Bendix, Ad-ip, Air dryer troubleshooting chart – Bendix Commercial Vehicle Systems AD-SP SYSTEM PURGE AIR DRYER 10/04 User Manual

Page 23

23

BENDIX

®

AD-IP

®

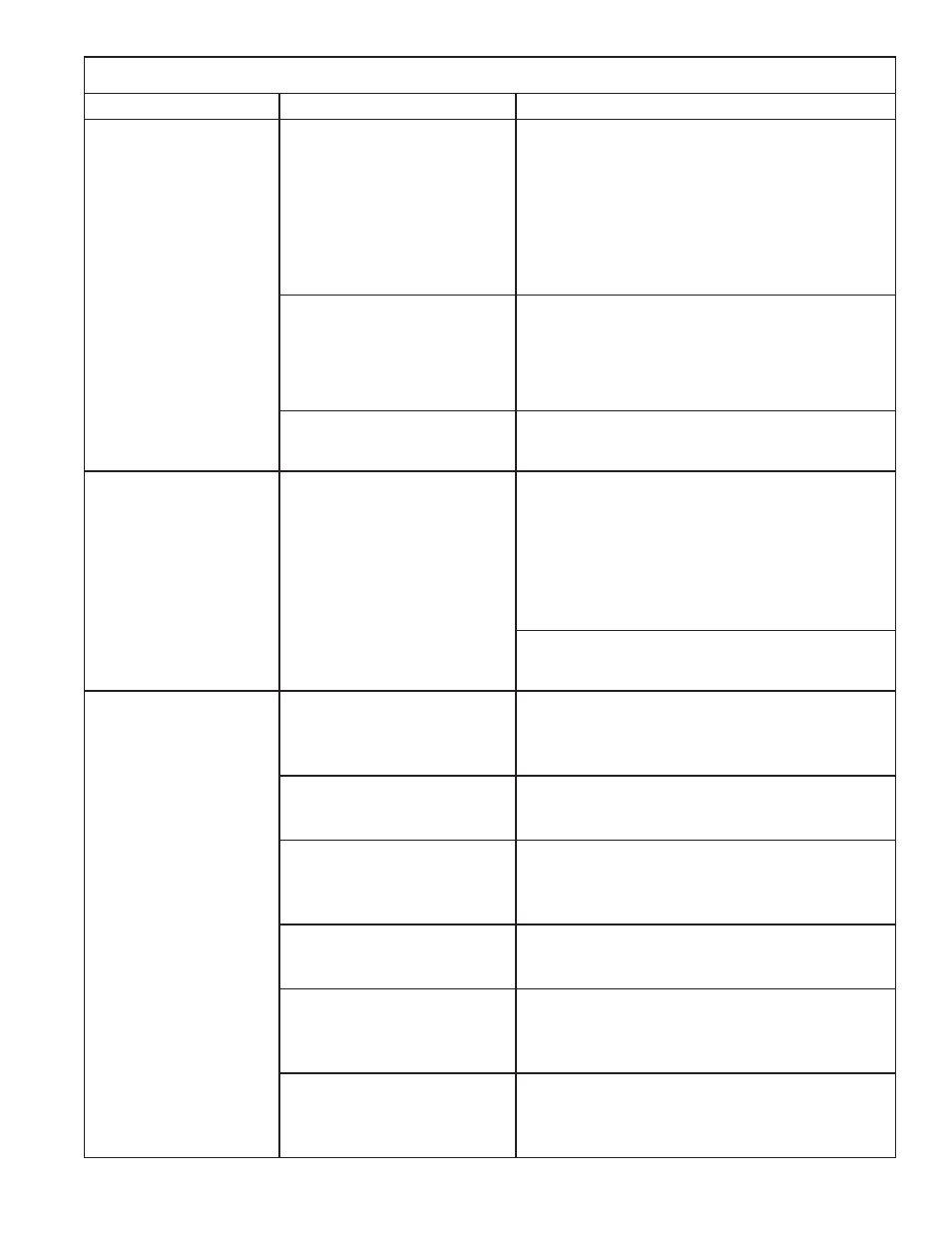

AIR DRYER TROUBLESHOOTING CHART

SYMPTOMS

CAUSE

REMEDY

2. Water and/or oil in

the supply or service

reservoir (continued).

G. Compressor malfunction.

G. If you found excessive oil present in the service

reservoir and you did not find any issues above,

the compressor may be passing oil. Test the

compressor using the Bendix

®

BASIC

™

cup method

as described in the Bendix compressor service

manual and referred to in Appendix A, Table A,

column 5.

Replace compressor. If still under warranty, follow

normal warranty process.

H. Air by-passes desiccant

cartridge assembly.

H. If the vehicle uses a Holset

®

compressor, inspect

the feedback check valve for proper installation and

operation. When replacing the desiccant cartridge,

make sure the desiccant cartridge assembly is

properly installed and the sealing rings are in place

on the mounting surface of the desiccant cartridge.

I. Desiccant requires

replacement.

I. Replace the desiccant cartridge assembly.

Refer to Appendix A, Table A columns 3 & 4 for

recommended intervals.

3. Oil present at the air

dryer purge exhaust

or cartridge during

maintenance.

A. Air brake charging system is

functioning normally.

A. Air dryers remove water and oil from the air brake

charging system. A small amount of oil is normal.

Check that the regular maintenance is being

performed and that the amount of oil in the air tanks

(reservoirs) is within the acceptable range shown on

the BASIC cup (see also column 5 of Appendix A,

Table A). Replace the air dryer cartridge as needed

and return the vehicle to service.

B. The Bendix

®

AD-IP

®

PuraGuard

®

oil coalescing air

dryer removes more oil from the brake system than

the standard Bendix

®

AD-IP

®

air dryer.

4. Safety valve on the air

dryer “popping off” or

exhausting air.

A. Restriction between air dryer

and supply (first) reservoir.

A. Check to determine if air is reaching the supply

reservoir. Inspect for kinked tubing or hose. Check

for undrilled or restricted hose or tubing fittings and

repair or replace as needed.

B. Air dryer safety valve

malfunction.

B. Verify the relief pressure is at the vehicle or

component manufacturer specifications. Replace

if malfunctioning.

C. Desiccant cartridge

maintenance required.

C. Refer to Table A and column 3. Check the

compressor for excessive oil passing and/or correct

compressor installation. Repair or replace as

necessary. Replace the desiccant cartridge.

D. Malfunctioning discharge

check valve in the end cover

of the AD-IP air dryer.

D. Test to determine if air is passing through the check

valve. Repair or replace.

E. Excessive pressure

pulsations from the

compressor. (Typical single

cylinder type.).

E. Increase the volume in the discharge line by

increasing the length or diameter. Add a ping tank

(small reservoir).

F. Governor malfunction.

Missing or restricted

governor control line

installation.

F. Test the governor operation and/or inspect the

control line leading from the governor UNL

(unloader) port to the air dryer control port.