CommScope ConQuest Conduit Construction User Manual

Page 53

ConQuest

®

Toneable Conduit

™

7.2

Coupling

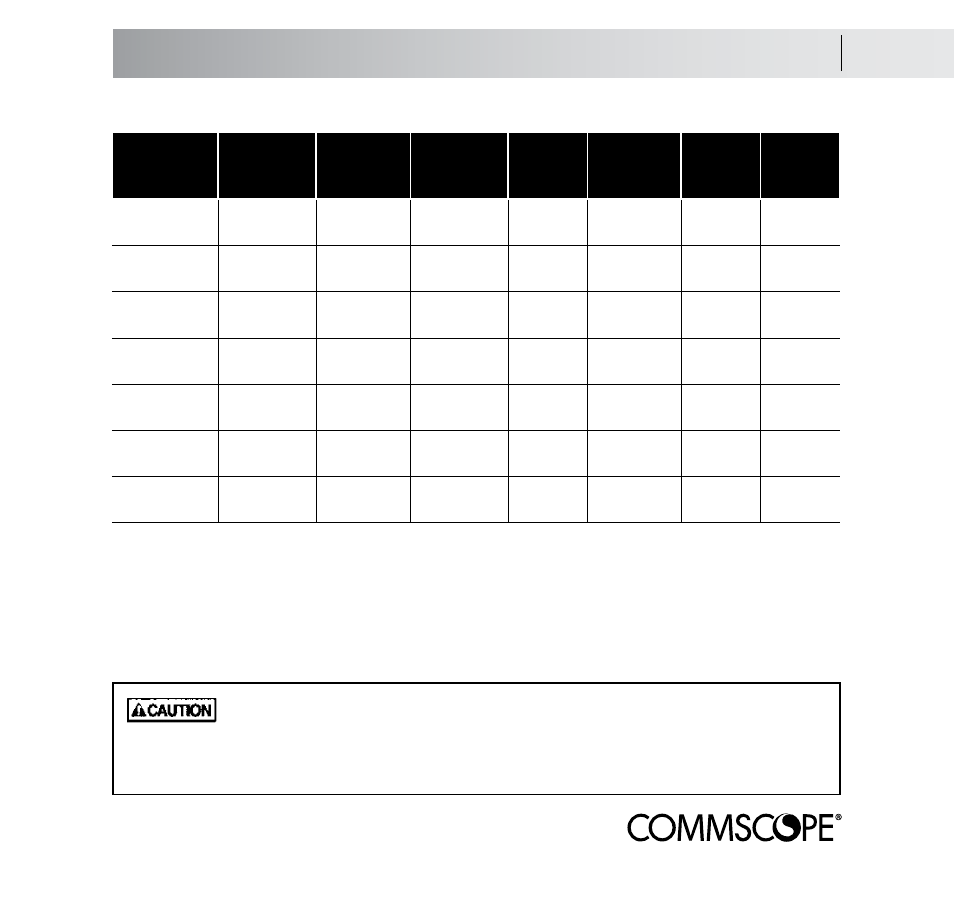

Table 1

Conduit Size

CU-Clad

Wire Size

AWG

Outside

Diameter

(inches)

Wall Thick-

ness

(inches)

Nominal

Inner

Diameter

(inches)

Min. Bend

Radius

Unsupported

(inches)

Max.

Pulling

Tension

(lbs.)

Weight

(lb/ft)

3/4" SDR 11 18

1.050 ±

0.005

0.095 ±

0.020

0.84

20

687

0.128

1.00" SDR

13.5

18

1.315 ±

0.007

0.097 ±

0.020

1.101

26

894

0.166

1.25" SDR

13.5

18

1.660 ±

0.008

0.123 ±

0.020

1.394

34

1,425

0.263

1.50" SDR

13.5

18

1.900 ±

0.010

0.141 ±

0.020

1.598

38

1,867

0.344

2.00" SDR 11 18

2.375 ±

0.012

0.216 ±

0.026

1.917

48

3,515

0.642

2.00" SDR

13.5

18

2.375 ±

0.012

0.176 ±

0.021

2.002

48

2,917

0.534

2.00" SCH

40

18

2.375 ±

0.012

0.154 ±

0.020

2.047

48

2,579

0.473

Continuity tests while the conduit is on the reel can be performed with a volt-ohm meter. Continuity testing after the

conduit has been placed can be performed according to the following procedure: Place a locator transmitter at one

end of the run, and connect directly to the wire, use a halo clamp around the conduit, or set the transmitter over the

location of the buried conduit and turn it on. Go to the far end and see if the locator signal can be picked up with the

receiver. If so, continuity exists. If not, follow the signal away from the transmitter until it disappears. That signifies either

a break in the wire or a depth beyond the locator capability.

The tone wire may develop induced foreign voltage during certain field conditions. Adjacent

or parallel power lines may cause a voltage level that can be hazardous. Always test for foreign power prior to

stripping or working with the tone wire, using acceptable test equipment. The wire is 18 AWG copper-clad steel

rated at 30.041 ohm/1,000 ft. 68°F.