Specifications, 2 and in, Background reflectivity and placement – Banner Q40 Series User Manual

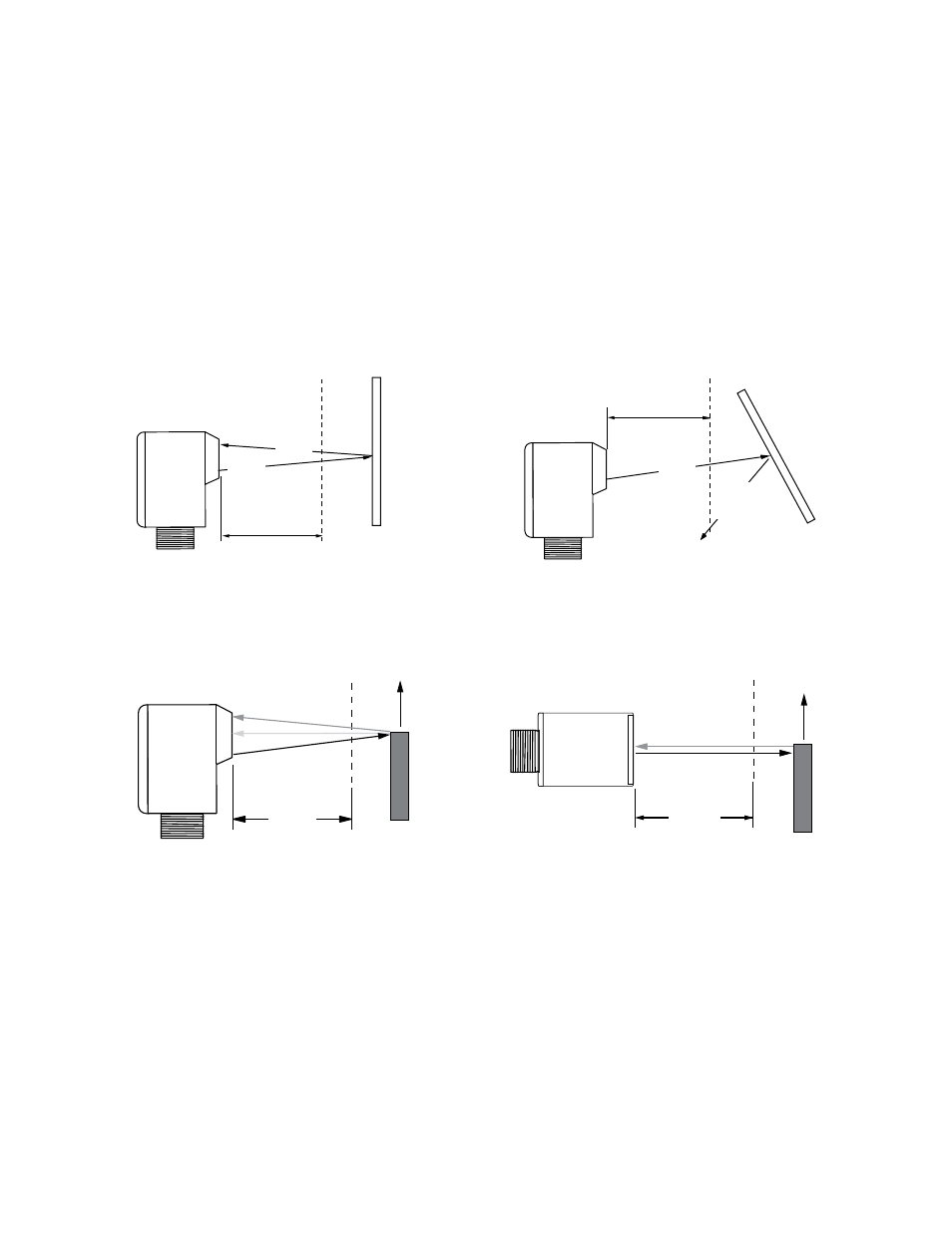

Page 3: Figure 3. reflective background - problem, Figure 4. reflective background - solution, Figure 5. object beyond cutoff - problem, 3, these elements align vertically; in, Figure 6. object, Beyond cutoff - solution

on page 2). The sensing axis becomes important in situations like those illustrated in

Figure 5. Object beyond cutoff - problem

on page 3 and

Object beyond cutoff - solution

on page 3.

