Hookups, Fixed-field mode overview, Excess gain – Banner Q40 Series User Manual

Page 2: Set-up tips

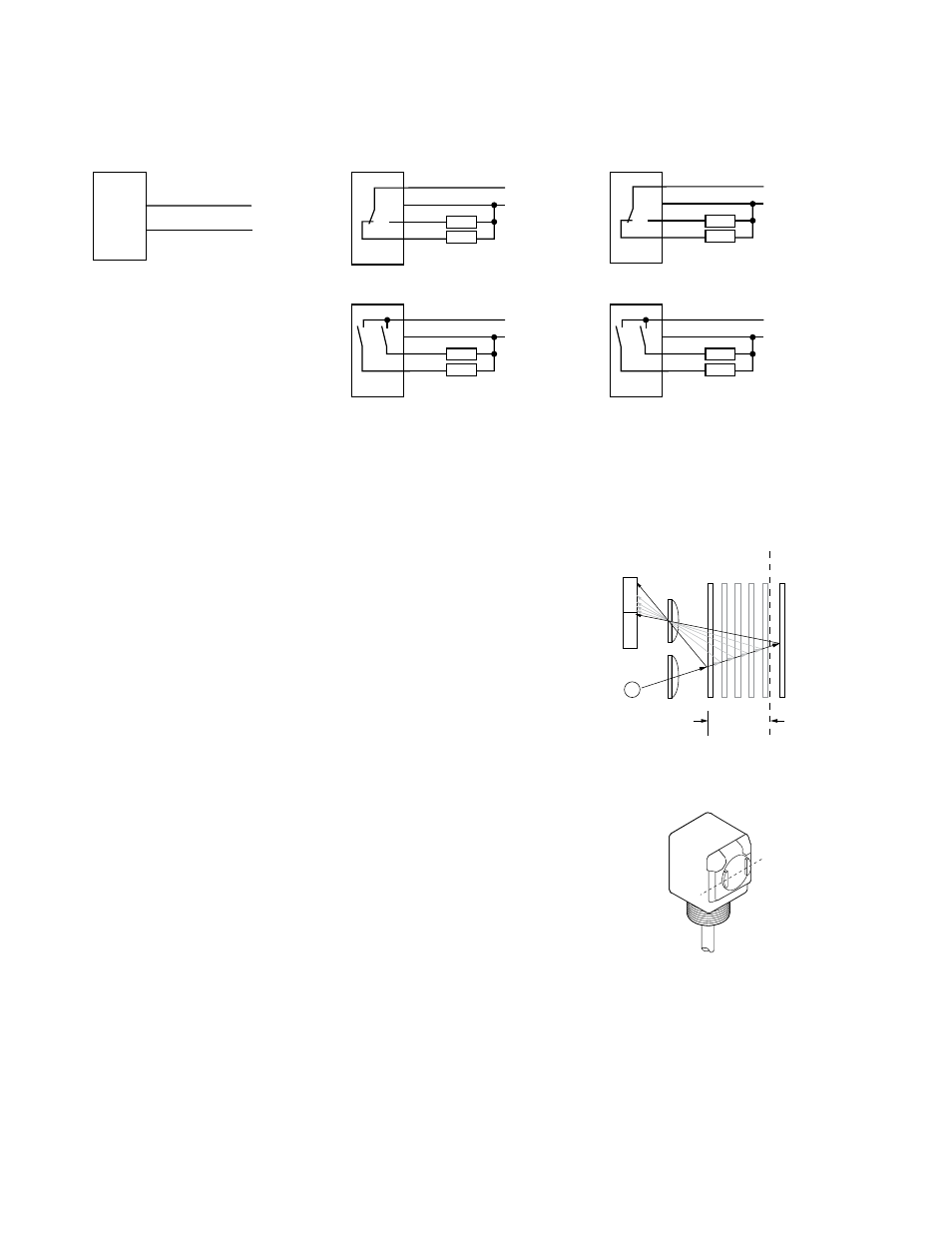

Hookups

NPN (Sinking) Outputs

PNP (Sourcing) Outputs

Cabled Emitters

Standard Hookup

Standard Hookup

bn

bu

10-30V dc

+

–

bn

bu

wh

bk

+

10 - 30V dc

–

Load

Load

bu

bn

wh

bk

+

10 - 30V dc

–

Load

Load

Alarm Hookup

Alarm Hookup

NOTE: QD hookups are functionally identical.

