L-gage, Lt3 long-range time-of-flight sensor, Two discrete outputs – Banner L-GAGE LT3 Series User Manual

Page 2: Theory of operation, Programming, Response speed, Sensor setup, Window limits

L-GAGE

®

LT3 Long-Range Time-of-Flight Sensor –

Two Discrete Outputs

2

P/N 68503 rev. C

Banner Engineering Corp.

•

Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

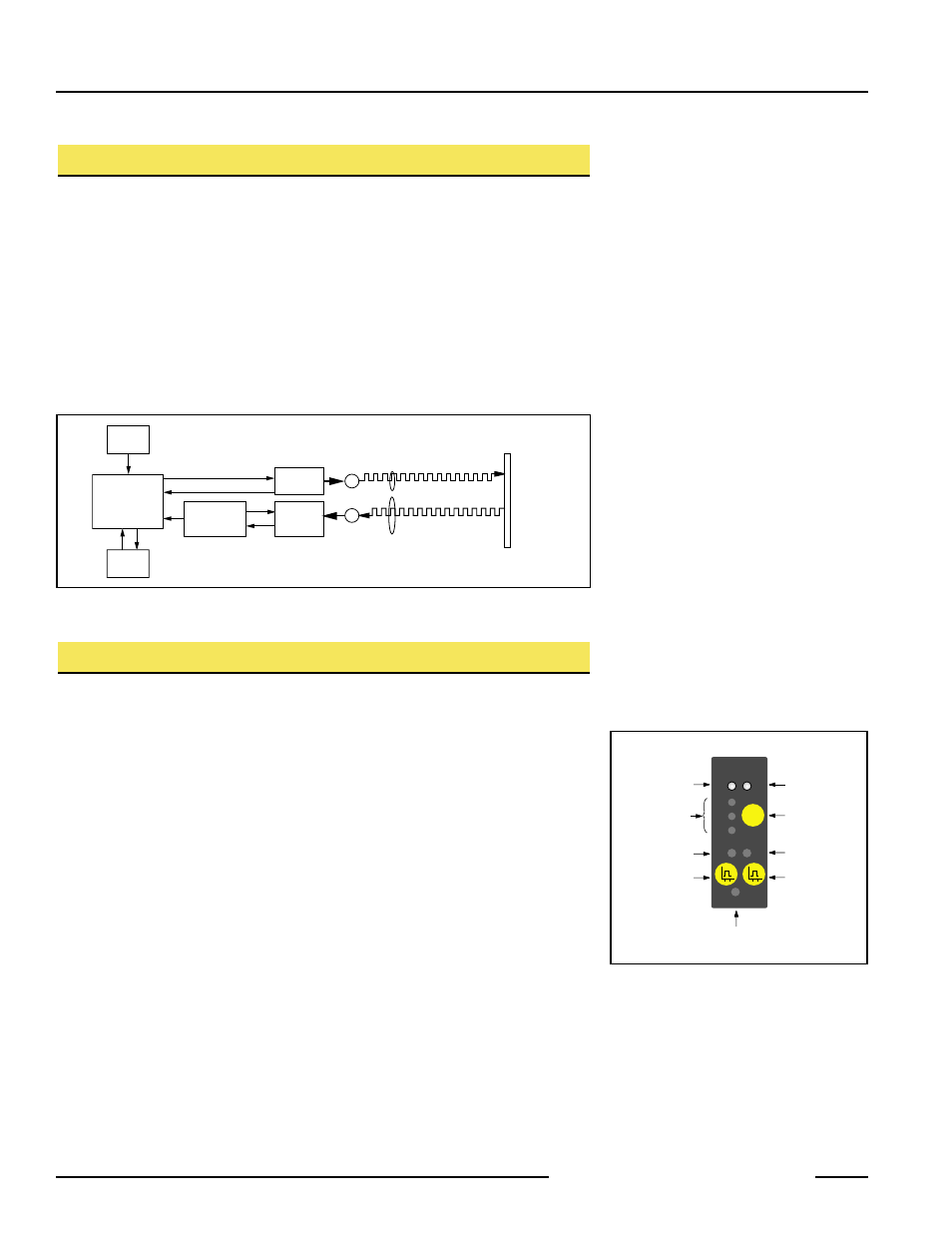

Theory of Operation

A short electrical pulse drives a semiconductor laser diode to emit a pulse of light. The

emitted light is collimated through a lens, which produces a very narrow laser beam.

The laser beam bounces off the target, scattering some of its light through the sensor’s

receiving lens to a photodiode, which creates an electrical pulse. The time interval

between the two electrical pulses (transmitting and receiving the beam) is used to

calculate the distance to the target, using the speed of light as a constant.

Multiple pulses are evaluated by the sensor’s microprocessor, which calculates the

appropriate position value. The discrete (switched) output energizes whenever the

target is located between the user-programmed discrete window limits. Window

limits for both discrete outputs may be the same, or they may be programmed

independently.

Programming

Response Speed

Prior to setting window limits, use the sensor’s Speed push button to toggle between

the three response speed settings. The selected speed will be indicated by one of the

three Response Speed indicator LEDs (see Figure 2). See Specifications for further

information.

Sensor Setup

Allow 30 minutes after power-up to allow the sensor’s internal temperature to stabilize,

before operating or attempting to program the sensor. If the sensor will be used in

applications where the temperature is several degrees higher or lower than ambient,

allow the sensor to stabilize in that condition before programming the window limits.

(Range will decrease as the sensor warms up.)

The laser enable feature allows the sensor to be continually powered, and enabled only

when being used. This eliminates the need for the extended warm-up period between

uses.

The sensor’s red Signal LED indicates the condition of the received signal from the

object being measured. When programming window limits, this LED must be ON solid

(not flashing) for the sensor to accept the setting. On diffuse-mode models, to ensure

that the received signal will not be marginal during operation, move the target object

300 mm beyond the furthest desired set point during setup, and verify that the signal

LED is still ON solid.

Window Limits

Window limits may be taught to the sensor in several ways. The following methods

(beginning on page 4) describe the programming procedures using the push buttons on

the top of the sensor or via remote programming (remote TEACH).

Microprocessor

User

Interface

Emitter

Circuitry

Analog

Signal

Processing

Time-of-Flight

Engine

Output

Circuitry

Laser

Emitter

Lenses

Target

Receiver

Element

E

R

Figure 1. Theory of operation

SIGNAL

OUTPUT

FAST

MED

SLOW

TEACH

POWER

SPEED

Signal LED

Output LED

Response Speed

Indicators

Discrete Output 1

Teach LED

Discrete Output 2

Teach LED

Discrete Output 1

Programming

Push Button

Discrete Output 2

Programming

Push Button

Power ON/OFF LED

Response Speed

Push Button

D

D

Figure 2. Sensor features