Bendix Commercial Vehicle Systems AD-SP SYSTEM PURGE AIR DRYER 10/04 User Manual

Page 6

6

CARTRIDGE

BOLT

PURGE

VOLUME

DELIVERY

PORT

CHECK

VALVE

(BLACK)

PURGE

VALVE

TURBO

CUT-OFF

VALVE

SUPPLY

PORT

CONTROL

PORT

OIL

SEPARATOR

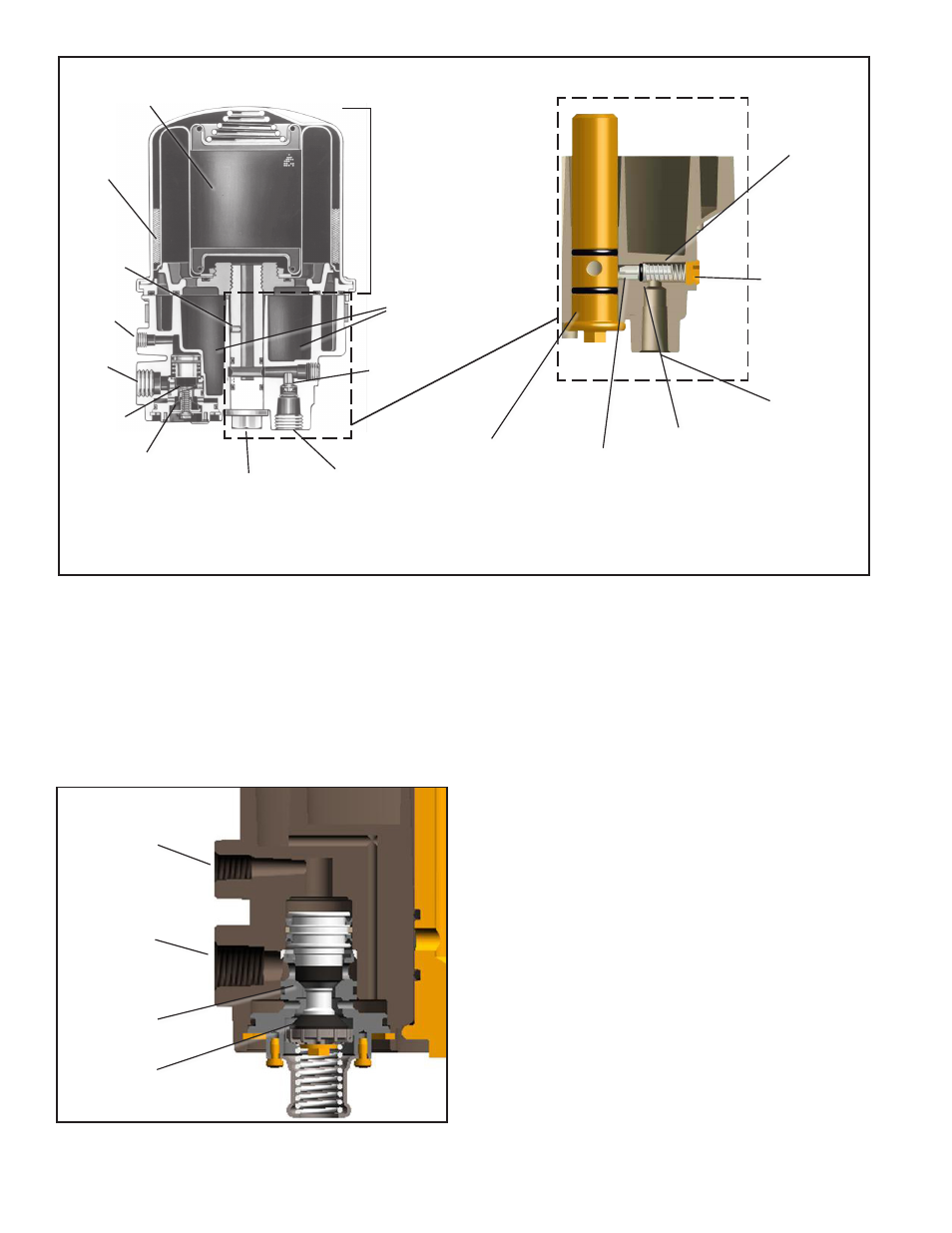

FIGURE 4 -

BENDIX

®

AD-IP

®

AIR DRYER SECTIONAL VIEW

DESICCANT

BED

PURGE

ORIFICE

DESICCANT

CARTRIDGE

New Style End Cover - Horizontal Delivery Check Valve

SPRING

O-RING

PIPE PLUG

CARTRIDGE

BOLT

DELIVERY

PORT

Old Style End Cover -Vertical Delivery Check Valve

CHECK VALVE

(WHITE)

FIGURE 5 -

AD-IP

®

INTEGRAL PURGE AIR DRYER TURBO

CUT-OFF

SUPPLY

PORT

TURBO

CUT-OFF

VALVE

CONTROL

PORT

PURGE

VALVE

The actual reactivation of the desiccant drying bed begins

as dry air flows from the purge volume through the purge

orifice in the desiccant cartridge bolt, then through the

center of the bolt and into the desiccant bed. Pressurized

air from the purge volume expands after passing through

the purge orifice; its pressure is lowered and its volume

increased. The flow of dry air through the drying bed

reactivates the desiccant material by removing the water

vapor adhering to it. Generally 30 seconds are required for

the entire purge volume of a standard Bendix

®

AD-IP

®

air

dryer to flow through the desiccant drying bed.

The delivery check valve assembly prevents air pressure in

the brake system from returning to the air dryer during the

purge cycle. After the 30 second purge cycle is complete

the desiccant has been reactivated or dried. The air dryer

is ready for the next charge cycle to begin. However the

purge valve will remain open and will not close until air

brake system pressure is reduced and the governor signals

the compressor to charge the system.

TURBO CUT-OFF FEATURE

(Refer to Figure 5)

The primary function of the turbo cut-off valve is to

prevent loss of engine turbocharger air pressure through

the AD-IP air dryer in systems where the compressor

intake is connected to the engine turbocharger. The turbo

cut-off valve also removes the “puffing” of air out the open

purge exhaust when a naturally aspirated, single cylinder

compressor, equipped with an inlet check valve, is in use.