bn

bu

wh

bk

10 - 30V dc

Load

Alarm

+

–

bn

bu

wh

bk

10 - 30V dc

Load

Alarm

+

–

Fixed-Field Mode Overview

Q40 Series self-contained fixed-field sensors are small, powerful, infrared diffuse mode sensors with far-limit cutoff. The high excess gain of these sensors makes it possi-

ble for them to detect objects of low reflectivity. The fixed-field design makes them ideal for detecting a part or surface that is directly in front of another surface, while

ignoring the surface in the background.

Excess Gain

The excess gain curves for these products are available in the Photoelectric Sensors catalog or on the Ban-

ner website. They show excess gain vs. sensing distance for sensors with 200 mm, 400 mm, and 600 mm

(8", 16", and 24") cutoffs. Maximum excess gain for all models occurs at a lens-to-object distance of about

40 mm (1.57"). Sensing at or near this distance will make maximum use of each sensor’s available sensing

power.

Backgrounds and background objects must always be placed beyond the cutoff distance.

These excess gain curves were generated using a white test card of 90% reflectance. Objects with reflectiv-

ity of less than 90% reflect less light back to the sensor, and thus require proportionately more excess gain

in order to be sensed with the same reliability as more reflective objects. When sensing an object of very

low reflectivity, it may be especially important to sense it at or near the distance of maximum excess gain.

The effects of object reflectivity on cutoff distance, though small, may be important for some applications.

Sensing of objects of less than 90% reflectivity causes the cutoff distances to be “pulled” slightly closer to

the sensor. For example, an excess gain of 1 for an object that reflects 1/10 as much light as the 90% white

card is represented by the heavy horizontal graph line at excess gain = 10. An object of this reflectivity

results in far limit cutoffs of approximately 190 mm, 250 mm, and 390 mm (7.48", 9.84", and 15.4") for the

200 mm, 400 mm, and 600 mm (8", 16", and 24") cutoff models, respectively.

For highest sensitivity, the sensor-to-object distance should be such that the object will be sensed at or near

the point of maximum excess gain. The background must be placed beyond the cutoff distance. Following

these two guidelines makes it possible to detect objects of low reflectivity, even against close-in reflective

backgrounds.

R1

R2

Lenses

Object

A

Object B

or

Background

Sensing

Range

Cutoff

Distance

E

Receiver

Elements

Near

Detector

Far

Detector

Emitter

Object is sensed if amount of light at R1

is greater than the amount of light at R2

Figure 1. Fixed-field Concept

Sensing

Axis

R2

R1

E

As a general rule, the most reliable sensing of an object

approaching from the side occurs when the line of ap-

proach is parallel to the sensing axis.

Figure 2. Fixed-field sensing axis

Set-Up Tips

In the drawings and discussion in

on page 2 and in

Background Reflectivity and Placement

on page 3, the letters E, R1, and R2 identify how the sensor’s

Figure 3. Reflective background - problem

3,

Figure 4. Reflective background - solution

Figure 5. Object beyond cutoff - problem

on page 3, these elements align vertically; in

on page 3, they align horizontally. Note how the pattern on the sensor’s lens helps to define the sensing axis of the sensor (

Q40 Sensors - dc-Voltage Series Installation Guide

2

www.bannerengineering.com - tel: 763-544-3164

P/N 116167 Rev. A