Basic installation – tekmar 367 Zone Control User Manual

Page 6

6

UnOccupied Temperature

When the 367 is in UnOccupied mode, the

UnOccupied light is turned on and the

UnOccupied dial is used to set the desired temperature within the UnOccupied zones.

Note If the RTU dial for an UnOccupied zone is set below the

UnOccupied dial, the 367

continues to use the RTU dial as the desired temperature within that zone.

Individual Zone Selection

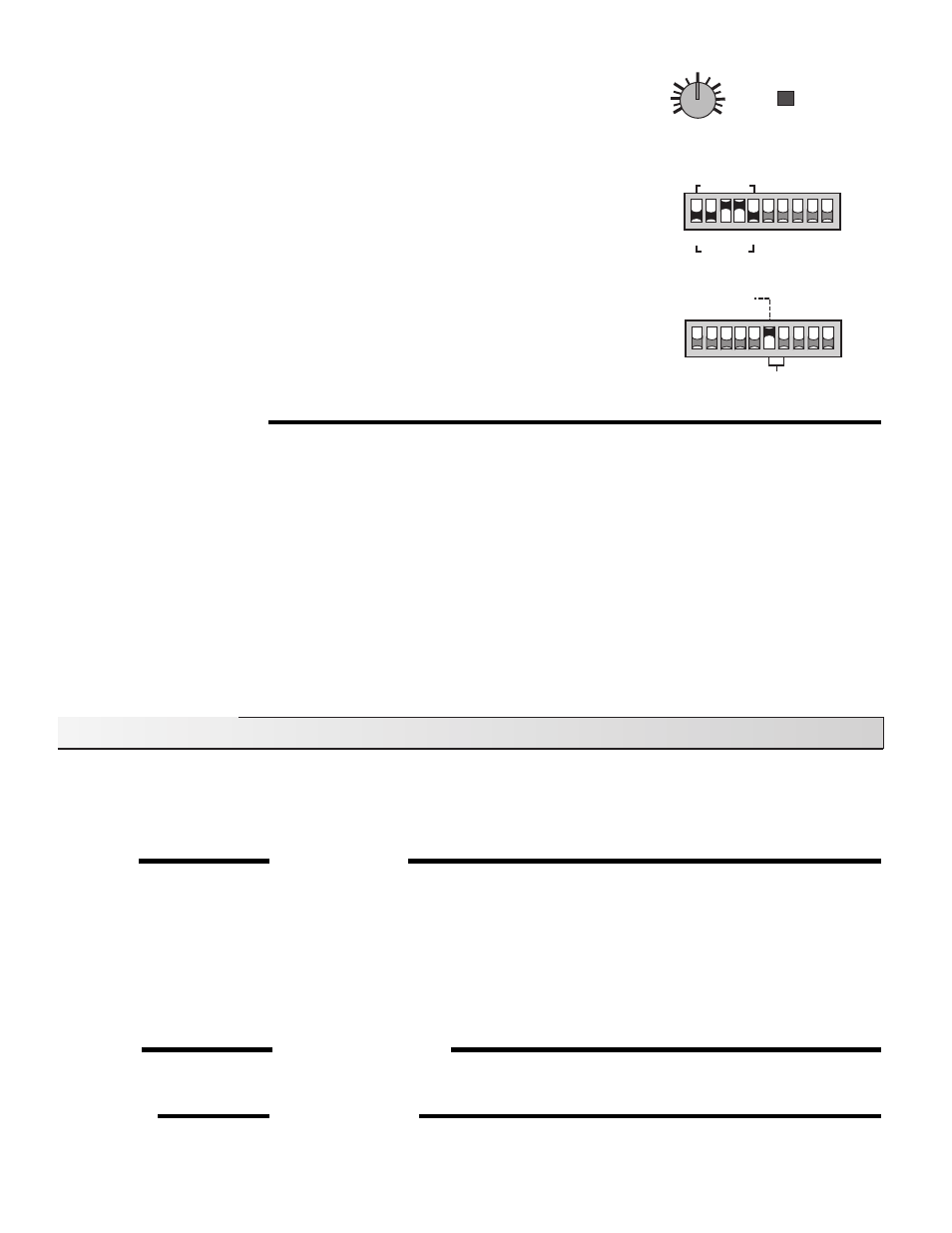

The DIP switch on the 367 is used to select which zones are switched into UnOccupied

