CommScope ConQuest Conduit Construction User Manual

Page 44

Pull Calculations

Maximum pull lengths, pulling tension at the end of a straight section of conduit, pulling tension at the end of a bend,

and sidewall pressure can be calculated quite easily. However, it is important to remember that these calculations are

only estimates. This is due to the significant variances in construction practices and lack of accounting for:

• Undulations, rising, falling, and straightness of the straight sections of conduit

• Cable stiffness

• Lubrication, coefficients of friction, foreign debris in conduit

Calculating A Complete Run

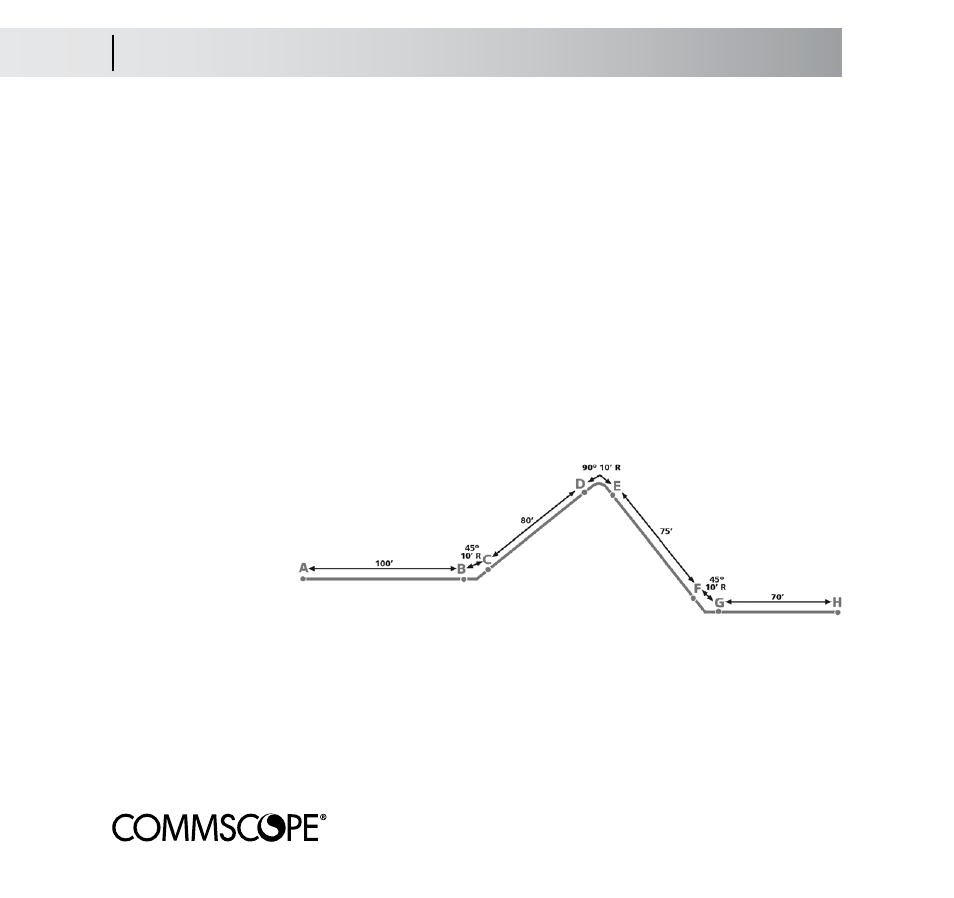

An example provides a clear illustration of how to calculate a complete run and understand the effects of bends on

pulling tensions and sidewall pressure. Calculations have been performed in both directions. In the first calculation, the

run has the reel setup at point ‘A’ with the cable being pulled from point ‘H’. The second calculation is the opposite with

the reel setup at point ‘H’ and the cable being pulled from point ‘A’. The cable used is QR715. The formulas used for

calculating this run are located in the Appendix.

The resulting calculations for this run are:

Pulling from A to H =

64 pounds pulling tension

Pulling from H to A =

54 pounds pulling tension

NOTE: The direction of pull and distances between bends can have a dramatic impact on pulling

tensions.

5.6

Pulling Cable into Conduit

Pull Calculations