Background Reflectivity and Placement

Avoid mirror-like backgrounds that produce specular reflections. False sensor response will occur if a background surface reflects the sensor’s light more strongly to the

near detector (R1) than to the far detector (R2). The result is a false ON condition (

Figure 3. Reflective background - problem

on page 3). Use of a diffusely-reflective

(matte) background will cure this problem. Other possible solutions are to angle the sensor or angle the background (in any plane) so the background does not reflect back

to the sensor (see

Figure 4. Reflective background - solution

on page 3). Position the background as far beyond the cutoff distance as possible.

An object beyond the cutoff distance, either moving or stationary (and when positioned as shown in

Figure 5. Object beyond cutoff - problem

on page 3), can cause

unwanted triggering of the sensor because it reflects more light to the near detector than to the far detector. The problem is easily remedied by rotating the sensor 90°

(

Figure 6. Object beyond cutoff - solution

on page 3) to align the sensing axis horizontally. The object then reflects the R1 and R2 fields equally, resulting in no false

triggering. A better solution, if possible, may be to reposition the object or the sensor.

Unwanted triggering of the sensor from an object beyond the cutoff can also be caused by attempting to sense a small object that is moving perpendicular to the sensor

face, or by an object moving through the off-center position shown in

Figure 5. Object beyond cutoff - problem

on page 3. Making the object larger, centering the sensor

relative to the object, or rotating the sensor to place the sensing axis perpendicular to the longer dimension of the object (

Figure 6. Object beyond cutoff - solution

on page

3) will solve the problem.

E

R2

R1

Q40 sensor

E = Emitter

R1 = Near Detector

R2 = Far Detector

Fixed Sensing Field

Strong

Direct

Reflection

to R1

Core of

Emitted

Beam

Cutoff

Distance

Reflective

Background

Figure 3. Reflective background - problem

E

R2

R1

Q40 sensor

E = Emitter

R1 = Near Detector

R2 = Far Detector

Cutoff

Fixed Sensing Field

Strong Direct

Reflection

Away

From Sensor

Core of

Emitted

Beam

Cutoff

Distance

Reflective

Background

Figure 4. Reflective background - solution

R1 = Near Detector

R2 = Far Detector

E = Emitter

Reflective

Background

or

Moving Object

E

R2

R1

Q40 sensor

Fixed

Sensing

Field

Cutoff

Distance

Figure 5. Object beyond cutoff - problem

E = Emitter

R2 = Far Detector

R1 = Near Detector

E, R2, R1

Q40 sensor

Fixed

Sensing

Field

Cutoff

Distance

Reflective

Background

or

Moving Object

Figure 6. Object beyond cutoff - solution

Specifications

Supply Voltage and Current

10 to 30V dc (10% max. ripple)

Supply current (exclusive of load current):

Emitters: 25 mA

Receivers: 20 mA

Polarized Retroreflective: 30 mA

Fixed-Field: 35 mA

Supply Protection Circuitry

Protected against reverse polarity and transient voltages

Repeatability

Opposed mode: 375 μs

Retro and Fixed-Field: 750 μs

Repeatability and response are independent of signal strength

Indicators

Two LEDs (Green and Yellow)

Green ON steady: power to sensor is ON

Green flashing: output is overloaded

Yellow ON steady: N.O. output is conducting

Yellow flashing: excess gain marginal (1 to 1.5x) in light condition

Q40 Sensors - dc-Voltage Series Installation Guide

P/N 116167 Rev. A

www.bannerengineering.com - tel: 763-544-3164

3