mode. If the DIP switch for a specific zone is set to

Occ / UnOcc, that zone is switched

into UnOccupied mode whenever the 367 receives an UnOccupied signal. If the DIP

switch for a specific zone is set to

Occ. only, the zone remains in the Occupied mode at

all times.

Optimum Start / Stop

The Optimum Start / Stop feature is enabled when the DIP switch is set to

Optimum Start.

The 367 turns on the

Optimum Start / Stop light each time the first zone enters its delay

or recovery period. Either the tekmar Timer 031 or the built in 24 hr. Timer on the 367 can

be used with the Optimum Start / Stop feature. The tekmar Timer 031 has a DIP switch

which must be set to

Optimum Start / Stop in order to synchronize the timer with the 367

Optimum Start / Stop function. For more information on the Timer 031 consult the Data

Brochure D 031.

SYSTEM PUMP OPERATION

The

System Pump light is turned on every time the relay contact between terminals System Pmp — System Pmp (1 & 2) is closed. During

heating operation, the system pump operates whenever any zone requires heat. If thermal motor zone valves are used, the system pump

is held off for the first three minutes of the zone cycle in order to give the zone valve sufficient time to open. The system pump may also

operate for an additional purge period once the zone relays are turned off.

Pump / Valve Exercising

The zone valves, zone pumps and system pump are exercised to help prevent corrosion from building up and subsequently jamming

the equipment. Every three days the 367 runs through the following exercising procedure.

Exercising Procedure

The 367 first exercises the zone valves or pumps. If a zone valve or zone pump has not been operated in the past 3 days, the 367

turns on the zone relay for 10 seconds.

Note The zone relay exercising time is increased to 3 minutes if the DIP switch is set to

Thermal Motor.

After the zone valves or pumps have been exercised, the 367 exercises the system pump. If the system pump has not operated

in the past 3 days, the 367 turns on the

System Pmp relay for 10 seconds.

Once the exercising procedure is complete, the 367 returns to its normal operating sequence.

Basic Installation

Caution

Improper installation and operation of this control could result in damage to the equipment and possibly even personal injury.

It is your responsibility to ensure that this control is safely installed according to all applicable codes and standards. This

electronic control is not intended for use as a primary limit control. Other controls that are intended and certified as safety

limits must be placed into the control circuit.

STEP ONE

GETTING READY

Check the contents of this package. If any of the contents listed are missing or damaged, please contact your wholesaler or tekmar sales

representative for assistance.

Type 367 includes:

• One Zone Control 367

• Data Brochures D 367, D 001

• Application Brochures A 367

Other information available:

• Essays

Note Carefully read the details of the Sequence of Operation sections in all applicable brochures to ensure that you have chosen the

proper control for your application.

STEP TWO

MOUNTING THE BASE

Remove the control from its base by pressing down on the release clip in the wiring chamber and sliding the control upwards. The base

is then mounted in accordance with the instructions in the Data Brochure D 001.

STEP THREE

ROUGH-IN WIRING

All electrical wiring terminates in the control base wiring chamber. The base has standard 7/8" (22 mm) knockouts which accept common

wiring hardware and conduit fittings. Before removing the knockouts, check the wiring diagram and select those sections of the chamber

with common voltages. Do not allow the wiring to cross between sections as the wires will interfere with safety dividers which should

Off

Optimum Start

UnOccupied

70

°

F

(21

°

C)

40

(4)

100

(38)

UnOccupied

Zone

Occ/UnOcc

1,2

4

3

Occ. only

5

6