Bendix, Ad-ip, Air dryer troubleshooting chart – Bendix Commercial Vehicle Systems AD-SP SYSTEM PURGE AIR DRYER 10/04 User Manual

Page 21

21

BENDIX

®

AD-IP

®

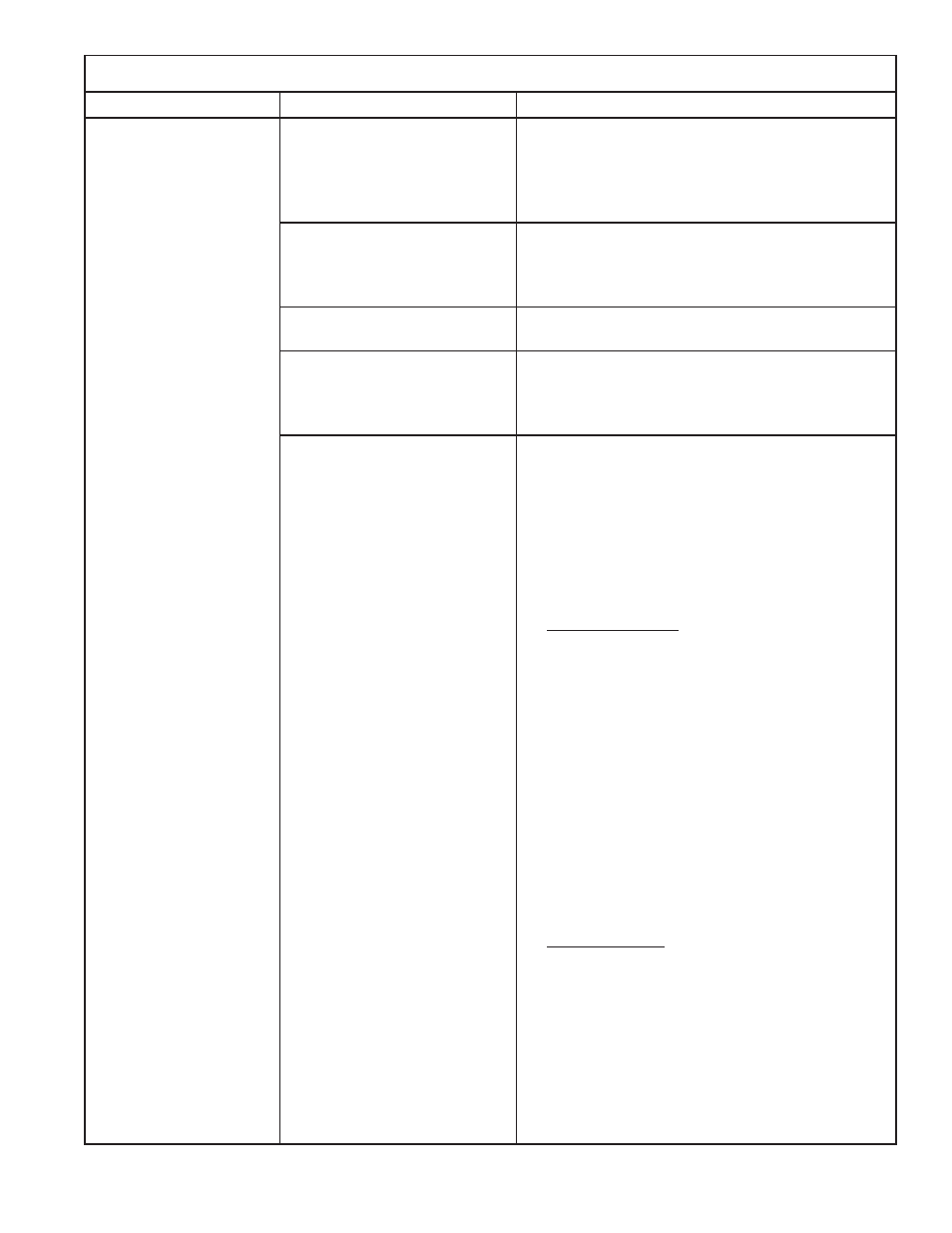

AIR DRYER TROUBLESHOOTING CHART

SYMPTOMS

CAUSE

REMEDY

2. Water and/or oil in

the supply or service

reservoir.

A. Improper discharge line

length or improper line

material. The maximum air

dryer inlet temperature is

exceeded.

A. Refer to Connecting the Air Lines section as well

as Appendix A, Table A columns 1 & 2 then check

line size and length.

B. Air system charged from an

outside air source (outside

air not passing through air

dryer).

B. If the system has an outside air fill provision, outside

air should pass through the air dryer. This practice

should be minimized.

C. Air dryer not purging (see

Symptom #5).

C. See Symptom #5.

D. Purge (air exhaust) time

insufficient due to excessive

system leakage (see causes

for Symptom #1).

D. Check causes and remedies for Symptom #1.

E. Excessive air usage, duty

cycle too high - Air dryer not

compatible with the vehicle

air system requirement

(Improper air dryer/vehicle

application).

Note: Duty Cycle is the ratio

of time the compressor spends

building air to total engine

running time. Air compressors

are designed to build air

(run “loaded”) up to 25% of

the time. Higher duty cycles

cause conditions that affect

air brake charging system

performance which may

require additional maintenance.

Factors that add to the duty

cycle are: air suspension,

additional air accessories,

use of an undersized

compressor, frequent stops,

excessive leakage from fittings,

connections, lines, chambers or

valves, etc.

E. See Appendix A, Table A, column 1, for the

recommended compressor sizes. If the compressor

is “too small” for the vehicle vocation (for example,

where a vehicle’s vocation has changed or service

conditions exceed the original vehicle or engine OE

spec’s) then upgrade the compressor.

Note: The costs incurred (e.g. installing a larger

capacity compressor, etc.) are not covered under

the original compressor warranty.

Charge Cycle Time - The Bendix

®

AD-IP

®

air dryer

is designed to provide clean, dry air for the brake

system. When a vehicle’s air system is used to

operate non-brake air accessories it is necessary

to determine that; during normal, daily operation the

compressor should recover from governor “cut-in”

to governor “cut-out” (usually 100 psi to 120 psi) in

90 seconds or less at engine RPM’s commensurate

with the vehicle vocation. If the recovery time

consistently exceeds this limit, it may be necessary

to “bypass” the air accessory responsible for the

high air usage. An example of where a by-pass

system would be required is when the compressor

is used to pressurize a tank trailer for purposes of

off-loading product. Consult your local authorized

Bendix parts outlet or sales representative for

additional information.

Purge Cycle Time - During normal vehicle operation,

the air compressor

must remain unloaded for a

minimum of 30 seconds. This minimum purge

time is required to ensure complete regeneration

of the desiccant material. If the purge time is

consistently less than the minimum, an accessory

by-pass system must be installed. Consult your

local authorized Bendix

®

parts outlet or sales

representative for additional information.