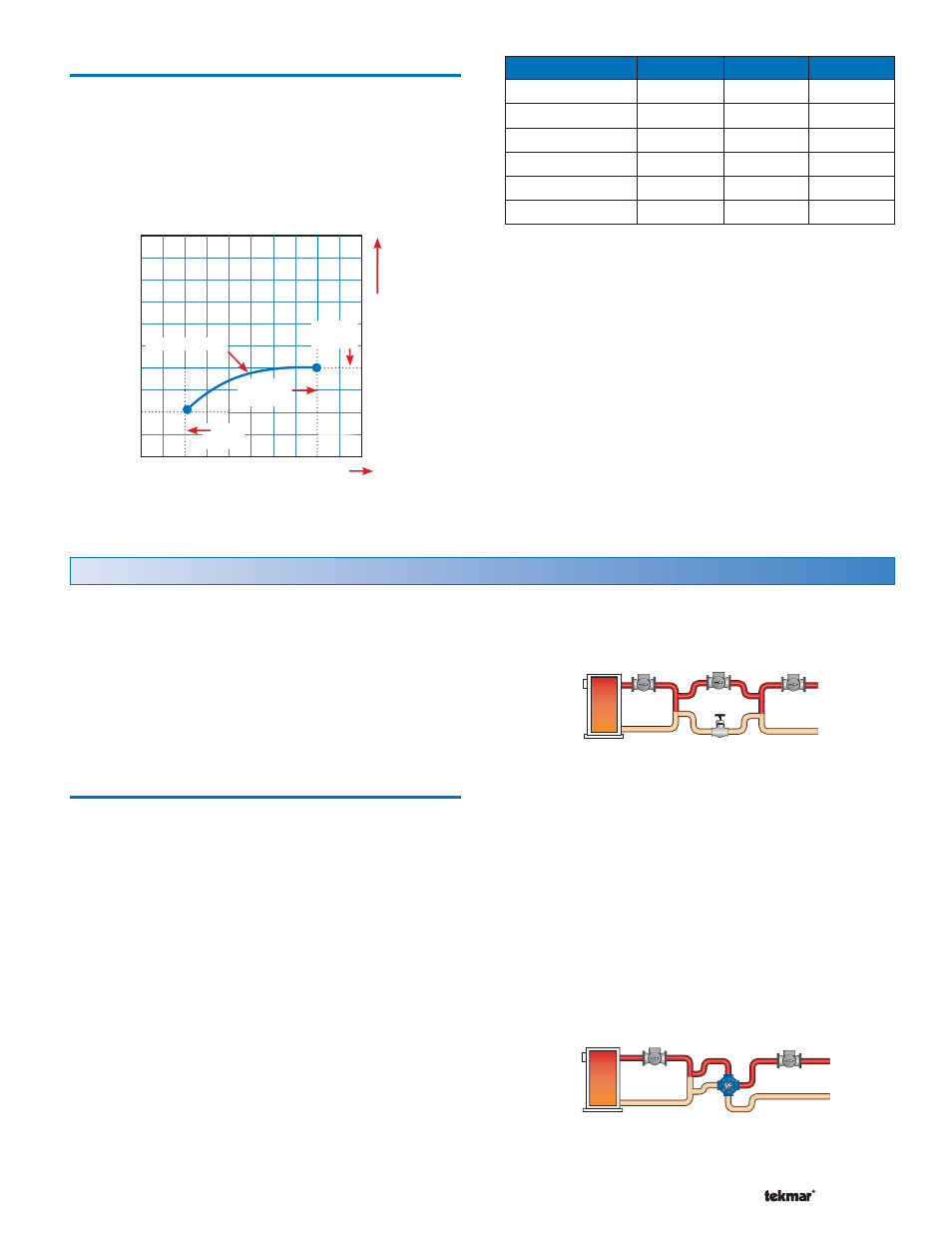

Mix Characterized Heating Curve

Terminal Unit

Mix

Design

Outdoor

Design

Mix

Indoor

Decreasing Outdoor Temperatures

Increasing Mix T

e

mperature

Terminal Unit

MIX DSGN

MIX MAX

MIX MIN

High Mass Radiant (1)

120°F (49°C)

140°F (60°C)

OFF

Low Mass Radiant (2)

140°F (60°C)

160°F (71°C)

OFF

Fancoil (3)

190°F (88°C)

210°F (99°C)

100°F (38°C)

Fin-Tube Convector (4)

180°F (82°C)

200°F (93°C)

OFF

Radiator (5)

160°F (71°C)

180°F (82°C)

OFF

Baseboard (6)

150°F (76°C)

170°F (77°C)

OFF

Mix Indoor Design

The Mix indoor design temperature is the indoor temperature

the heating designer picked while calculating the heat

loss for the building for the Mix water heated zones.

This temperature is typically 70°F (21.0°C). This setting

establishes the beginning of the Mix characterized heating

curve.

•

• Locate the Mix Indoor Design setting in the Adjust

menu.

Mix Design Temperature

The Mix design supply temperature is the mix supply

water temperature required to heat the zones when the

outdoor temperature is as cold as the outdoor design

temperature.

Mixing Operation

Section C

When tN4 thermostats are connected to a communication

bus assigned to mixing, the tN4 thermostat determines the

necessary water temperature to heat the zone and then

requests this water temperature from the reset control.

The 421 responds by indicating a Mix Demand symbol in

the display, then determines the highest heat requirement

of all the zones, and then operates the mixing device to

maintain a mix target water temperature.

Mix Mode

A mixing device allows the control to reduce the boiler

water temperature down to a lower water temperature. A

mixing device when used with a boiler sensor also allows

the control to protect the boiler from sustained flue gas

condensation and thermal shock.

The Mix outputs are built-in to the 421. The type of mixing

device is selected using the Mix Mode setting. The mixing

devices that can be selected are variable speed injection

(VAr) and floating action (FLt).

•

• Locate the Mix Mode setting in the Adjust menu.

Variable Speed Injection

A standard wet rotor circulator can be connected to the

Variable Speed output on the control. The control increases

or decreases the power output to the circulator when there

is a requirement for mixing. The circulator speed varies to

maintain the correct mixed supply water temperature at

the mix supply sensor. For correct sizing and piping of the

variable speed injection circulator, refer to essay E 021.

A visual indication of the current variable speed output is

displayed in the LCD in the form of a bar graph.

Floating Action

A floating action actuator motor can be connected to the

control on the Opn and Cls terminals. The control pulses

the actuator motor open or close to maintain the correct

supply water temperature at the mix supply sensor when

there is a requirement for mixing. The mixing valve that the

actuator is connected to can be either a 2-way, 3-way or

4-way valve. A visual indication as to whether the control is

currently opening or closing the mixing valve is displayed

in the LCD with the words OPN and CLS while viewing

the Mix Supply or Mix Target temperatures. Also, a visual

indication of the current position of the valve is displayed

in the form of a bar graph.