Operation – Bendix Commercial Vehicle Systems AD-SP SYSTEM PURGE AIR DRYER 10/04 User Manual

Page 4

4

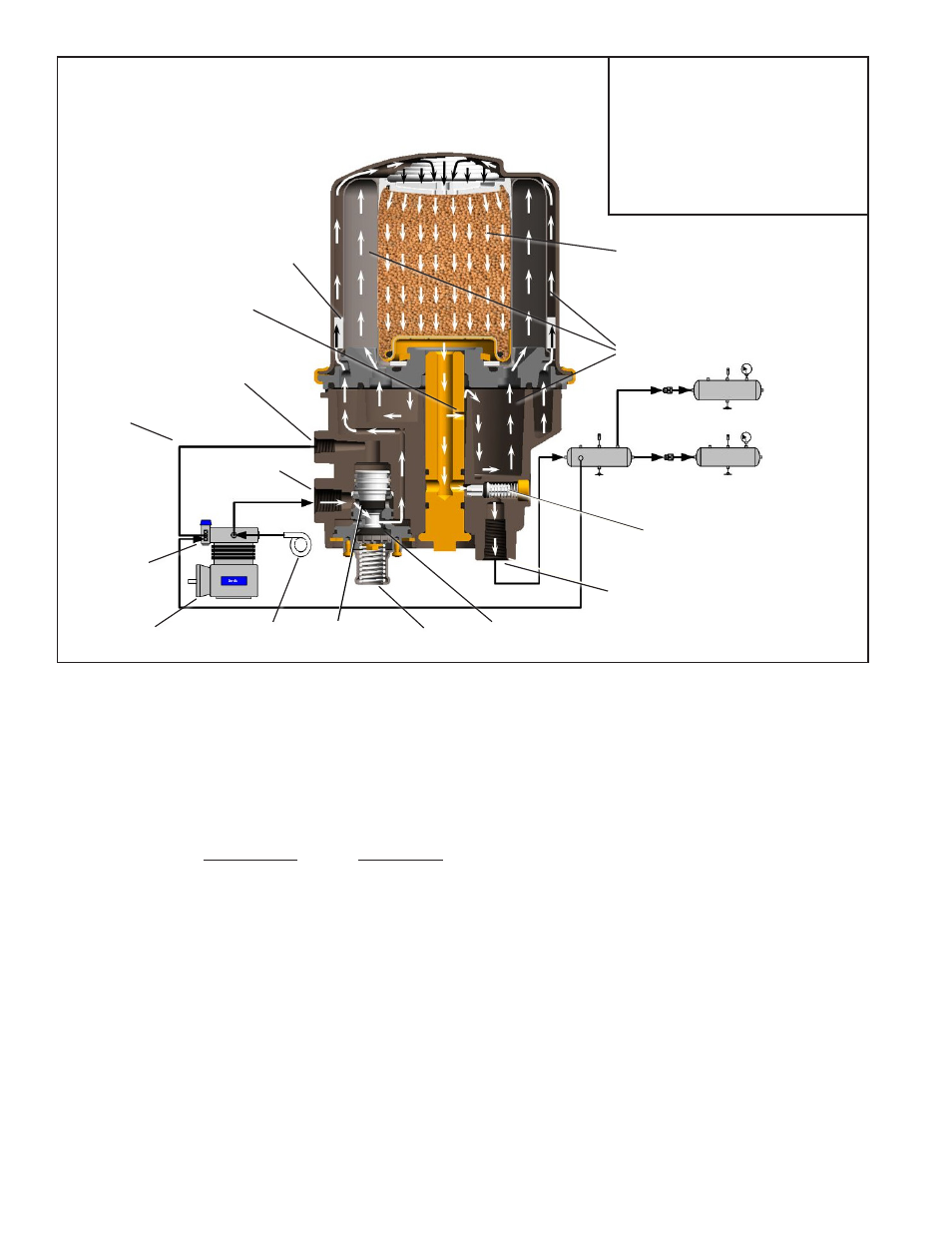

FIGURE 2 -

BENDIX

®

AD-IP

®

INTEGRAL PURGE AIR DRYER CHARGE CYCLE

OPERATION

GENERAL

Note: Unless otherwise stated in this manual, the Bendix

®

AD-IP

®

air dryer refers to both the standard and Bendix

®

AD-IP

®

PuraGuard

®

oil coalescing air dryer. The AD-IP air

dryer alternates between two operational modes or “cycles”

during operation: the Charge Cycle and the Purge Cycle.

The following description of operation is separated into

these “cycles” of operation.

CHARGE CYCLE

(Refer to Figure 2)

When the compressor is loaded (compressing air)

compressed air — along with oil, oil vapor, water and water

vapor — flows through the compressor discharge line to the

supply port of the air dryer body.

As air travels through the end cover assembly, its direction

of flow changes several times, reducing the temperature,

causing contaminants to condense and drop to the bottom

or sump of the air dryer end cover.

After exiting the end cover, the air flows into the desiccant

cartridge. Once in the desiccant cartridge the air first flows

through an oil separator, located between the outer and

inner shells of the cartridge. The separator removes water

in liquid form as well as liquid oil and solid contaminants.

Air, along with the remaining water vapor, is further cooled

as it exits the oil separator and continues to flow upward

between the outer and inner shells. Upon reaching the top

of the cartridge the air reverses its direction of flow and

enters the desiccant drying bed. Air flowing down through

the column of desiccant becomes progressively drier as

water vapor adheres to the desiccant material in a process

known as “ADSORPTION.” The desiccant cartridge using

the adsorption process typically removes most of the water

vapor from the pressurized air.

Dry air exits the bottom of the desiccant cartridge and flows

through the center of the bolt used to secure the cartridge

to the end cover. Air flows down the center of the desiccant

cartridge bolt, through a cross drilled passage and exits

the air dryer delivery port through the delivery check valve.

DESICCANT

BED

DELIVERY

CHECK VALVE

PURGE

VOLUME

DISCHARGE

PORT

EXHAUST

PURGE

VALVE

TURBO

CUT-OFF VALVE

ENGINE

TURBO

COMPRESSOR

GOVERNOR

PURGE

CONTROL

LINE

CONTROL

PORT

SUPPLY

PORT

OIL

SEPARATOR

PURGE

ORIFICE

Note 1:

The Bendix

®

AD-IP

®

air dryer and reservoir

system purge piston has a purge control

channel drain. This allows any condensation

in this area to flow past a diaphragm in the

top of the purge piston and out through a

channel in the middle of the central bolt of

the purge assembly to be drained. During

the purge cycle this drain is closed.